Summary

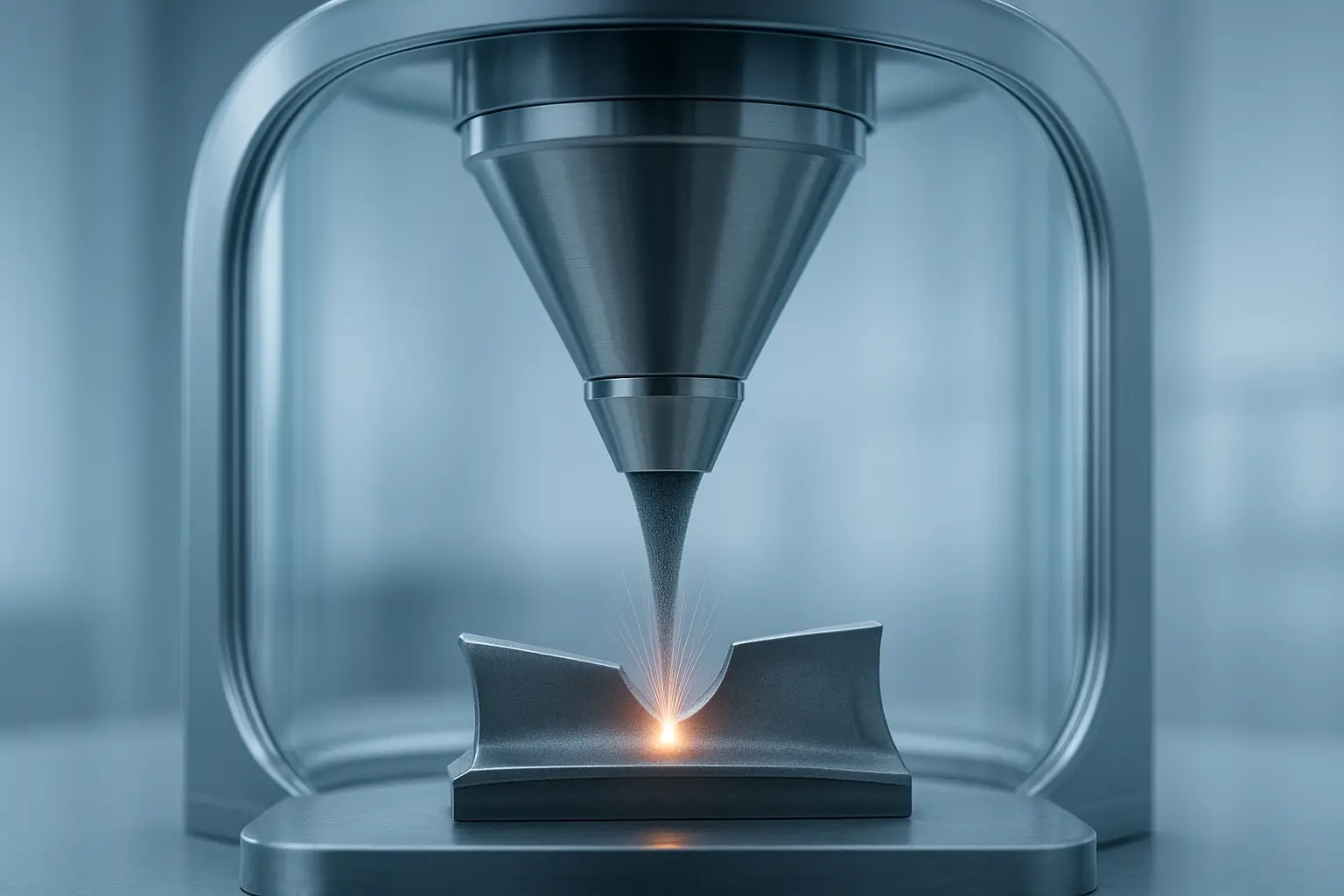

Laser Engineering Net Shaping (LENS) is an advanced metal additive manufacturing technology classified as a direct energy deposition (DED) process. In LENS, a high-powered laser (typically 500 W–4 kW) creates a melt pool into which fine metal powder is injected, building dense, near‑net‑shape parts with precision. Its key strengths include high repair capability for critical components, exceptional material density, and fine accuracy (0.002 in XY). [1][2]

Historical Background

LENS technology was developed at Sandia National Laboratories in Albuquerque, New Mexico, as a solution for rapid prototyping and repair of metal components. The technology was first licensed to Optomec in 1997, marking its commercialization; a foundational US patent (6046426) was issued in 2000. LENS originated from efforts to move beyond traditional subtractive techniques and meet industrial needs for precision, repair, and the creation of new, complex metal parts. From its inception, LENS was envisioned as a repair-and-build tool, addressing costs and lead times for sectors such as aerospace and defense. [3][4]

Technical Principles

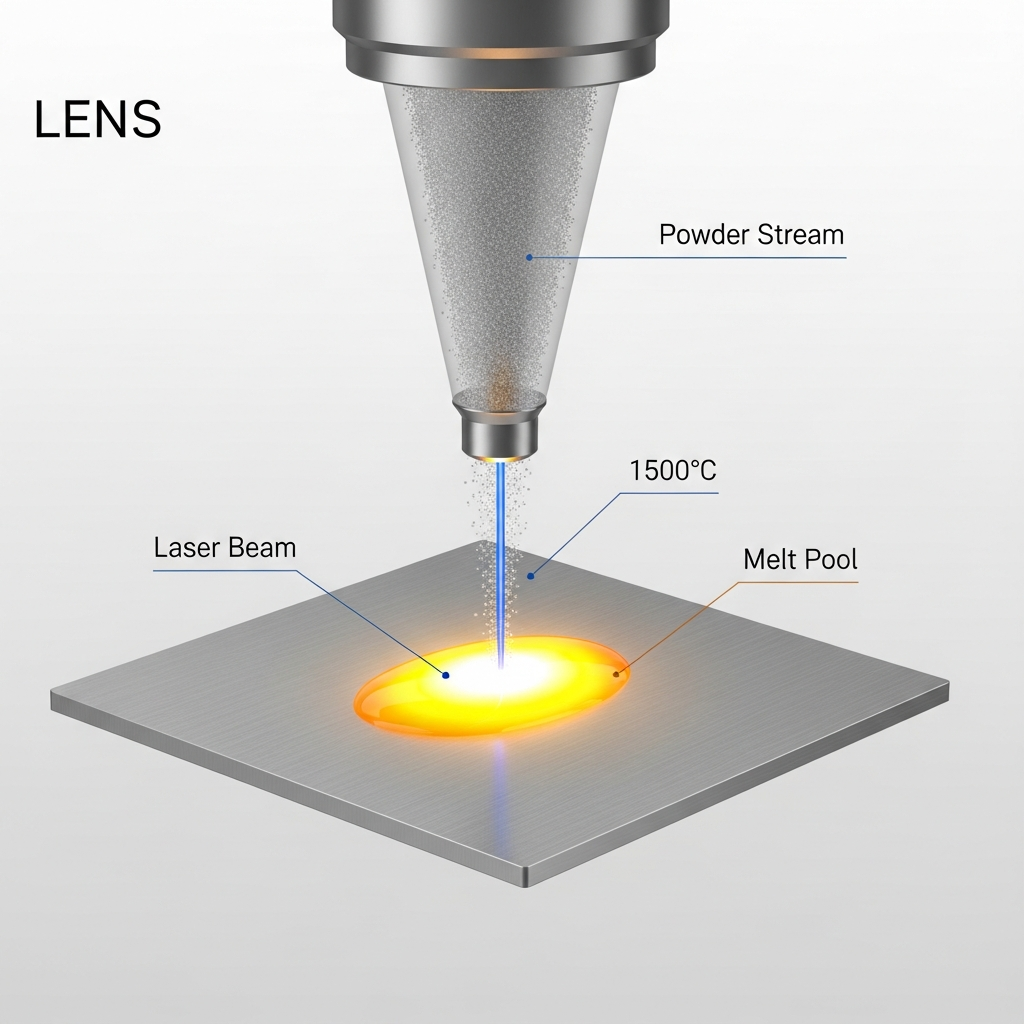

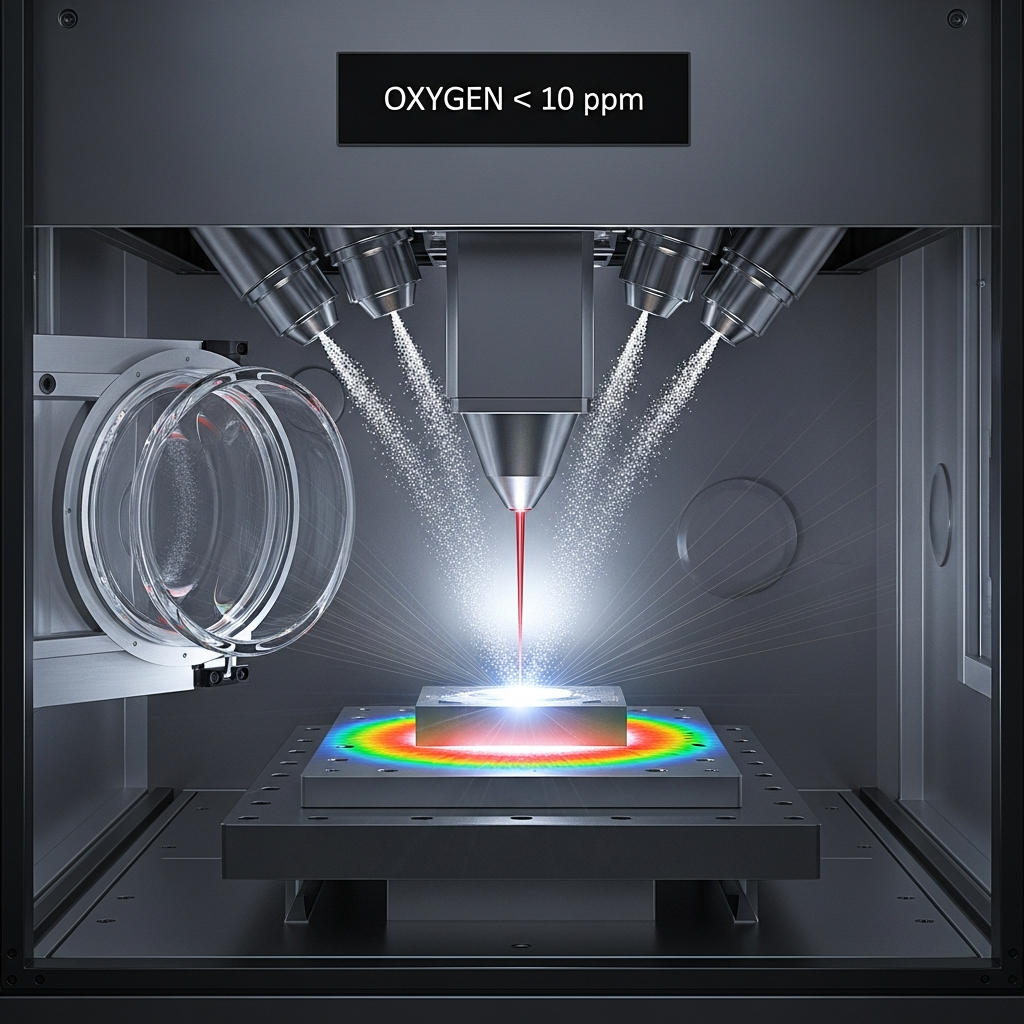

LENS operates by focusing a laser beam to form a small melt pool on a metal substrate, then injecting metallic powder—typically less than 150 μm in diameter—directly into this region. The entire process takes place inside a sealed chamber or shroud, where oxygen and moisture are controlled below 10 ppm to prevent contamination. [5][6]

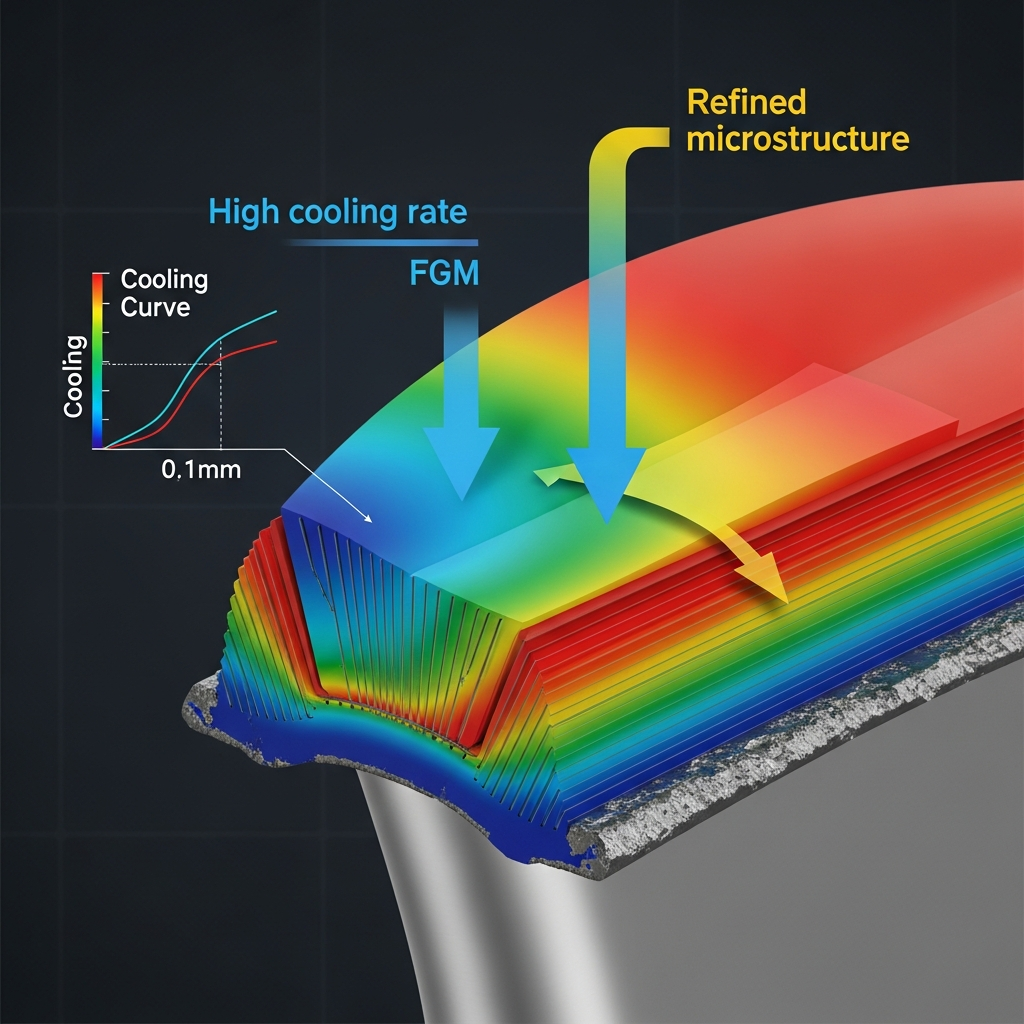

The LENS process utilizes high-powered lasers, typically ranging from 500 W to 4 kW, to deliver energy to the substrate and precisely melt the incoming powder feed. With X/Y resolution accuracy of 0.002 in and Z resolution of 0.020 in, LENS systems are capable of fabricating intricate geometries. During deposition, the rapid solidification yields cooling rates from 10²–10³ K/s (with some reports of 1,000–5,000 °C/s), which enables tailored microstructures and enhances mechanical properties. A typical LENS build goes through these numbered steps:

- Substrate preheating and system purge with inert gas.

- Focused laser melts substrate locally.

- Powder feed system injects metallic particles to melt pool.

- Controlled solidification as laser moves, building layer-by-layer.

- Monitoring and feedback systems adjust parameters for consistency.

Management of these parameters is critical, as altering cooling rates and laser input allows for the fabrication of functionally graded materials and the optimization of microstructure for application-specific requirements. [1][5][7]

System Types and Performance

LENS systems are available in multiple configurations tailored to part size and industrial integration. For example, the Optomec LENS 850 system features an 18 in × 18 in × 42 in (457 mm × 457 mm × 1,067 mm) build envelope, supporting large-scale manufacturing and repair. In terms of material performance, ceramic parts fabricated by LENS can reach densities of approximately 94% as-built, increasing to about 97% after post-heat treatment. LENS supports both functionally graded material builds and dense alloys, with options for complete OEM machines or modular print engines for integration into existing lines. [2][6]

| System | Work Envelope | X/Y Resolution | Z Resolution | Typical Applications |

|---|---|---|---|---|

| LENS 750 | Smaller than LENS 850 | 0.002 in | 0.020 in | R&D, medical, tool repair |

| LENS 850 | 18 in × 18 in × 42 in | 0.002 in | 0.020 in | Large parts, aerospace repair |

Applications

LENS is widely used for the repair and refurbishment of aerospace turbine blades, industrial tooling, and even biomedical implants requiring biocompatible metals. Its ability to add material to worn or damaged components means it plays a vital role in minimizing downtime and extending the service life of expensive parts. Manufacturers also exploit LENS for building functionally graded materials, where a part transitions gradually from one alloy composition to another within a single build, allowing for tailored mechanical or thermal properties.

Key application sectors:

- Aerospace (repair and manufacturing)

- Energy/turbine maintenance

- Medical implants and devices

- Tooling and die manufacturing

- Defense industry [8][2]

Research Updates

Recent research on LENS focuses on advanced microstructure control through cooling rate management and software-driven process optimization. Machine learning (ML) tools, such as Adaptive Intelligent Design for Engineered Deposition (AIDED), now leverage in situ data for predictive control—recent experiments report achieving material densities above 99.9% with high predictive accuracy. Improvements in software allow for better feedback and part qualification, fine-tuning not only density but residual stress and phase composition. Enhanced computational modeling ensures consistency across different material types and complex graded structures, pushing the boundaries of LENS in both manufacturing and repair applications. [7]

Q&A (FAQ)

What is the typical laser power range used in the LENS process?

Typical laser power ranges from 500 W to 4 kW, allowing for processing of a wide variety of metal powders and build sizes. [1]

How accurate are parts produced by Laser Engineering Net Shaping?

Parts manufactured via LENS typically achieve X/Y resolution accuracy of 0.002 in and Z resolution of 0.020 in under optimal settings. [2]

Which industries use LENS for repair with 3D printing applications?

Aerospace, energy (including turbines), medical implant, tooling, and defense industries all use LENS for the repair and refurbishment of high-value components. [8]

How do high cooling rates affect microstructure in LENS?

High cooling rates—ranging from 10² to over 5,000 K/s—enable the formation of refined, directionally solidified microstructures, which enhance mechanical properties and allow for control over grain size and phase distribution. [5][7]

What are functionally graded materials (FGM) in the context of LENS?

FGM fabricated with LENS feature gradual transitions between different alloys within a single build. The technology allows precise control over the composition by adjusting powder feeds and process parameters, ideal for specialized engineering applications. [6]

How is the LENS process environment kept contaminant-free?

The LENS process takes place in a sealed chamber or local shroud, with oxygen and moisture levels maintained below 10 ppm to ensure metallurgical integrity and prevent oxidation. [6]

Sources

- Comprehensive Materials Processing — Laser Engineered Net Shaping (2014), ScienceDirect

- ScienceDirect: Laser Engineered Net Shaping — system overview and metrics (2013)

- ScienceDirect — LENS historical development, commercialization (2021)

- Wikipedia (Italian): Laser engineered net shaping, origin at Sandia NL

- JOM (1999): Fundamentals and applications of LENS

- VoxelMatters: LENS process, materials atmosphere requirements

- EngineerFix: How laser engineered net shaping works (2025)

- ScienceDirect (2017): LENS ceramics density performance — Hagedorn

- Taylor & Francis: LENS systems description