Swiss scientists are turning to 3D printing technology to address one of the world’s most pressing vision problems, corneal damage. A research team combining professionals from the Swiss Federal Laboratories for Materials Science and Technology (Empa), the University of Zurich, the Zurich Veterinary Hospital, and Radboud University in the Netherlands is working on an artificial cornea that could soon replace the need for donor tissue.

“The basis for the implant is a biocompatible hydrogel made of collagen and hyaluronic acid,” said Markus Rottmar, Head of Empa’s Biointerfaces Laboratory in St. Gallen. As these two substances occur organically in the human body, they are ideal building elements for a safe, transparent, and flexible implant.

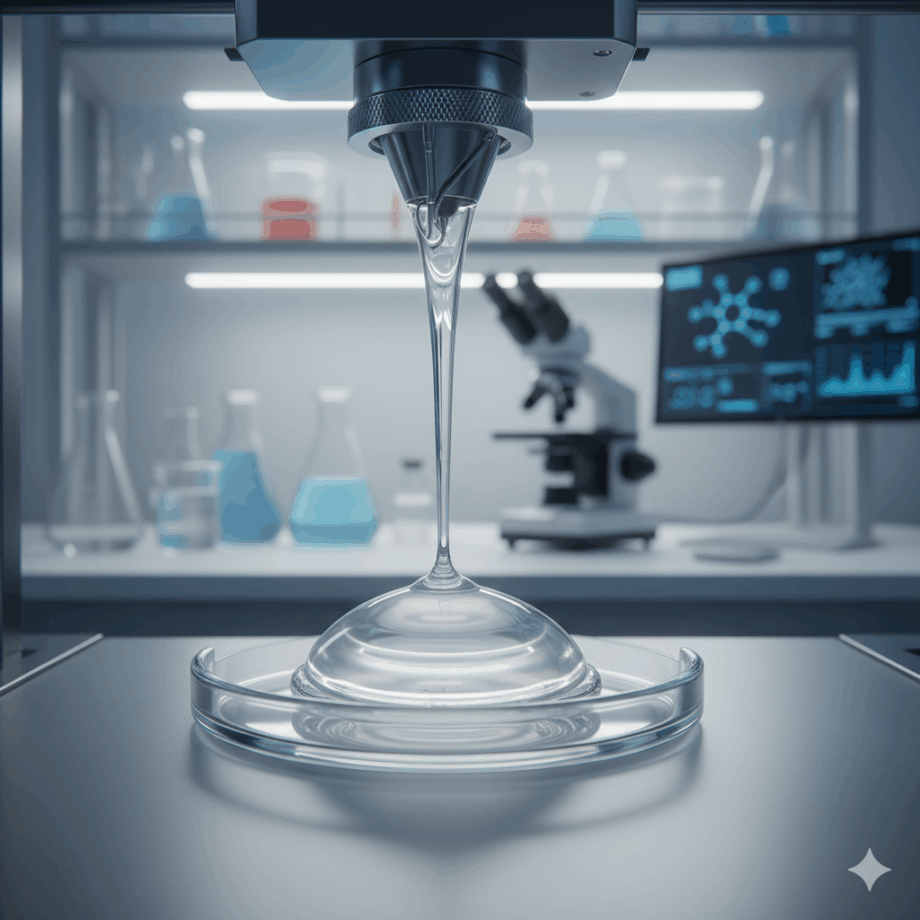

The scientists can now tailor each cornea to the precise curvature of a patient’s eye using 3D extrusion bioprinting. “3D printing makes it possible to close defects with millimeter precision – without the need for sutures,” said Rottmar. Such an approach minimizes surgical time and lowers risks of infection, scarring, and inflammation.

The team doesn’t see the 3D printed implant as just a passive replacement. They plan to incorporate stem cells from the eye to actively support tissue regeneration, which will effectively help the cornea heal itself.

Corneal damage is arguably the most widespread vision problem across the globe, with millions of patients suffering from the disease worldwide. Only about 100,000 of these patients receive transplants each year due to a shortage of donor tissue. Empa’s self-adhesive implant is on a mission to change that.

Although it has only been six weeks since the project, researchers are hopeful. “It will take several years before we reach clinical trials,” Rottmar said, “but the potential impact is enormous.” Funded by a private foundation, the project marks a new era for customized, donor-free vision repair.