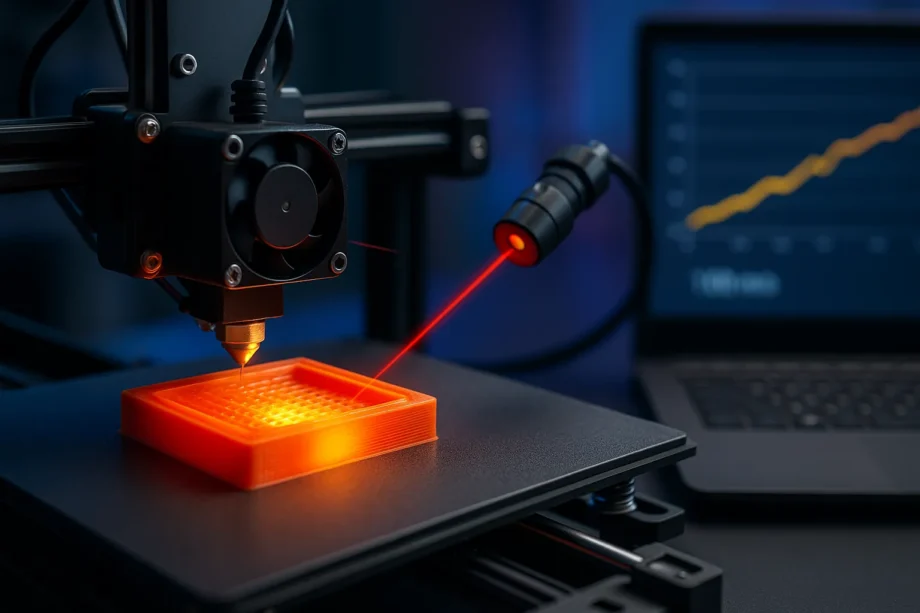

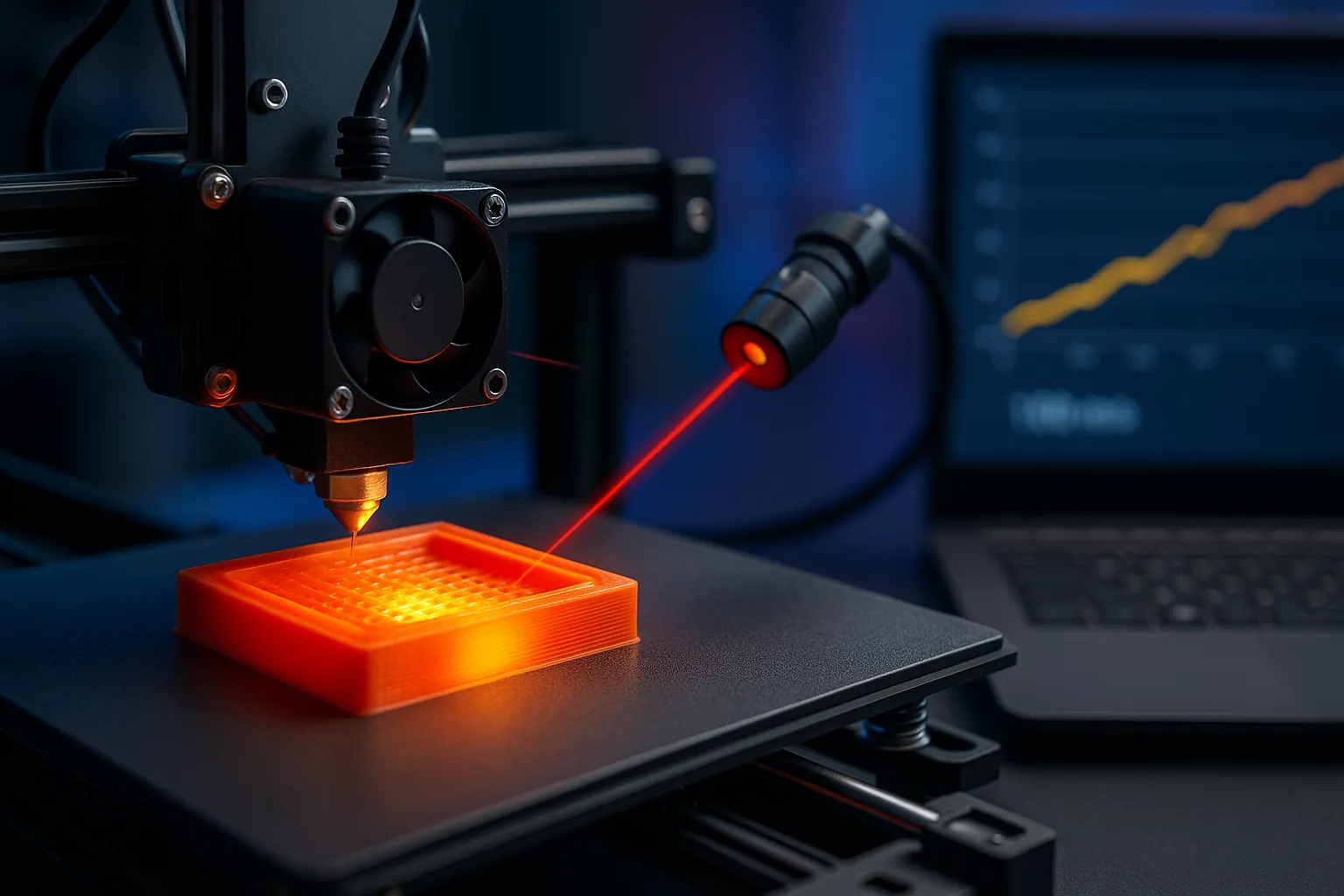

How to control the curing of thermosetting polymers has long been a tough question in direct ink write (DIW) 3D printing. In a recent study, researchers led by Edgar B. Mejia have offered a real-time monitoring and automated control system that redefines how high-performance thermosets are printed. Their research, detailed in Advanced Manufacturing, shows how sensor-driven feedback enhances the fidelity, strength, and efficiency of printed parts.

“Thermosets are indispensable for industries like aerospace, automotive, and biomedical fields,” stated the scientists in their article, “but their rapid, exothermic polymerization often leads to uneven curing and defects.” Conventional methods have failed to adjust during printing, while the new system changes that completely.

By combining infrared thermography and optical sensors, the team tracked temperature changes and shifts in material translucency, which serve as direct indicators of the polymerization front. These data streams fed into a closed-loop control system, automatically fine-tuning extrusion rate, deposition temperature, and print speed. “By maintaining the polymerization front within a desired window, we mitigated common issues like voids, warping, or incomplete curing,” the research team explained.

Machine learning adds another dimension: trained on diverse polymerization profiles, the system predicts how reactions unfold under changing conditions and adjusts parameters in real time. This results in smoother prints, reduced waste, and new possibilities for complex geometries, including overhangs and lattices that were deemed unprintable.

Beyond defect control, this method has potential to enable tailored microstructures, embedding toughness, thermal conductivity, or other localized properties directly into a print. “This adaptive control opens doors to greener, more sustainable 3D printing, where efficiency and precision go hand in hand,” said Mejia.

The team demoed the system using acrylate-based thermoset inks, achieving stronger, more uniform parts than conventional curing allowed. With its modular sensor design and open-source framework, the approach can be integrated into existing 3D printers, which could mean wider industrial adoption.