MIT engineers have unveiled a novel 3D printing technique that could dramatically cut waste and enhance efficiency when producing intricate parts, from customized dental implants to sophisticated interlocking gears.

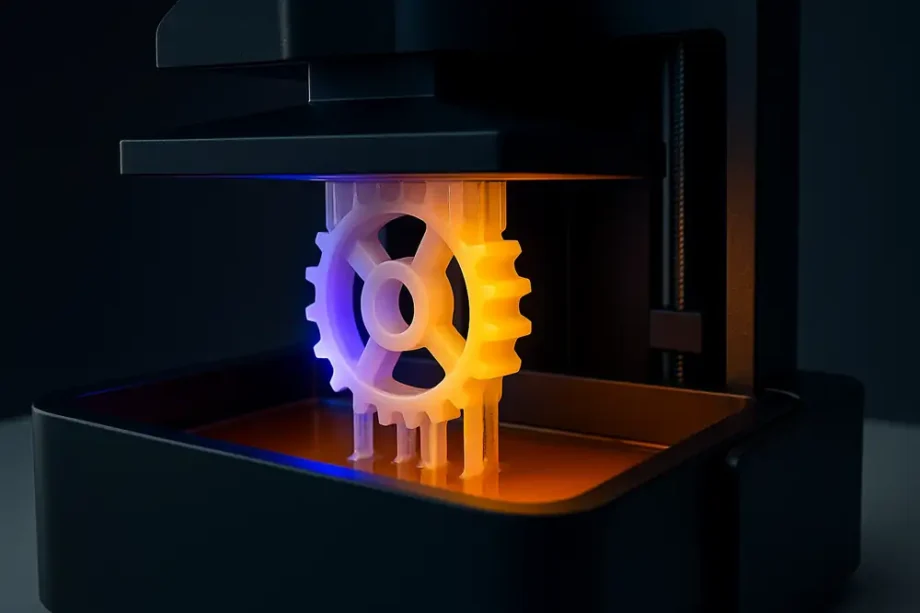

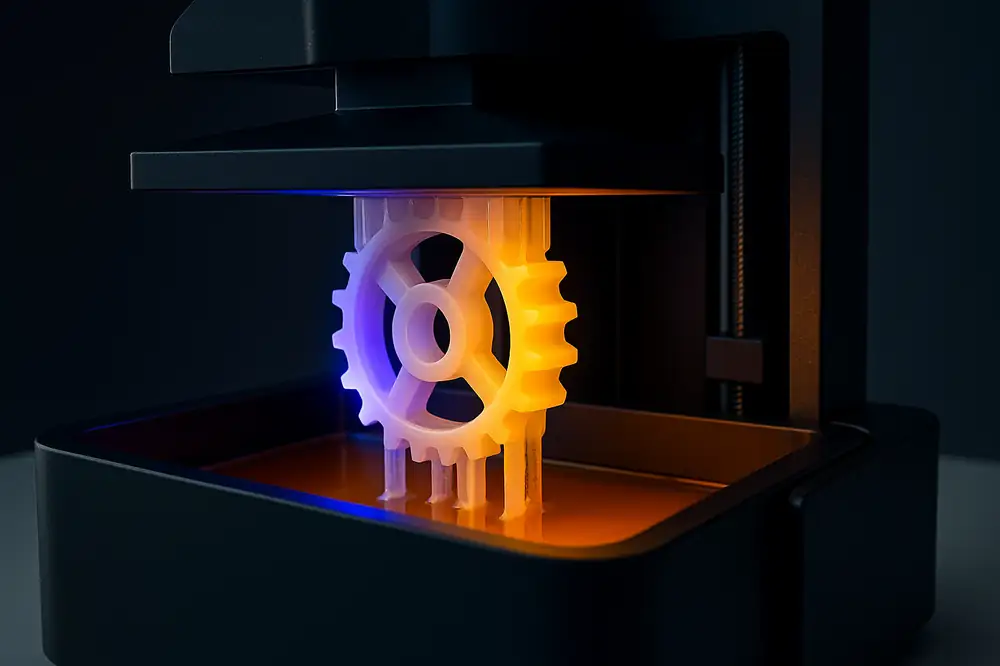

At its core, the innovation has a light-sensitive resin that hardens into two different kinds of solids depending on the light used. “Ultraviolet light cures the resin into a highly resilient solid, while visible light turns the same resin into a solid that is easily dissolvable in certain solvents,” the study‘s lead author, MIT graduate student Nicholas Diaco, told MIT News.

Conventional 3D printing requires manually removing and discarding support structures. With this groundbreaking method, however, those supports are printed using visible light and can simply be washed away in a gentle solution, even such as baby oil, leaving the final product untouched and the support material recyclable. “Instead of throwing out this material, you can recycle it on site and generate a lot less waste,” said Diaco. “That’s the ultimate hope.”

The team tested their method on functional gear trains, lattices, and even a dinosaur encased in a dissolvable egg-shaped shell. The printed parts came out perfectly intact after a quick dip in solvent.

The resin itself is a blend of two off-the-shelf monomers, with a third added to strengthen UV-cured sections. This allows the same material to perform two different roles, depending on the light source: robust structure and dissolvable support.

“We want to develop additional resins with this wavelength-selective behavior,” added Professor John Hart, co-author and head of MIT’s Department of Mechanical Engineering. “It’s an exciting path to resource-efficient and cost-effective polymer 3D printing at scale.”