Nike has started a brand new chapter in sneaker design with the launch of the Air Max 95000, an entirely 3D printed silhouette that the company unveiled at ComplexCon. This release is a breakthrough for Nike, which has been on a long-running journey to combine athlete performance with radical innovation in manufacturing and customization.

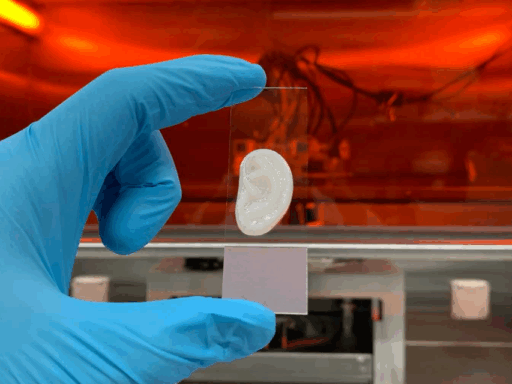

Drawing inspiration from the iconic Air Max 95, the Air Max 95000 keeps the familiar DNA yet introduces a futuristic form, enabled with Nike’s new Project Nectar printing process. This proprietary method helped create a sculptural upper with intricate detailing and enhanced durability, paired with an outsole designed for traction and daily wear. The result? A sneaker that seamlessly blends modern aesthetics with high-function performance.

“Nike Air has always been about pushing boundaries and inspiring the next generation,” Brittany Shelton, VP of North America Brand Management, said in a press release. “The Air Max 95000 brings that inspiration to life through innovation that delivers creativity and opportunities for self-expression.”

The Air Max 95000 is also the second sneaker Nike has developed in collaboration with Zellerfeld, a leader in experimental 3D-printed footwear. Their partnership is a great showcase of how computational design and additive manufacturing boost production speed and expand possibilities for personalization and sustainable prototyping.

“Zellerfeld was founded to reimagine how footwear is created and experienced,” said Cornelius Schmitt, CEO of Zellerfeld. “Nike has always defined the future of footwear, and Zellerfeld’s technology is helping unlock new possibilities in design.”

The silhouette retains Nike’s signature “Big Bubble” Max Air unit in the heel and a smaller forefoot unit for a consistently springy, ultra-responsive feel underfoot.

The Nike Air Max 95000 is available on November 28 in a Black/Volt colorway on SNKRS and zellerfeld.com.