A new record in 3D printing has just been set in the automotive industry. MacLean-Fogg Company (MFC) and Fraunhofer Institute for Laser Technology ILT have produced nearly solid die casting tooling insert for Toyota Europe’s Yaris hybrid transmission housing.

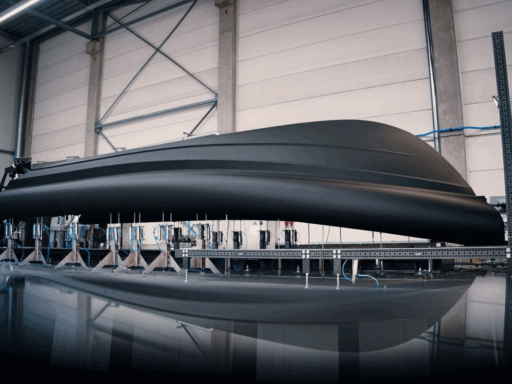

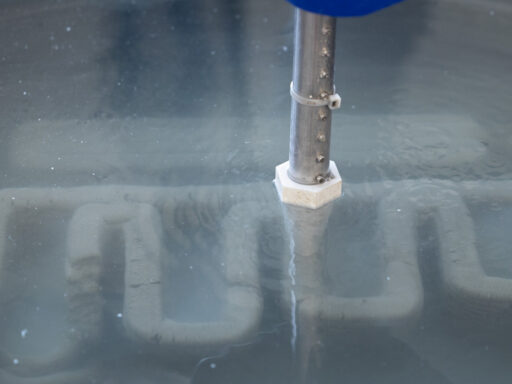

Printed using Fraunhofer ILT’s gantry-type, multi-laser Laser Powder Bed Fusion (LPBF) machine and MacLean-Fogg’s patented L-40 tool steel powder, the insert is the world’s largest insert at 156 kilograms. To meet Toyota’s cost and performance requirements, the team used a hybrid manufacturing process.

“Gantry printing with L-40 tool steel powder material, a promising avenue towards scalable additive manufacturing, is opening the potential for metal 3D printing to reduce lead times and to realize more responsive manufacturing,” Toyota Europe’s Dr. Magdalena Coventry and Dr. Andrew Willett said in a press release. “We are thrilled to be at the forefront of innovations in the rapidly developing universe of additive manufacturing.”

L-40 powder was specially engineered to offer high hardness and toughness while reducing crack formation at lower pre-heat temperatures. Unlike traditional tool steels, it minimizes the need for time-consuming heat treatments, makes insert lifespan twice longer, lowers maintenance, and enhances sustainability by reducing cobalt and nickel content.

“Toyota posed a thrilling challenge by requesting to expand the application of L-40 to large-format tooling inserts,” said Dr. Harald Lemke, Director of Product Development at MacLean-Fogg. “We had to overcome scale-up challenges such as ensuring consistent gas flow conditions as build sizes grew.”

Fraunhofer ILT tackled those challenges with its gantry-type LPBF platform that can produce parts longer than 50 centimeters at chamber temperatures up to 200°C. “This was precisely our motivating factor to develop the gantry system,” said Dr. Niklas Prätzsch of Fraunhofer ILT.

MacLean-Fogg will present their innovation at Formnext 2025 in Frankfurt this November.