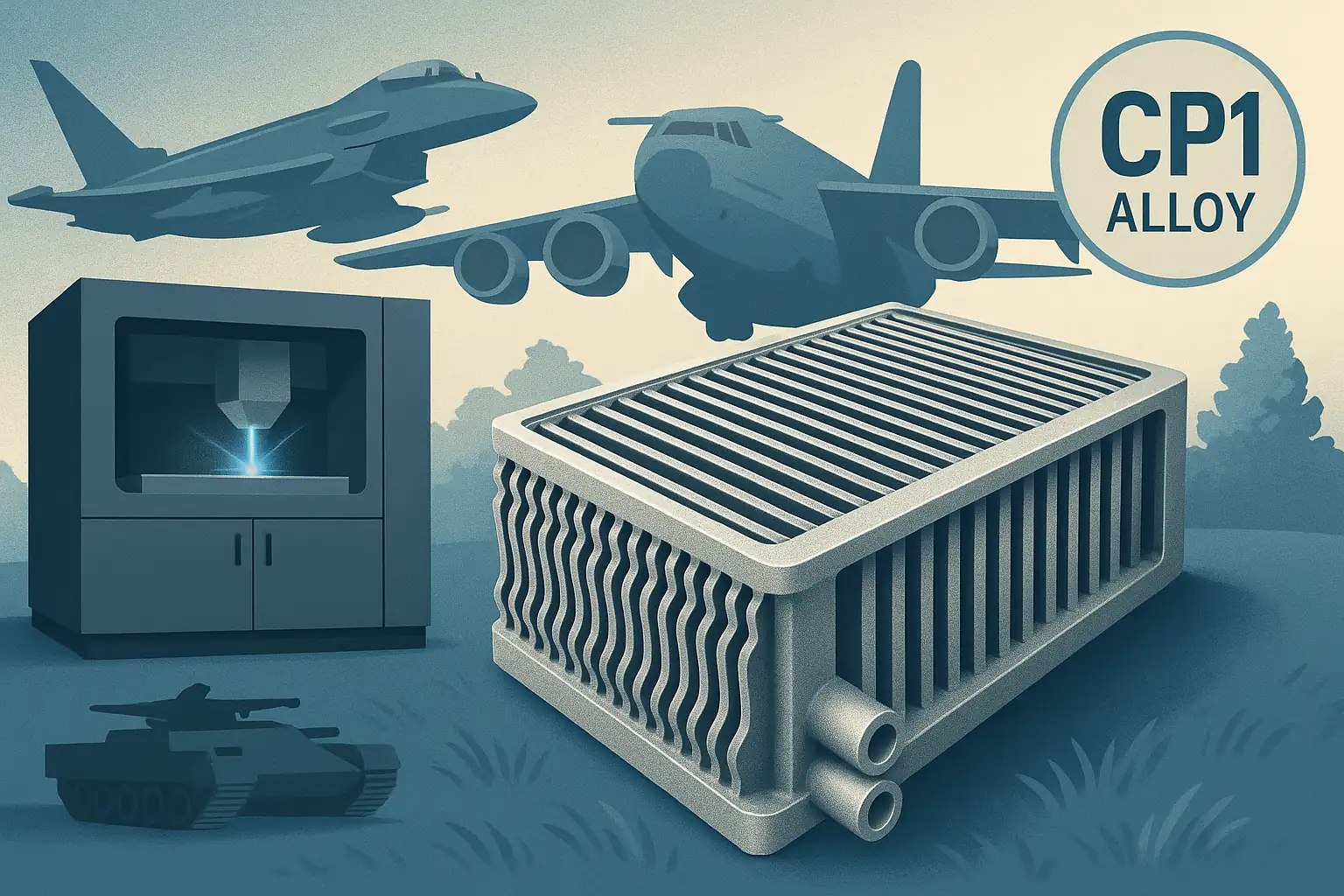

Nikon Advanced Manufacturing has entered a strategic development agreement with the National Center for Defense Manufacturing and Machining (NCDMM), which manages America Makes, to create a comprehensive dataset for Constellium’s Aheadd® CP1 aluminum alloy. This $2.1 million initiative, funded by the Office of the Under Secretary of Defense’s Manufacturing Technology Office (OSD ManTech), aims to fast-track the integration of additive manufacturing (AM) in defense and aerospace.

The partnership will utilize Nikon SLM Solutions’ large-format NXG XII 600 series laser powder bed fusion (L-PBF) system to develop and validate CP1 alloy data through Nikon AM Synergy. The initiative targets thermal management and heat exchanger components, which are critical parts in aerospace and defense, where CP1 aluminum offers high-performance potential.

“We are committed to accelerating and scaling metal additive manufacturing for defense and aerospace applications,” said Hamid Zarringhalam, CEO of Nikon Advanced Manufacturing. “Manufacturers recognize AM’s tremendous potential to address gaps in the defense industrial base.”

The program’s initial stages focus on generating basic and intermediate-level property data for CP1, with supervision from a Government Advisory Team formed in collaboration with the Joint Additive Manufacturing Working Group (JAMWG). The validated dataset will be transferred to the Department of Defense’s Workbench for Additive Materials (WAM), facilitating broader industry access.

“This project focuses on basic and intermediate-level property characterization… to guide the Material Property Dataset transfer into the WAM database,” said Dr. Behrang Poorganji, vice president of technology at Nikon Advanced Manufacturing, said in a statement.

The initiative has been supported by theleading defense contractors, such as Lockheed Martin, Northrop Grumman, RTX, General Atomics, and Honeywell Aerospace Technologies – these companies will provide technical guidance and integration forecasts. According to internal projections, defense OEMs expect a significant return on investment compared to legacy alloy-process combinations.