A research team at Columbia Engineering and Brookhaven National Laboratory are transforming DNA into a building material for intricate 3D nanoscale structures, inventing a new approach to nanotechnology that mimics nature’s efficiency.

“We can now build complexly prescribed 3D organizations from self-assembled nanocomponents, a kind of nanoscale version of the Empire State Building,” said Oleg Gang, professor of chemical engineering and applied physics at Columbia and leader of the Soft and Bio Nanomaterials Group at Brookhaven.

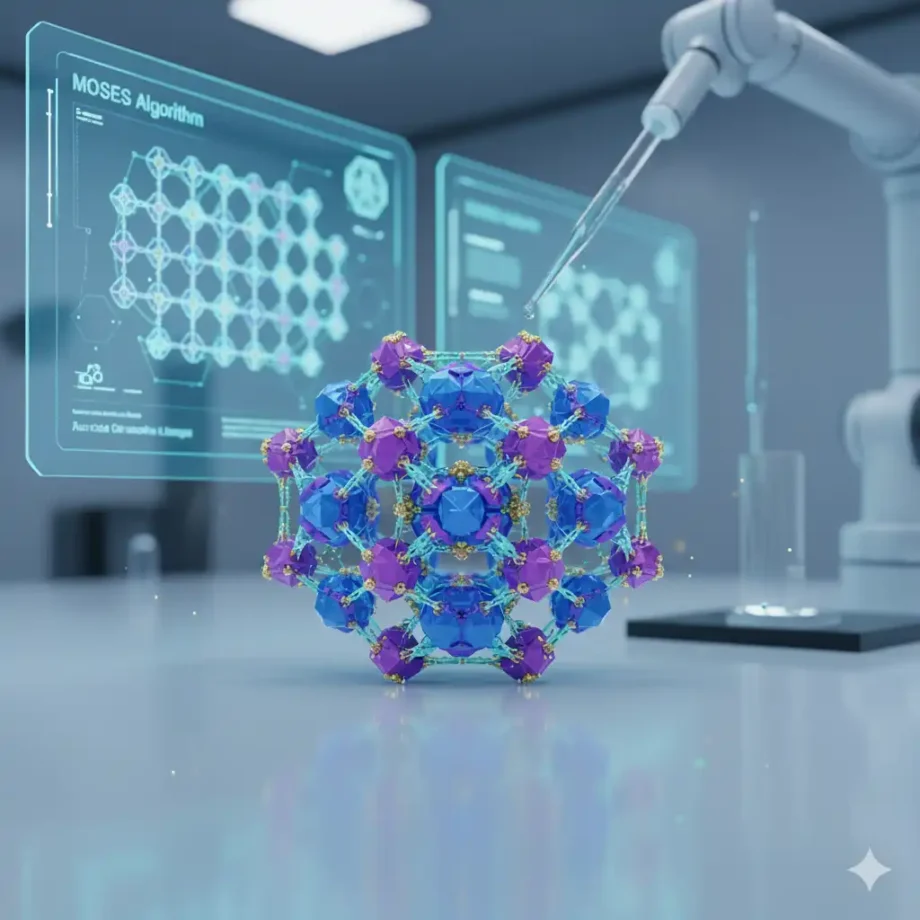

The team utilizes strands of DNA folded into octahedral “voxels,” which connect like jigsaw puzzle pieces to form hierarchically ordered lattices. The process, guided by a design algorithm called MOSES, allows scientists to plan intricate structures in advance, embedding nanoparticles or other functional materials into the DNA scaffold.

“This platform is applicable to many materials with different properties: biological, optical, electrical, magnetic. The end result simply depends on the design,” explained Gang.

Their work, published in Nature Materials and ACS Nano, showcases multiple applications, such as crystal-like structures, solar panel – mimicking lattices, and optical devices that can reflect light in specific ways. Collaborating scientists including Nanfang Yu at Columbia are studying how to use these 3D structures for next-gen optical computing.

The process is parallel and water-based, making it faster and more eco-friendly than traditional top-down lithography or serial 3D printing. As Brian Minevich, first co-author, explained, “This assembly methodology, coupled with liquid robotics automation, opens new possibilities for 3D nano-manufacturing across many fields.”

Gang’s team has also created methods to convert DNA scaffolds into inorganic forms by coating them with silica and heating them, creating robust, permanent structures. The research indicates there is a future where bottom-up DNA self-assembly could become an unconventional 3D printing platform at the nanoscale, allowing to create designs as intricate as the human brain’s connectivity.