A £700,000 government-supported initiative is about to redefine the future of shipbuilding, with 3D printing at the very heart of it. Rapid Fusion, a UK specialist in robotic additive manufacturing, has joined forces with Compute Maritime and partners including BYD Naval Architects, Siemens Digital Industries Software, and the University of Southampton on the GenDSOM project, to take part in the Clean Maritime Demonstration Competition.

The project’s ambitious mission is to use generative AI and large-scale 3D printing to minimize design cycles, enhance efficiency, and accelerate decarbonisation in maritime. As the test case for the project the team chose a crew transfer vessel (CTV), central to offshore wind operations. The hull of the ship will be optimised with hydrofoils manufactured on Rapid Fusion’s Apollo robotic 3D printing system.

“Confronted by multifaceted challenges, the maritime industry urgently requires truly evolved, smart design frameworks that balance sustainability with operational and economic viability,” Shahroz Khan, CEO of Compute Maritime, said in a press release. He argues the transformation of ship design is “no longer optional, it is a critical survival strategy.”

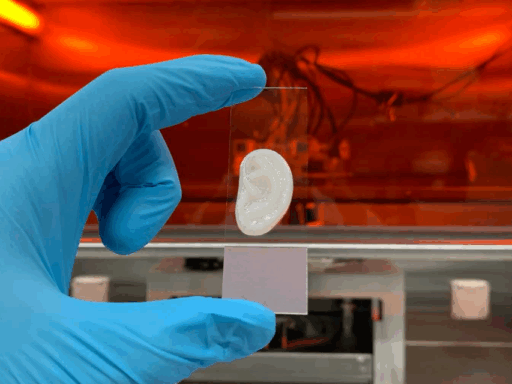

Rapid Fusion’s Apollo technology is up to 200 times faster than FDM printers, compatible with hundreds of polymers, and able to deliver big cost savings through pellet feedstock. “Additive manufacturing has expanded design freedoms and is rapidly gaining traction for both small components and large structures, including hull forms,” said Martin Jewell, CTO at Rapid Fusion.

The integration of simulation, optimisation, and real-world manufacturing constraints is what makes GenDSOM stand out. According to Siemens’ Dmitry Ponkratov, bringing all the digital elements within one loop will create a new paradigm of convergence, allowing design, performance, and manufacturability to evolve simultaneously.

The project will run over the next seven months, possibly marking a game-changing point for ship design.