Summary

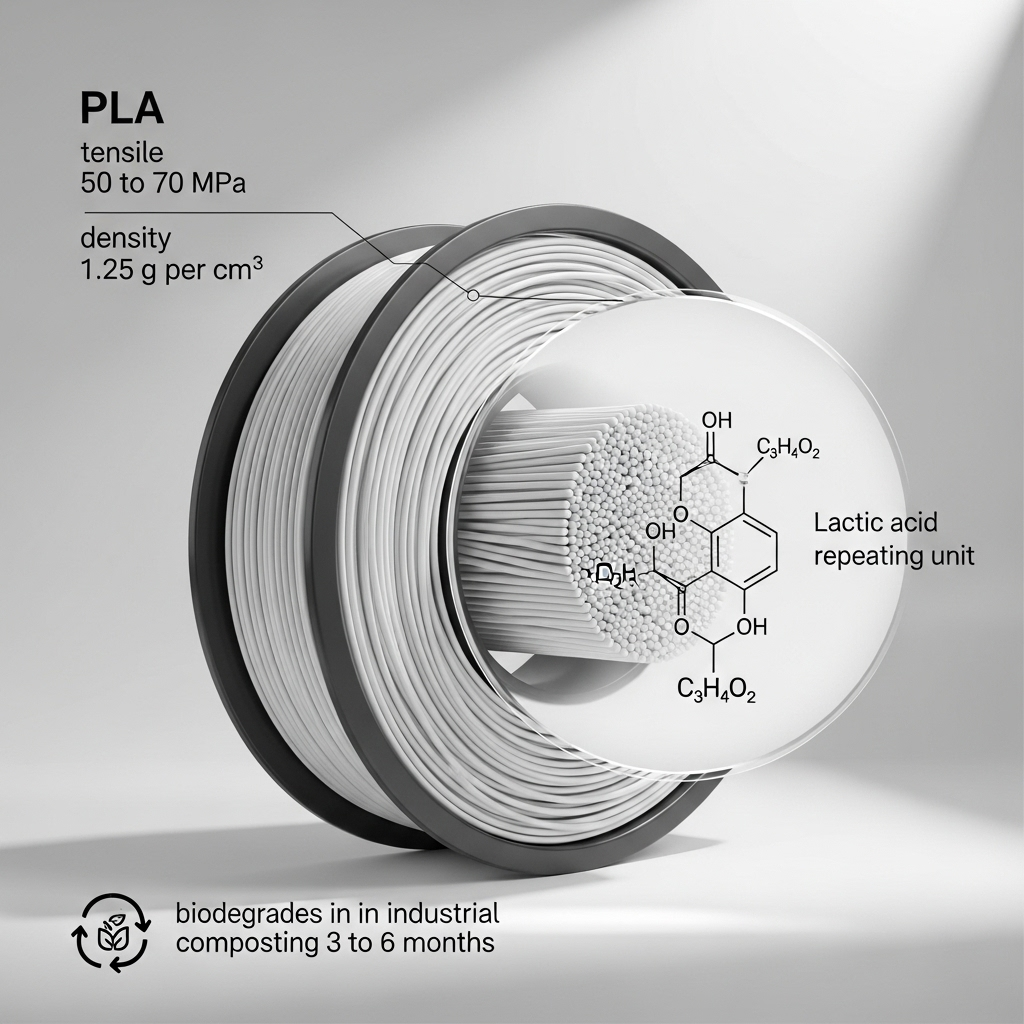

PLA filament is a biodegradable thermoplastic derived from plant sugars such as corn starch and sugarcane. It is widely used in fused deposition modeling (FDM) 3D printing because of its low melting point, user-friendly printability, moderate mechanical strength (tensile ~50–70 MPa), and convenient density around 1.25 g/cm³. Under industrial composting, PLA biodegrades within 3–6 months, making it a favored eco-friendly filament for both prototyping and packaging applications (3d2print.net, niltech3d.com).

Historical Background

Polylactic acid (PLA) traces its origins to early research into renewable, plant-derived polymers targeting sustainability and reduced fossil fuel use. The first large-scale commercial production began in 2002 when the joint venture between Cargill and Dow, NatureWorks, launched its Ingeo branded PLA manufacturing facility in Blair, Nebraska. This event marked a significant milestone, enabling reliable supply chains and increased market penetration of biodegradable plastics (en.wikipedia.org—NatureWorks). Since then, global industrial and consumer demand for PLA has steadily grown due to heightened emphasis on environmental responsibility and advancements in processing technology.

By 2022, PLA had become the single most consumed bioplastic worldwide, accounting for approximately 26% of all bioplastic demand. This rapid rise is closely linked to the surge in consumer awareness around sustainability and the expansion of desktop 3D printing (en.wikipedia.org—Polylactic acid).

Technical Principles

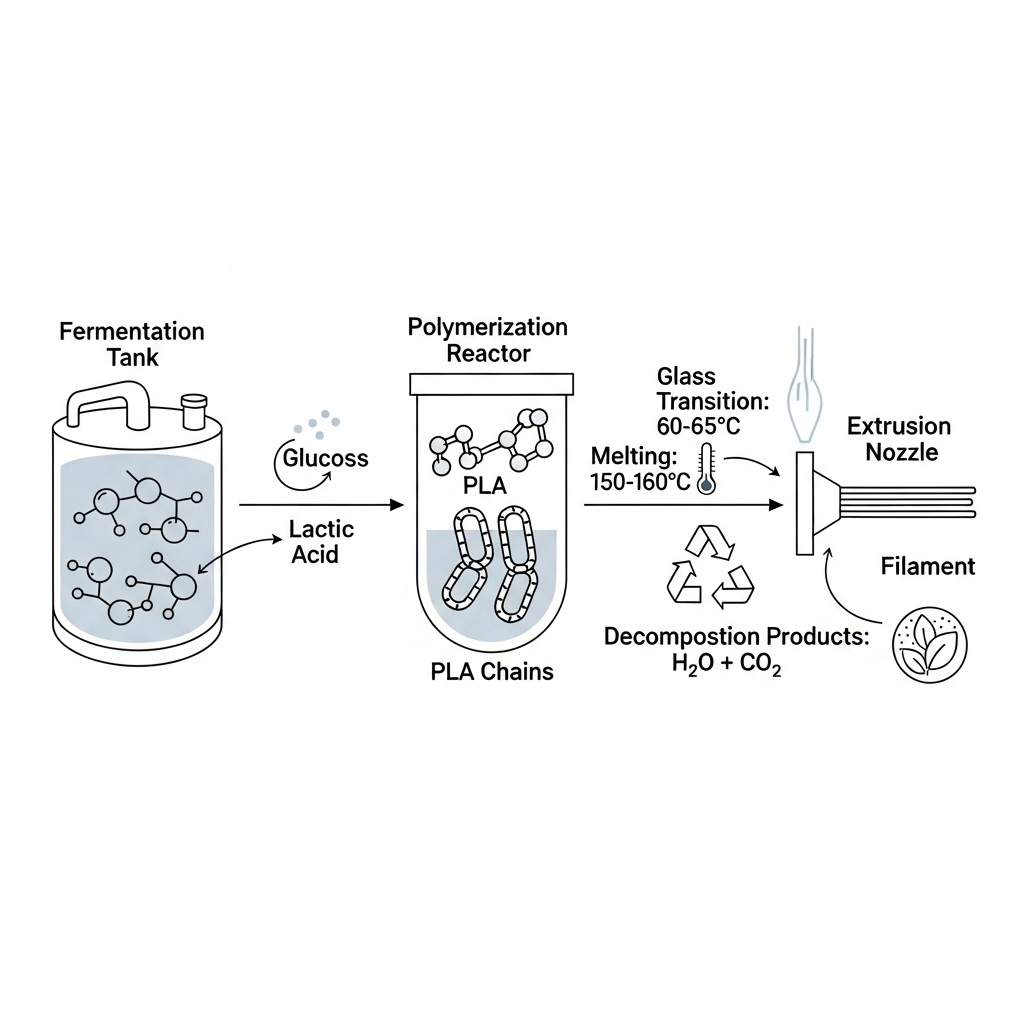

PLA is a polyester biopolymer produced by polymerizing lactic acid, itself generated via the fermentation of plant-derived sugars. The resulting polylactic acid structure offers a relatively low melting temperature, typically in the 150–160 °C range, and a glass transition temperature between 60–65 °C. This allows for easy extrusion and low-warp printing on desktop 3D printers. As a biodegradable filament, PLA decomposes into water and carbon dioxide under industrial composting conditions, making it environmentally attractive compared to conventional thermoplastics (en.wikipedia.org—Polylactic acid, 3d2print.net).

Types and Blends

Standard grades of PLA filament are defined by several core mechanical and physical properties: density typically falls at 1.25 g/cm³, with tensile strength ranging from 50 to 70 MPa, and a flexural strength measured at around 97 MPa. These values provide a balance of printability and durability for general-purpose desktop use (niltech3d.com, 3d2print.net).

Recent advances have led to new PLA blends and copolymers designed to overcome the material’s inherent heat resistance limitations. Notably, annealed blends of poly D-lactic acid (PDLA) with standard PLA greatly improve thermal properties, increasing the heat deflection temperature up to 190 °C. This innovation allows high-temperature PLA parts to maintain shape and performance under demanding operating conditions, far beyond standard grade capabilities (en.wikipedia.org—Polylactic acid).

Common types and PLA blends include:

- Standard/unmodified PLA

- PLA-PDLA annealed blends for heat resistance

- PLA composites with wood fibers, metals, or carbon fibers

- Flexible PLA blends (with TPU or PBS)

- High-impact PLA copolymers

Performance Metrics

The performance of PLA filament is characterized by a density range of 1.25–1.3 g/cm³ (niltech3d.com, divbyz.com), tensile strength values from 50 MPa up to 70 MPa depending on the formula (divbyz.com, 3d2print.net), and a flexural strength of approximately 97 MPa (niltech3d.com). PLA also exhibits a glass transition temperature around 60 °C, above which it begins to soften and lose rigidity (divbyz.com). These metrics make it suitable for light-duty and prototype parts but less desirable for applications needing prolonged high-temperature stability.

Applications

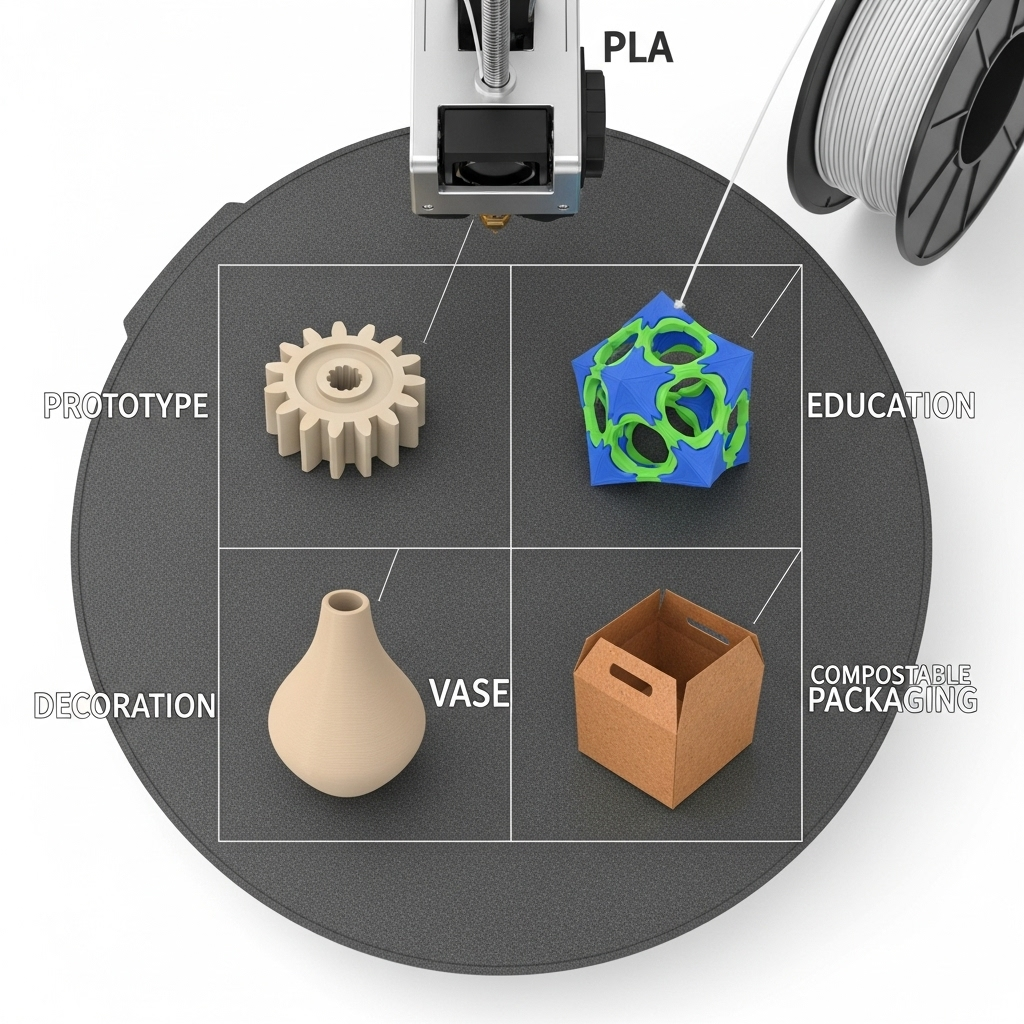

PLA filament is primarily used in FDM desktop 3D printing for prototypes, educational models, decorative objects, and compostable packaging. Its low print temperature, minimal odor, and biodegradability drive its popularity among makers and industry.

Typical applications include:

- Consumer and educational 3D prints

- Rapid prototyping for design iterations

- Sustainable packaging solutions

- Disposable medical models or test fixtures

Research Updates

Current research in PLA 3D printing focuses on optimizing the material’s heat resistance and mechanical performance. The development of new blends, such as PLA annealed by PDLA, has produced heat-resistant filaments capable of withstanding temperatures up to 190 °C (en.wikipedia.org—Polylactic acid). Efforts also target the integration of reinforcing particles (like carbon or aramid fibers) and bio-based additives. However, most mechanical property improvements stem from post-processing or blending rather than from novel base PLA formulas. No radical shifts in strength or modulus metrics have yet been reported beyond what PDLA annealing or fiber blending delivers.

Note: A detailed comparison table (PLA vs ABS vs PETG for density, tensile strength, heat resistance, print difficulty, and biodegradability) is recommended for context but is not included due to lack of collated figures in this fact pack.

Q&A (FAQ)

What makes PLA filament biodegradable?

PLA is a biopolymer synthesized from renewable plant sugars and can be broken down by microorganisms into water and carbon dioxide under industrial composting conditions (3d2print.net).

How strong is PLA in tensile terms?

Typical tensile strength for PLA ranges from 50 MPa to 70 MPa depending on grade and manufacturer (divbyz.com, 3d2print.net).

At what temperature does PLA soften?

PLA’s glass transition temperature, the point at which it begins to noticeably soften, is around 60 °C (divbyz.com).

What is the density of PLA?

PLA filament typically has a density between 1.25 g/cm³ and 1.3 g/cm³ (niltech3d.com, divbyz.com).

What is high‑temperature PLA and how is it achieved?

High-temperature PLA is produced by blending standard PLA with PDLA to enable crystal formation, followed by annealing. This process can raise heat resistance to as much as 190 °C (en.wikipedia.org—Polylactic acid).

How fast does PLA biodegrade under composting conditions?

In industrial composting systems, PLA can fully biodegrade within 3–6 months (3d2print.net).