3D printing is more accessible than ever. Nowadays, anyone can order a desktop 3D printer, grab some filament, download the right software and get started. But it wasn’t always this way.

Initially, the technology was relatively expensive, large, and technically complex, making it difficult for the general public to access. It has progressed in leaps and bounds over just a few short decades, thanks in large part to industry pioneers like Chuck Hull, Scott Crump, and Adrian Bowyer – the man behind the RepRap project to bring 3D printing to the masses!

But how did we get here? Let’s take a brief look at the history of 3D printing, answering the internet’s most pressing questions along the way!

Who invented 3D printing?

There are many different kinds of 3D printing technology, so it depends which one you’re talking about. Invented in 1984, the very first technology, stereolithography (SLA), relies on the hardening of liquid resin by a laser (usually UV) or projector. Material is selectively cured layer-by-layer to form solid objects with fine surfaces that feature a high level of detail.

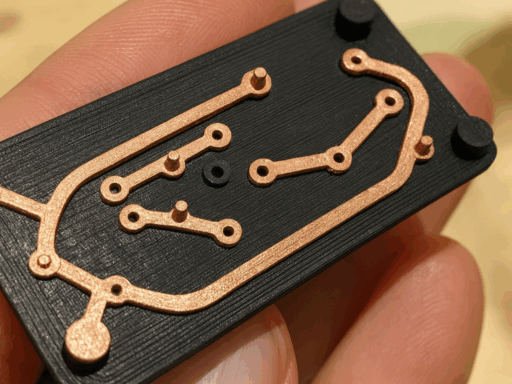

Now the most popular type of 3D printing, fused deposition modeling (FDM) was invented by Scott Crump four years later. This technique is likely more familiar to everyday readers – it involves depositing filament layer-by-layer onto a print bed, leaving behind a solid model. Mr. Crump began marketing the technology with his wife Lisa under the Stratasys name in 1989 and their company continues to address the industrial 3D printing market to this day.

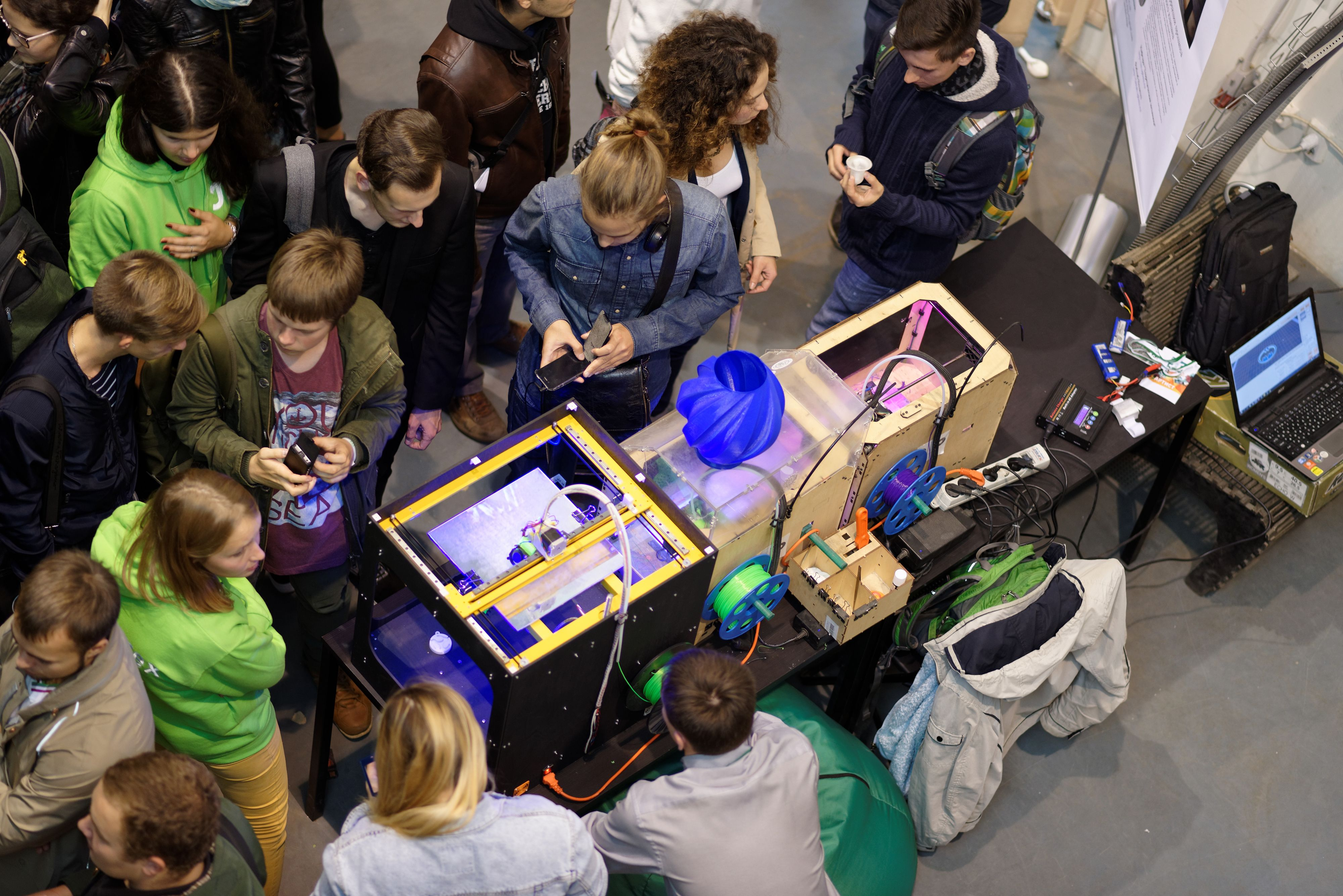

FDM hit the mainstream under a different name, fused filament fabrication (FFF), when Dr. Adrian Bowyer launched the RepRap project. The goal of the initiative was to develop a low-cost, open-source 3D printer, capable of completely replicating itself. RepRap didn’t quite manage to achieve the latter – 3D printed 3D printers still require other components.

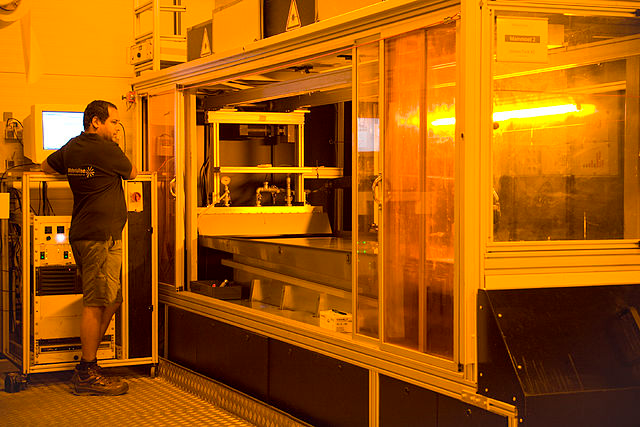

We could write a small encyclopedia breaking down all the different technologies, so we’ll keep things brief by covering some of the others in shorter fashion. Selective laser sintering (SLS) was invented by Dr. Carl Deckard at the University of Texas. Powder bed fusion (PBF), a metal printing alternative to SLS was then introduced at Fraunhofer ILT in the 1990s, around the same time as binder jetting was developed at MIT and licensed to the likes of ExOne.

More recent innovations include material jetting, which was first developed by Objet, a company acquired by Stratasys, which still markets the technology under its PolyJet brand. Again, each of these processes has their intricacies, but they’re generally more industrial-leaning. If you’d like to find out more about the latest machines on the market, check out our 3D printer guide here.

What was the first 3D printer ever made?

The first-ever 3D printer was an SLA system – as we’ve already established, this was the first 3D printing technology to hit the market. Introduced by 3D Systems in 1987, the SLA-1 may’ve been built using the same principles as modern machines, but the technology was nowhere near as advanced, and its hefty cost (approx. $200,000) priced out everyday consumers.

Nowadays, many resin systems harden material using advanced lasers or LCD projectors. By contrast, the SLA-1 relied on early gas lasers. It was also the size of a refrigerator, so the idea of desktop 3D printing would’ve sounded a bit farfetched in the 1980s!

How is Chuck Hull related to 3D printing?

For those in the know, Chuck Hull holds a very special place in the 3D printing industry. Not only did he actually invent SLA and establish 3D Systems back in the 1980s, he has played a pivotal role in the technology’s development. His firm introduced SLA to industrial users in demanding industries like aerospace & automotive – and it continues to expand its customer offering.

Hull’s contributions to the initial roll-out of 3D printing have seen him recognized with numerous awards and honors. And so he should be! Alongside innovators like FDM inventor Scott Crump, the American entrepreneur is widely regarded as “the father of 3D printing.”

Which 3D printing patents should I know about?

Patents can be a contentious topic in the world of 3D printing. All the aforementioned heavy-hitters gained their market-leading position via the commercialization of a core 3D printing technology. Some makers regard patenting such processes as obstructions to progress, in that they stop engineers from experimenting, and deploying them to their full potential.

Whatever your position on patents, it’s clear that their expiry opens the door to new players on the market. In fact, it was the expiry of the FDM & SLA patents that caused a boom in consumer 3D printing during the early 2010s. When the patents behind SLS & SLM expired, there wasn’t quite the same rise in interest, because they’re more industrial, expensive technologies.

To this day, minor patent expiries still cause ripples in the industry. A few years ago, for instance, Stratasys’ heated build chamber patent expired, creating more opportunities for competitors to develop technologies around high-temp, high-performance materials.

As you can imagine, with so much money at stake, patents can also get really contentious! Stratasys vs MakerBot is an interesting example of this – as the latter has since been acquired by Stratasys and sold on to UltiMaker. Overall, 3D printing patents are still controversial, but tracking their progress can be very helpful to understanding the history of the industry.

How is 3D printing developing over time?

This is the question on everyone’s lips – in 3D printing, anyway. The industry has suffered a lot in recent years, with many companies going to the wall amidst the challenges presented by COVID-19 and a tough wider trading environment. But this cloud does have a silver lining!

While the sales of big industrial machines have wavered in some areas due to a decline in customer spending power, desktop 3D printers remain hugely popular. All the major players from pre-COVID are still around and the likes of Bambu Lab have made huge gains. In fact, 3D Printing Industry recently reported that Bambu Lab has a 29% share of the entire consumer market. Impressive stuff for a company founded just five years ago!

As mentioned earlier, intellectual property (IP) remains a point of contention – and the company is currently engaged in its own dispute with Stratasys over patents. But the interest of everyday users is still continuing to grow and that’s a win-win for manufacturers and users alike.