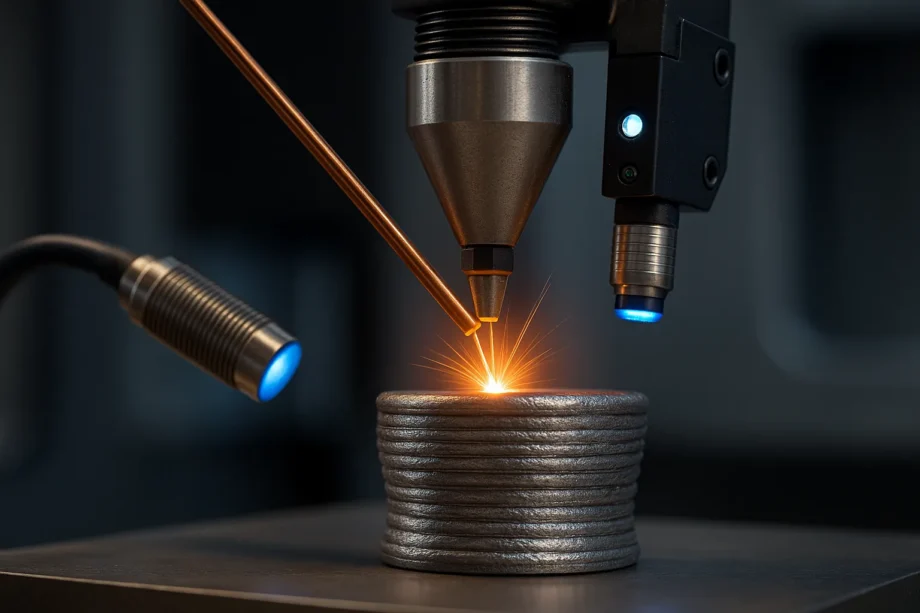

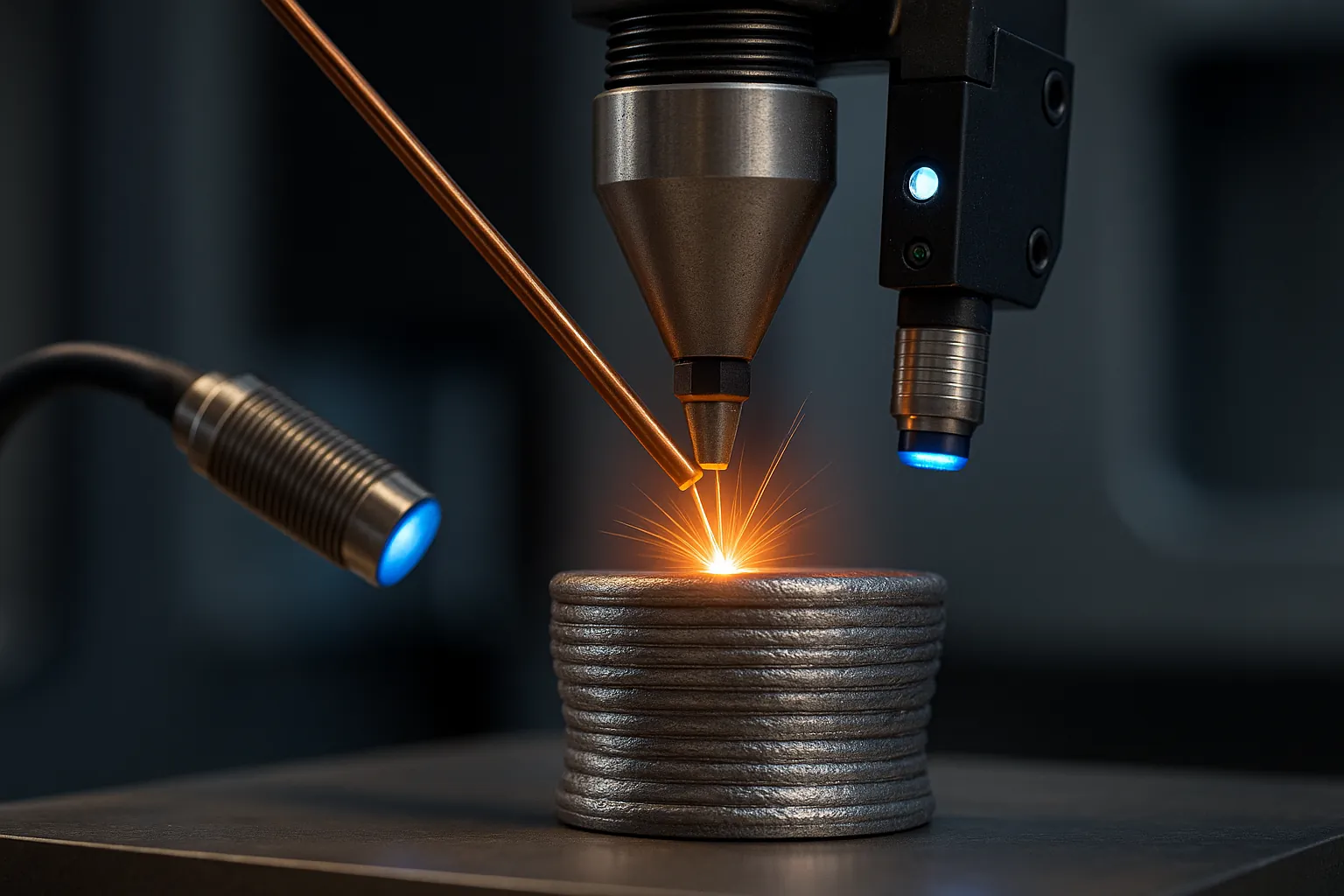

Swiss Steel Group and its French subsidiary Ugitech have revealed UGIWAM® wire, a new tailored material created for wire arc additive manufacturing (WAAM). This development is a major stride in customizing alloys for most demanding 3D printing applications, while addressing industrial need for a combination of precision and sustainability.

Unlike traditional filler metals, UGIWAM® offers custom chemical compositions, full control over raw material origins, and the benefit of 117 years of stainless steel production expertise. “The ability to adjust the composition of our products provides a major competitive advantage. We don’t just define the product; we define it for each project by considering the part’s characteristics, the customer’s manufacturing processes, and carbon footprint goals,” Marc Marticou, Director of Strategic Marketing for the Stainless Steel Division, said in a press release.

Ugitech’s research and development center is where the wire’s chemistry is constantly refined to optimize deposition properties and weldability. With dedicated systems ensuring surface stability, reducing defects, and improving precision during printing, these wires are being tested across industries from aerospace and defense to nuclear and maritime engineering.

The environmental impact is a great concern for the project. With support from the France Relance program, Ugitech is adapting its production tools for additive manufacturing while making CO₂ reduction their main priority. Customers receive the carbon footprint report of each UGIWAM® product, helping them align with a sustainable mindset.

“Additive manufacturing has established itself as a revolutionary approach in many sectors,” Marticou added. “By providing custom materials and thoughtful process optimization, we offer technology that increases efficiency while reducing production costs.”

According to CEO Frank Koch, the company’s investments in research, development, and global partnerships demonstrate their full commitment to advancing additive manufacturing while optimizing processes and helping industries of the future become more sustainable and efficient.