Researchers at Caltech have invented a revolutionary technique combining additive manufacturing with advanced materials science. Their innovation allows to create metallic alloys with unprecedented control over both shape and composition. The study, published in the journal Small, offers scientists a method to engineer metals with enhanced mechanical properties that can be used in a diverse range of applications – from aerospace to biomedicine.

At the core of this invention is a process called hydrogel-infusion additive manufacturing (HIAM), building on previous work by the Greer Lab. Initially used to 3D print single-metal microstructures, this method now allows the development of complex alloys like copper–nickel composites, precisely tuned at the atomic level. “You can actually fine-tune the chemical composition and the microstructure of metallic materials, substantially enhancing their mechanical resilience,” said Professor Julia R. Greer, who leads the lab and co-authored the study.

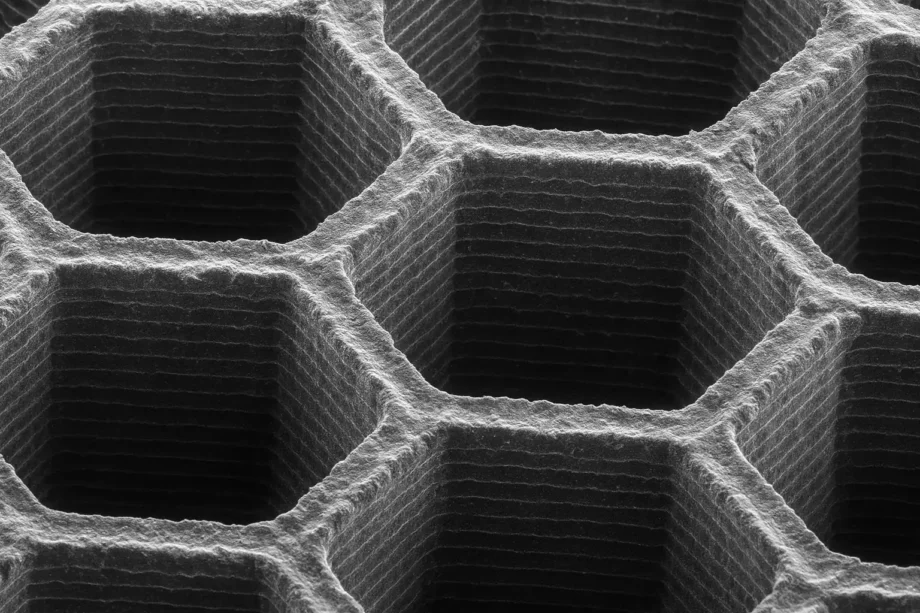

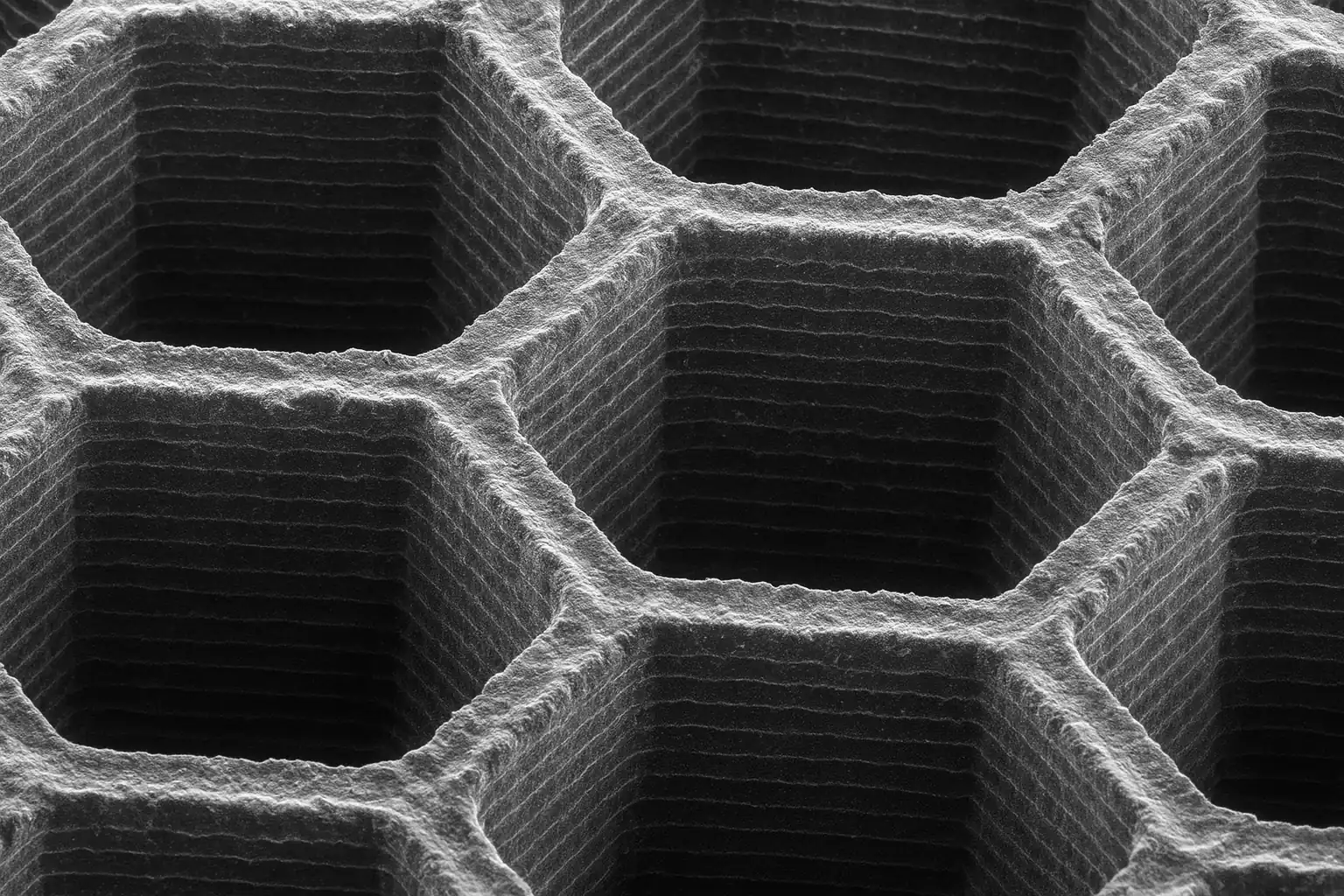

The process starts with 3D printing an organic hydrogel scaffold, then infused with metal salts, calcined to remove the organics and oxidize the metals, and subjected to reductive annealing. The latter is a process that uses hydrogen to convert oxides into a uniform metallic alloy. According to lead author Thomas T. Tran, this step is crucial for determining the alloy’s grain structure, composition, and strength.

By varying copper-to-nickel ratios, the team has shown that it is composition, and not just the grain size, that directly affects performance. One of the alloys, Cu₁₂Ni₈₈, was almost four times stronger than other variants. Transmission electron microscopy revealed nanoscale oxide inclusions that contribute significantly to this hardening effect.

“This lays the groundwork for thinking about 3D-printed alloy design in a unique way,” said co-author Rebecca Gallivan, professor at Dartmouth. “It’s bringing metallurgy into the 21st century.”