A team of bright minds at the University of Florida (UF) has stepped up to address the challenge of plastic waste the world of 3D-printing keeps facing. In this week’s Tech Tuesday for WCJB TV20, Andrew Breeden, a senior in UF’s Department of Mechanical and Aerospace Engineering, presented Simple Spool, a groundbreaking recycling solution.

This device is conceptualized and developed by Breeden and his Capstone Design team. The engineers aim to make 3D printing more eco-friendly by tackling the pressing problem of plastic waste generated during the printing process. “3D printing uses significant amounts of plastics, leading to substantial waste from failed prints. We’ve observed firsthand the large volumes of discarded material generated by student groups this semester,” explained Breeden. In addition to recognizing the tangible waste problem, engineers admitted the absence of a straightforward recycling method.

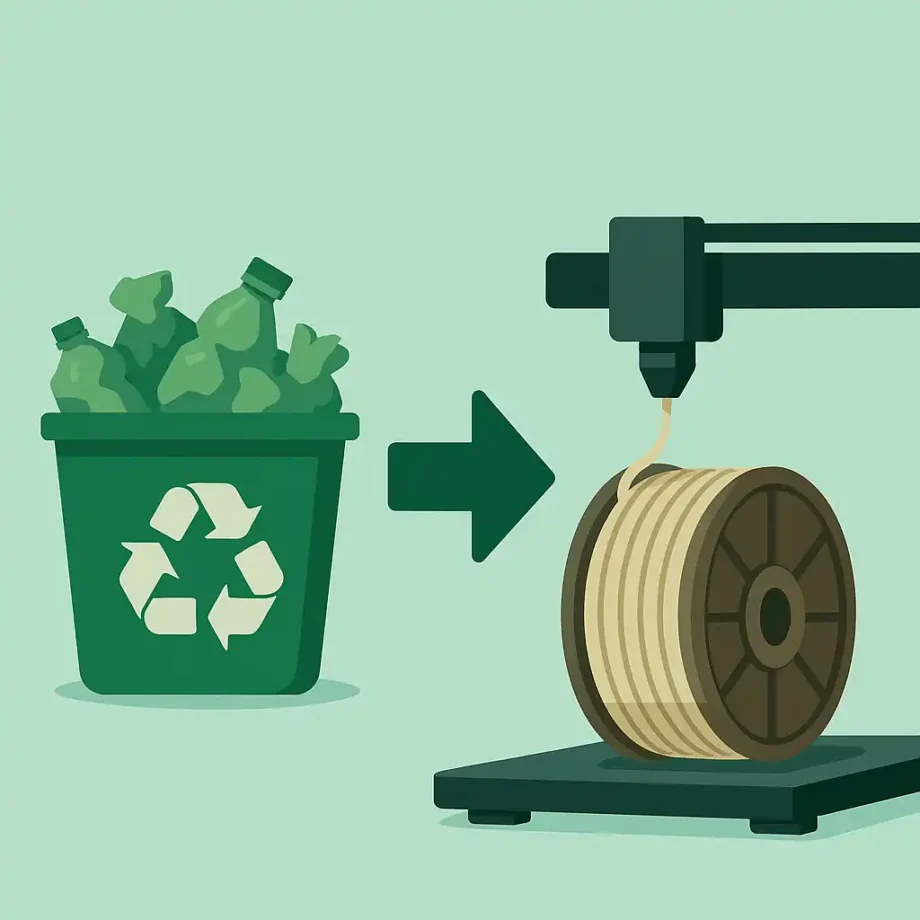

Simple Spool is built to transform ground-up recycled plastic pellets into new filament, ready to be reused in 3D printers. What sets this invention apart from other available options is its accessibility. “It’s user-friendly, easy to assemble with just a screwdriver and an Allen wrench, and designed to deliver better quality than the most basic machines on the market – all at a consumer-friendly price,” said Breeden.

The support of the University helped to bring the project to life: with the tools and environment to innovate provided by UF, engineers have been able to test and refine their invention. With full access to UF labs and expert feedback, the team was fully ready for the challenges of real-world product development.

Not only is Simple Spool a practical solution to a growing problem, it also exemplifies how student-led innovation can contribute to greener, more sustainable tech. UF’s Department of Mechanical and Aerospace Engineering is definitely a place where more creative, sustainable engineering projects will be conceived.