Summary

A desktop 3D scanner, also known as a stationary scanner for small-object scan, is a benchtop instrument designed for high-accuracy digitization of small and medium parts. These scanners typically achieve accuracy in the range of 10 µm to 0.1 mm, making them ideal for tasks in jewelry, reverse engineering, and quality control. [1][3]

Historical Background

Early desktop structured-light scanners emerged to meet the need for automated, high-precision small-part digitization in fields like jewelry and dental modeling. A notable advancement was the launch of the Artec Micro by Artec 3D (Luxembourg) in 2019, which brought metrology-grade accuracy to compact desktop devices and enabled fully automated capture of small objects for industries requiring detailed reverse engineering and artifact documentation. By integrating micro turntables and advanced optics, products like the Artec Micro have enabled professionals to scan intricate items such as gems, dental models, and micro-mechanical components with a level of detail previously restricted to costly industrial systems. [3]

Principles

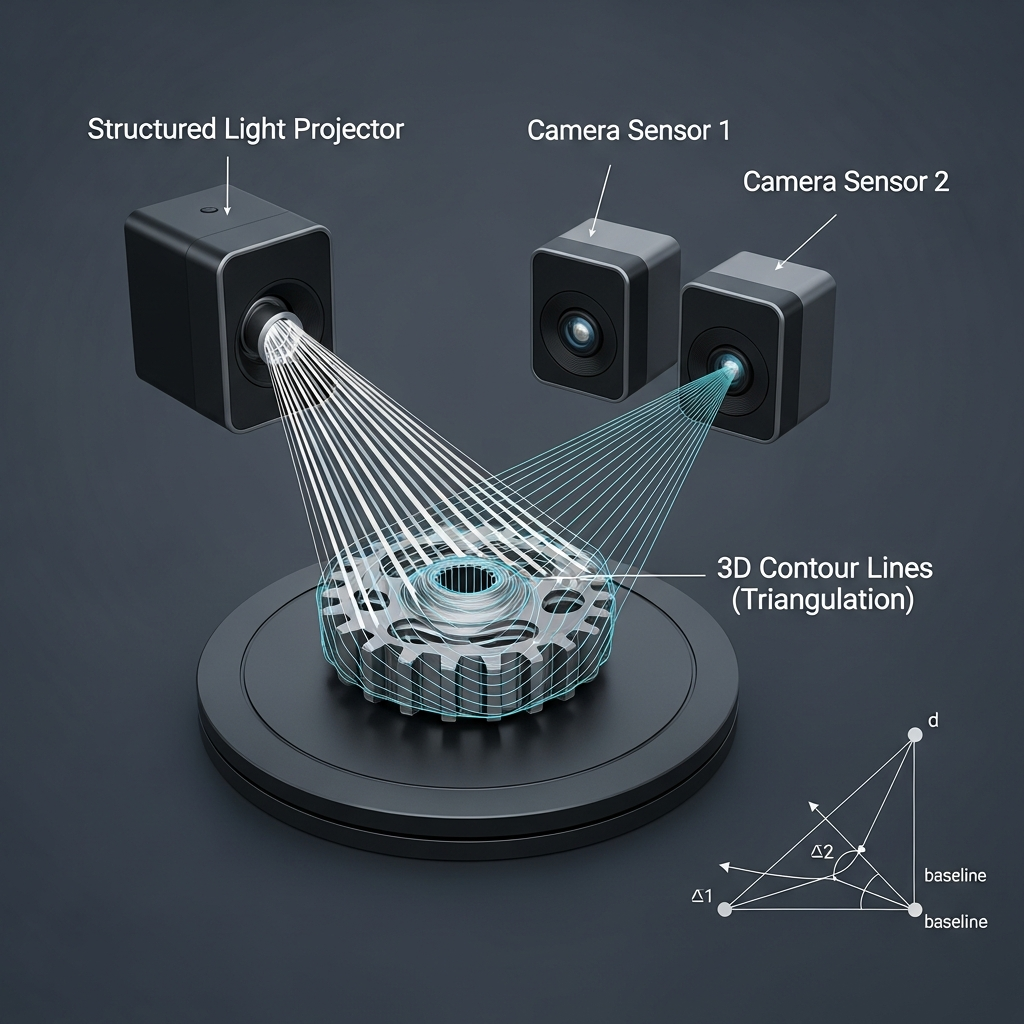

Desktop 3D scanners mainly use the structured-light triangulation method, projecting a series of coded light patterns onto an object’s surface. Sensors measure distortions in these patterns to compute 3D geometry with high spatial resolution. Two key metrics define their performance: “accuracy” (single-shot or single-frame precision — the closeness of a scan to the true surface) and “volumetric accuracy” (cumulative error over an entire object or scan session). This distinction is vital, as some systems may tout impressive per-frame numbers but accumulate more error in larger or composite scans. Understanding both measures ensures realistic expectations for real-world digitization needs. [9]

Types

Fixed-scan desktop models, such as the EinScan-SE V2, feature a stationary scanning head and a turntable. They offer accuracy of ≤0.1 mm and support object sizes from 30 × 30 × 30 mm up to 200 × 200 × 200 mm for fixed scans, and even larger volumes without the turntable. [1][2]

Automated micro turntable systems like the Artec Micro are engineered for miniature objects with up to 10 µm accuracy and scan volumes as small as 90 × 60 × 60 mm. Desktop/handheld hybrids such as the Revopoint MIRACO deliver 0.02 mm precision and 0.05 mm accuracy across a working distance of 100–1000 mm, employing both stationary and manual scanning modes. [3][5][6]

Performance

Accuracy and Precision

Desktop 3D scanners show wide variation in their specification profiles depending on intended application. The Artec Micro reaches single-scan accuracy up to 10 µm (0.010 mm) for micro-objects. The EinScan-SE V2 provides ≤0.1 mm accuracy in desktop scanning. The Revopoint MIRACO, a hybrid device, demonstrates precision at 0.02 mm and accuracy at 0.05 mm. At the higher end, the HandySCAN BLACK Elite achieves 0.025 mm single-scan accuracy and volumetric figures as tight as 0.020 mm + 0.015 mm/m (with metrology extension kit). These capabilities underpin the suitability of each model for particular metrology, design, or inspection tasks. [1][3][5][7]

| Model | Accuracy (single-scan) | Volumetric accuracy | Scan volume (mm) | Scan speed |

|---|---|---|---|---|

| EinScan-SE V2 | ≤0.1 mm | Not specified | 30×30×30 to 200×200×200 (turntable), up to 700³ (free scan) | <1 s/single shot |

| Artec Micro | 0.010 mm (10 µm) | Not specified | up to 90×60×60 | Not specified |

| Revopoint MIRACO | Precision: 0.02 mm | Accuracy: 0.05 mm | Not specified (see working distance 100–1000 mm) | 15 fps |

| HandySCAN BLACK Elite | 0.025 mm | 0.020 mm + 0.015 mm/m (with Accu+) | Not specified (small–mid size) | 1,800,000 measurements/s |

Speed and Throughput

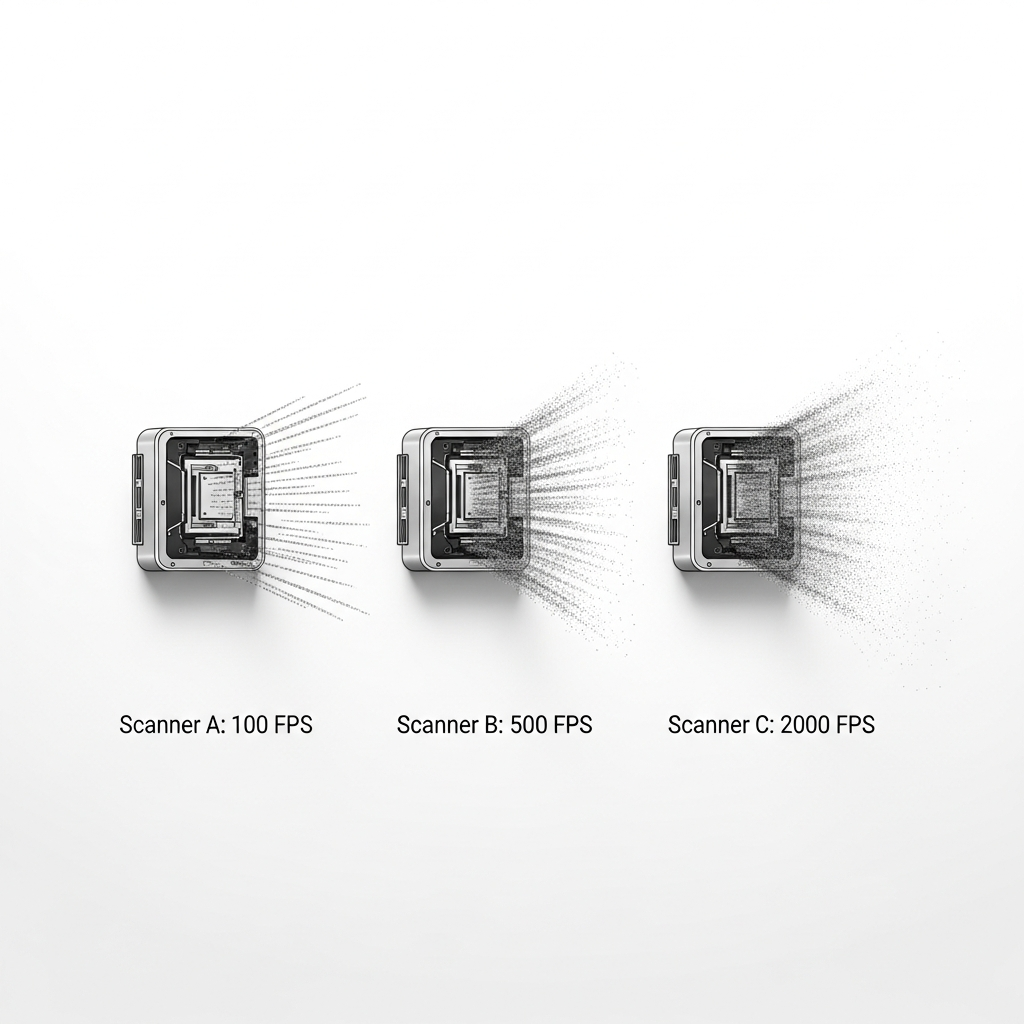

The scan speed of desktop 3D scanners plays a crucial role in their efficiency for small-part digitization. The EinScan-SE V2 captures a single scan in under one second, making it practical for multi-position or batch workflows. HandySCAN BLACK Elite delivers exceptional throughput with measurement rates up to 1,800,000 per second, supporting high-speed, high-detail captures. Meanwhile, the Revopoint MIRACO achieves a real-time capture rate of 15 frames per second, bridging desktop accuracy and in-hand maneuverability. Throughput differences impact the suitability of each scanner for production-line inspection versus single-item reverse engineering. [1][5][6][8]

Applications

Desktop 3D scanners have carved out roles across diverse professional and research domains. In jewelry design, automated turntable scanners like Artec Micro permit detailed volumetric capture for custom creation or reverse engineering. Dentistry relies on compact desktop systems for digitizing impressions and creating precise restorations. Quality control and industrial inspection benefit from scanners such as the HandySCAN BLACK Elite, ensuring manufacturing tolerances are precisely met. General-purpose desktop models like the EinScan-SE V2 are used in educational settings and for small-business prototyping. The fundamental strengths of these scanners—accuracy, ease of use, and automation—make them a mainstay in digital workflows for small-object digitization.

Applications include:

- Jewelry design and small artifact creation

- Dental modeling and prosthetics manufacturing

- Reverse engineering of miniature components

- High-accuracy inspection in quality control

Research Updates

R&D efforts in desktop high-precision scanning are rapidly advancing, with trends focusing on increased automation, better volumetric accuracy, and hybridized platforms. Systems like the MIRACO represent ongoing innovation, merging desktop precision with handheld versatility and new volumetric measurement standards, expanding the suitability for varied industrial and academic applications. [5]

FAQ

1. What is a desktop 3D scanner and how does it differ from handheld models?

A desktop 3D scanner is a stationary system designed for scanning small objects using automated turntables or fixed setups, whereas handheld models are portable and suited for larger, more complex surfaces. Desktop scanners deliver higher accuracy for small parts. [1][3]

2. How accurate is a desktop structured-light scanner for small-object scan?

Accuracy ranges from 10 µm on premium scanners such as the Artec Micro, up to 0.1 mm for standard desktop models like the EinScan-SE V2. [1][3]

3. What is desktop 3D scanner volumetric accuracy?

Volumetric accuracy refers to the total error that accumulates over the full object or batch scan and is distinct from single-frame (single-shot) precision. It is key for understanding overall measurement reliability. [9]

4. How fast are small object scans on stationary scanners?

Scan times vary: EinScan-SE V2 performs a single scan in under one second, HandySCAN BLACK Elite processes up to 1,800,000 measurements per second, and MIRACO operates at 15 frames per second. [1][5][8]

5. Expert: What factors affect the precision of a high-accuracy desktop 3D scanner?

Precision is influenced by optical quality, calibration, object surface properties, ambient conditions, and scanner design (fixed vs. handheld). Systems like Artec Micro achieve ultra-high accuracy through micro-stepping turntables and refined optics. [3][9]

6. Expert: When comparing stationary scanners like EinScan-SE V2, Artec Micro, and MIRACO, which offers better balance of accuracy, volume, and throughput?

Artec Micro leads in absolute accuracy (10 µm) but has a small scan volume. EinScan-SE V2 balances moderate accuracy (≤0.1 mm) with flexible object size, while MIRACO combines high precision (0.02 mm) and hybrid operation across variable distances. Selection depends on the required trade-off for application. [1][2][3][5]

Sources

- EinScan-SE V2 specifications – Shining 3D

- EinScan-SE V2 specifications – scan volume details

- Artec Micro details – Wikipedia

- Artec Micro product overview – Wikipedia

- Revopoint MIRACO specifications

- Revopoint MIRACO working distance

- Creaform HandySCAN BLACK Elite specifications

- Creaform HandySCAN BLACK measurement rate

- 3D scanner accuracy and resolution basics – Aniwaa