Summary

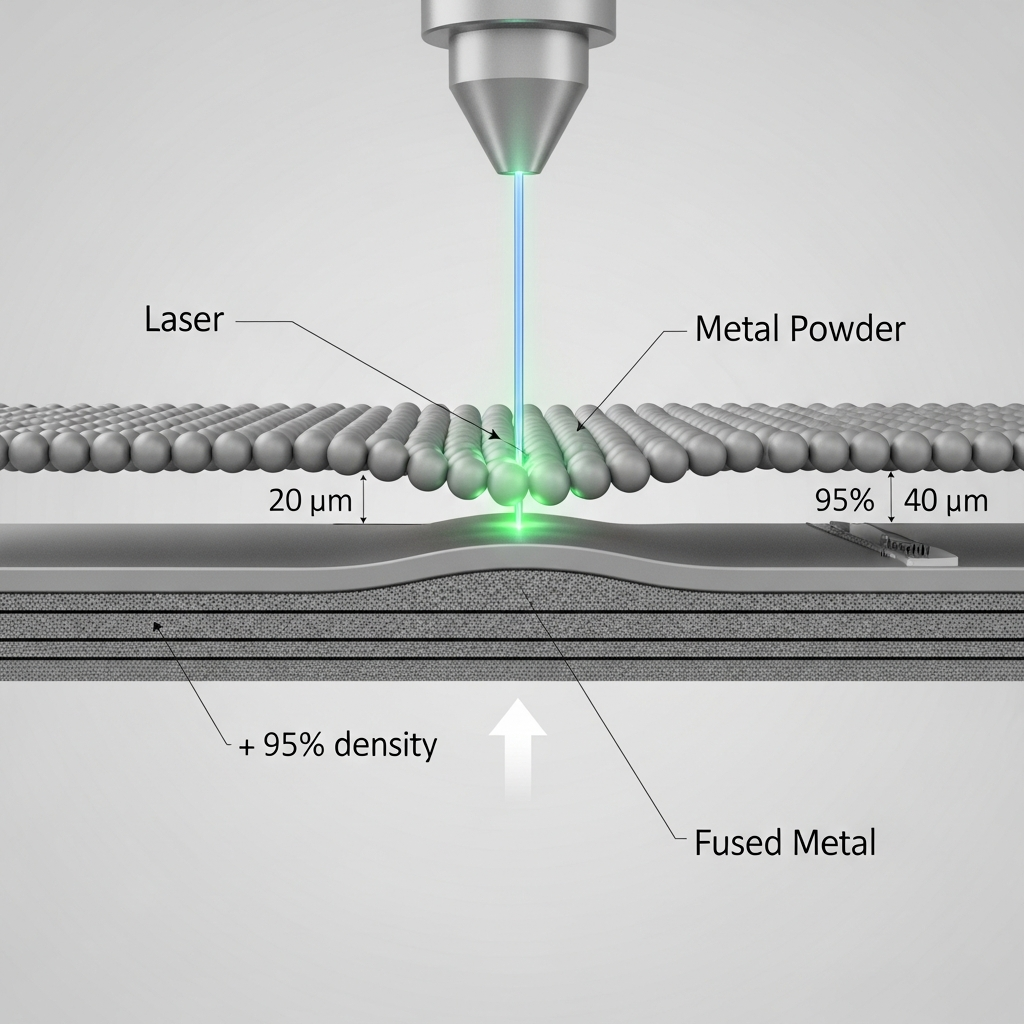

Direct Metal Laser Sintering (DMLS) is a metal 3D printing technology based on laser powder‑bed fusion, developed by Rapid Product Innovations and EOS GmbH beginning in 1994. Capable of producing highly dense, finely detailed components layer by layer from metal powders, DMLS systems achieve around 95 % part density and feature sizes as fine as 40 µm. This makes them integral for industrial prototyping, aerospace, and medical applications. [1][2][3]

Historical Background

DMLS was developed by Rapid Product Innovations (RPI) and EOS GmbH, with the first commercial EOSINT M 250 systems installed in 1995. This process built on earlier powder-based solidification patents from Pierre Ciraud (1971) and advancements in selective laser sintering by Carl Deckard in 1986. [1][2][4]

Terminological overlap with Selective Laser Melting (SLM) arose after SLM’s initiation at Fraunhofer ILT in 1995. Early experiments extended patents from Ciraud, who proposed laser powder fusion, and Deckard, who demonstrated polymer sintering, leading to metal additive manufacturing in the 1990s. While DMLS originated as a sintering process, SLM aimed for full melting, but today the terms are often used interchangeably for metal powder‑bed fusion, with distinctions largely historical. [4][10]

Principles

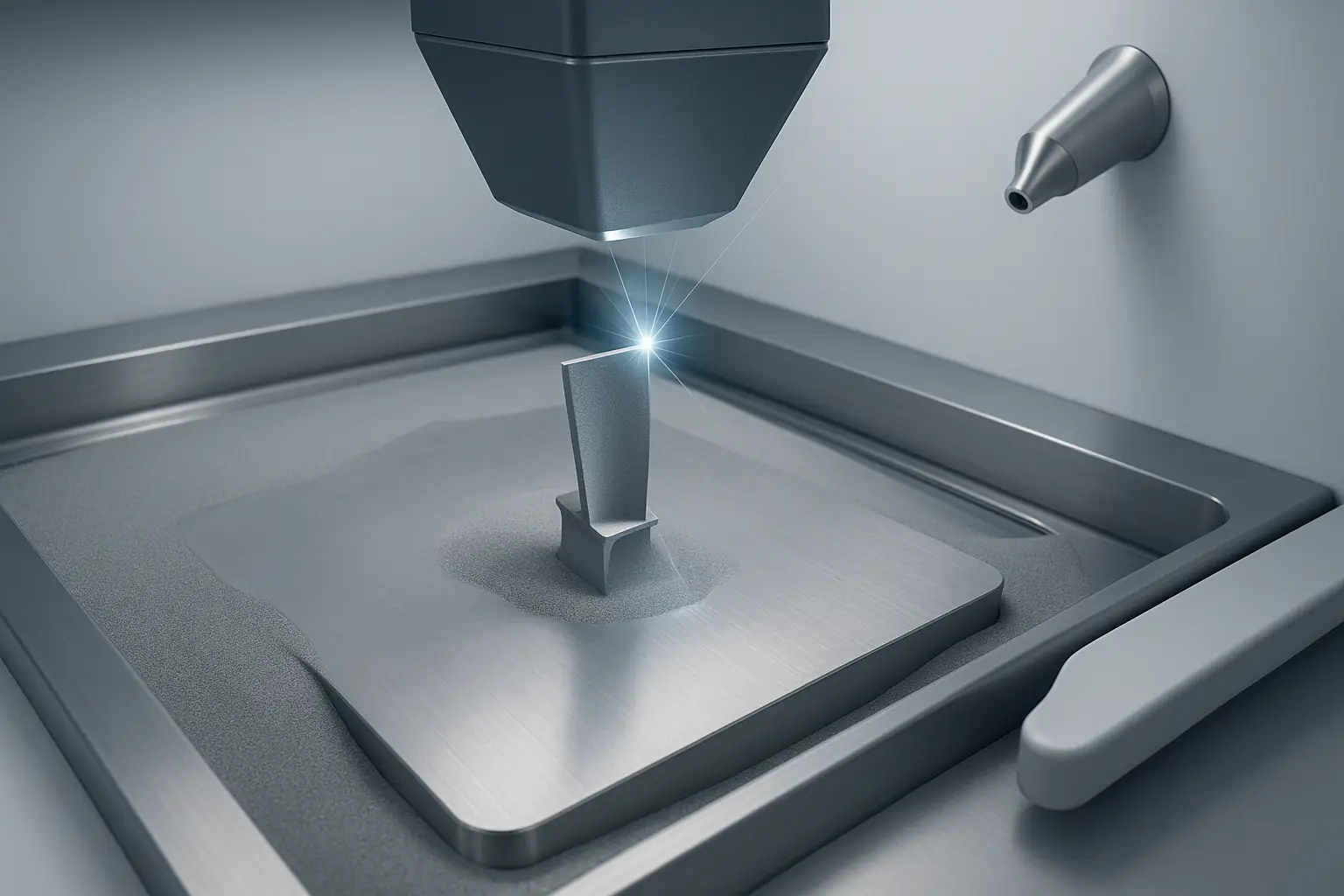

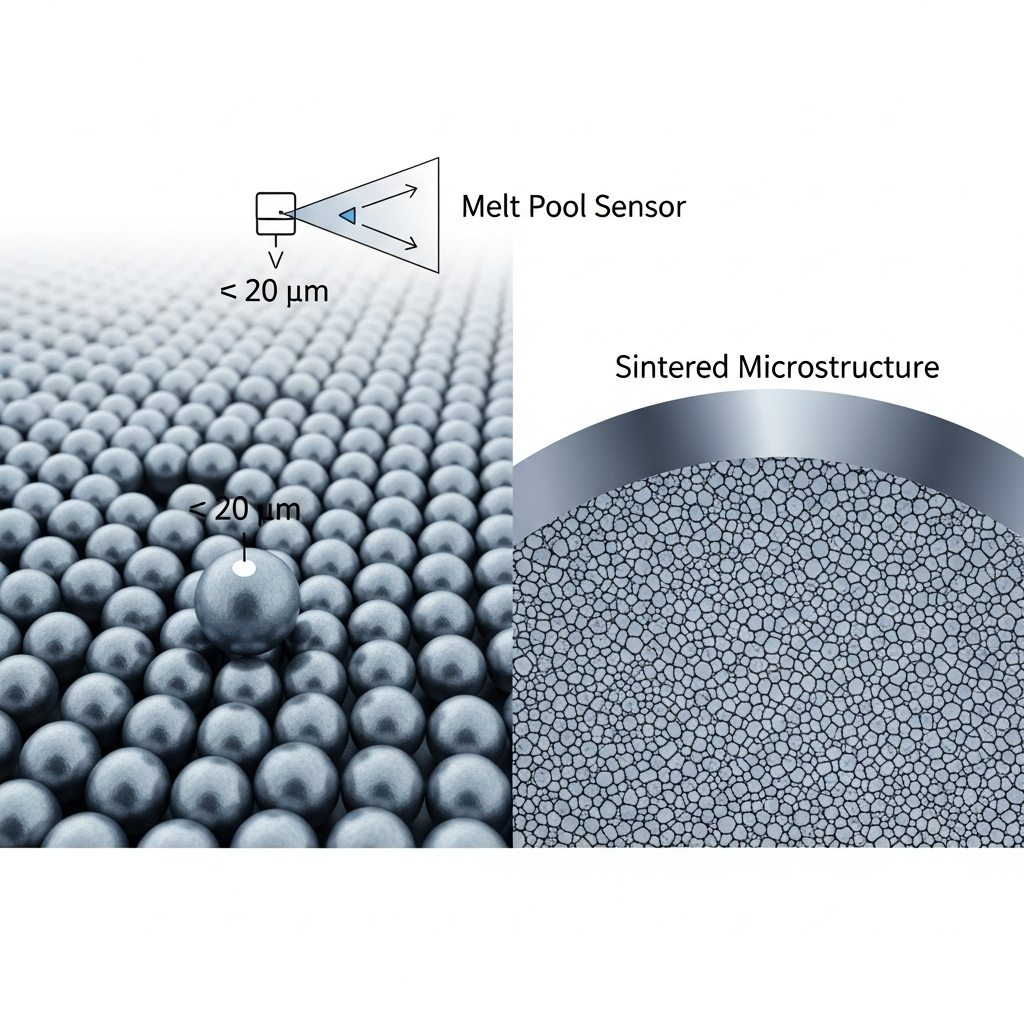

DMLS is a powder‑bed fusion process in which a focusing laser selectively melts layers of metal powder — typically measuring ~20 µm in diameter — in an inert gas environment to limit oxidation. Layers are fused sequentially, producing parts with approximately 95 % density, significantly higher than polymer SLS. DMLS systems boast scanning speeds up to 7 m/s and can resolve feature sizes between 40 and 100 µm, making them well‑suited for precision-engineered applications. Alloy steels, aluminum, cobalt-chrome, and titanium are frequent material choices. [3][5][6]

Types and Performance

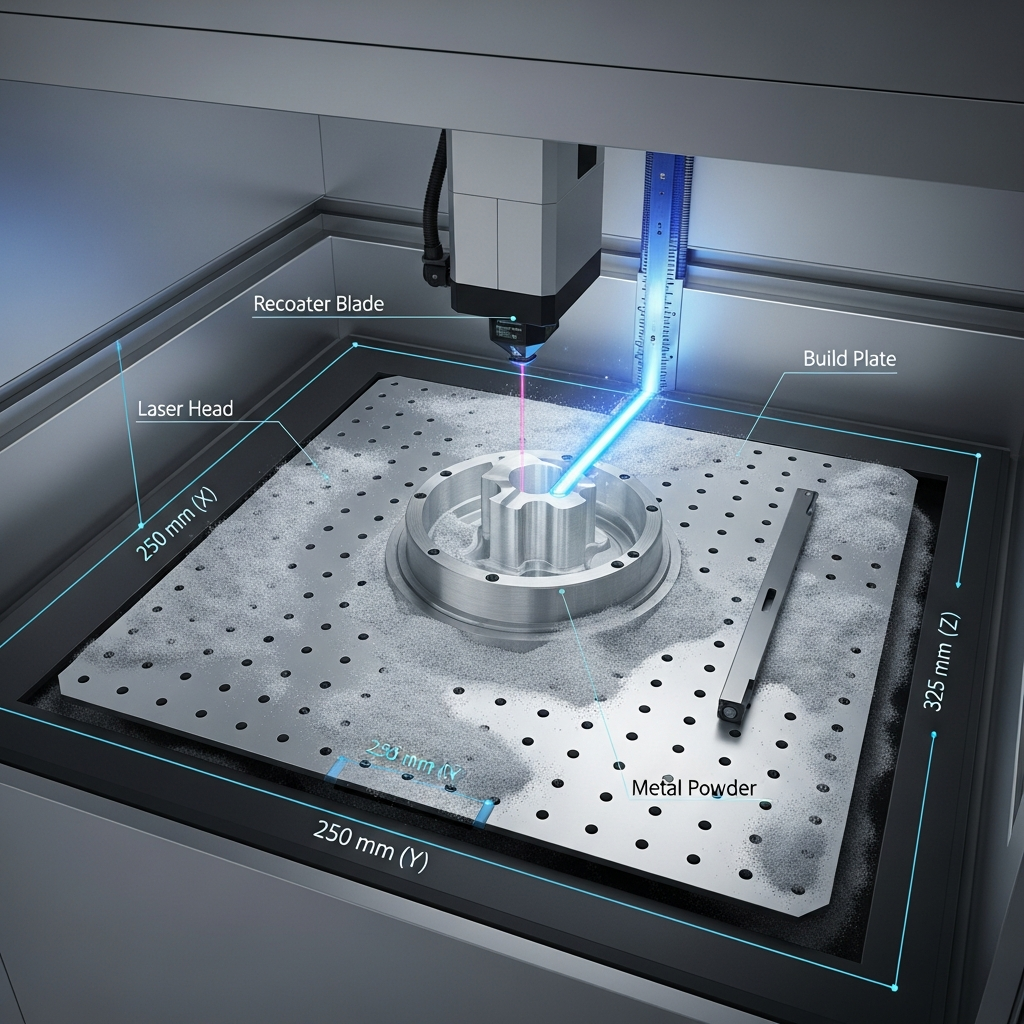

Industrial DMLS printers, such as the EOSINT M 280, offer build volumes up to 250 mm × 250 mm × 325 mm, with adjustable scan speeds reaching 7.0 m/s and focus diameters from 100 to 500 µm for feature control. These systems utilize high-power lasers (typically Yb or CO₂) and achieve rapid, precise powder‑bed scanning suitable for series production and prototyping. [4][3]

Tolerances for DMLS are typically ±0.005″ per inch initially, improving to ±0.002″ per inch for subsequent measurements; alternative sources report system minimums of ±0.15 mm or ±0.5 % of features, whichever is greater. Layer heights range from 20 to 80 µm, with recommended design tolerances of ±0.2 mm (<100 mm parts) and ±0.3 mm (<200 mm). Minimum hole/gap size is 0.5 mm, with required drain holes of at least 4 mm for powder removal. A comparison table below summarizes typical system capabilities. [7][8][9]

| System | Build Volume (mm) | Tolerance | Layer Height (µm) | Min Feature Size (µm) | Scan Speed (m/s) |

|---|---|---|---|---|---|

| EOSINT M 280 | 250×250×325 | ±0.15 mm/±0.5 % | 20–80 | 40–100 | Up to 7.0 |

| HLHfastparts | 280×280×280 | ±0.15 mm/±0.5 % | 20–80 | ~40–100 | Up to 7.0 * |

| Rapid Products | — | ±0.005″/inch | — | 40–100 | — |

* HLH scan speed not explicitly specified — typically matches EOSINT M 280 class.

Applications

DMLS enables fabrication of functional prototypes, production-grade components, conformal cooling tooling, dental and orthopedic implants, and aerospace parts. Its use in high-profile projects — such as SpaceX’s SuperDraco engine, which underwent complete DMLS-based production and was qualified for spaceflight with chamber pressures around 1,000 psi — highlights the process’ ability to achieve fine detail and high density for mission-critical applications. The medical, automotive, and industrial sectors increasingly exploit DMLS for lightweighting, mass customization, and reduced lead times. [6][11][8]

Research Updates

Recent developments target higher density, including new powders like DirectSteel H20 and advanced tool steels, as well as post-processing for improved part accuracy and surface finish. Progress in process monitoring and control continues to enhance DMLS yield and reproducibility. [2]

Academia and industry have pushed DMLS boundaries by fabricating sophisticated devices, such as metal atom dispensers for cold-atom quantum sensors and monolithic Vivaldi antenna arrays. Ongoing research reports on optimizing scan strategies to minimize defects and investigating new alloys for specialty applications, supporting the transition of DMLS from prototyping to high-reliability end-use production. [19][20]

FAQ

What is Direct Metal Laser Sintering and how does it differ from Selective Laser Melting?

Direct Metal Laser Sintering is a laser-based metal 3D printing method originating from RPI and EOS GmbH in the 1990s, using a powder-bed fusion process. Selective Laser Melting (SLM) emerged simultaneously in Germany and often describes systems aiming for complete melting. Despite technical roots, today DMLS and SLM are often used synonymously. [1][10]

What metals and powder sizes are used in DMLS metal 3D printing?

DMLS processes metal powders generally 20 µm in diameter, including alloy steels, stainless steel, tool steel, aluminum, bronze, cobalt-chrome, and titanium. The fine particle size supports excellent layer fusion and feature detail. [6]

What level of accuracy and resolution can industrial DMLS printers achieve?

Industrial DMLS printers deliver feature sizes of 40–100 µm. Tolerances range from ±0.005″ per inch (initial measurement) to ±0.15 mm or ±0.5 %, with minimum manufacturable hole/gap size at 0.5 mm. Layer resolution is typically 20–80 µm. [3][7][8][9]

How fast is the DMLS process in terms of scanning speed and build rates?

Leading DMLS machines like the EOSINT M 280 achieve scan speeds up to 7.0 m/s, balancing high throughput with precision. Build rates depend on part geometry, material, and laser power settings, best suited for dense, complex parts. [3][4]

What critical aerospace components have been produced with DMLS, such as by SpaceX?

SpaceX’s SuperDraco rocket engine is a landmark DMLS application. Fully printed using DMLS and flight-qualified, it operates with combustion chamber pressures around 1,000 psi, demonstrating the reliability of metal powder-bed fusion for high-stress aerospace environments. [11]

What is the typical part density from DMLS compared to SLS, and what process factors control it?

DMLS achieves ~95 % part density, dramatically surpassing the ~70 % of polymer-based Selective Laser Sintering (SLS). Factors influencing density include powder morphology, scan strategy, laser power, and ambient gas control. [5]

How do layer thickness, powder diameter, and laser focus influence feature resolution and tolerance in DMLS?

Thinner layers (20–80 µm), finer powders (~20 µm), and precise laser focus (down to 40 µm) enhance resolution and tolerance by ensuring complete fusion and reducing edge roughness. Smaller holes or gaps (<0.5 mm) are limited by these parameters, defining design minimums. [3][9]

Sources

- Mindware Technologies: “Direct Metal Laser Sintering (DMLS)”

- Scribd — Direct Metal Laser Sintering (DMLS) history PDF

- Xometry: DMLS Metal 3D Printing Services

- China DMLS (EOSINT M 280) datasheet

- ScienceDirect: Powder Bed Fusion Additive Manufacturing Overview

- ScienceDirect: Materials for DMLS Metal AM

- Rapid Product Solutions — DMLS Capabilities

- HLHfastparts — DMLS Service Guide

- Forge Labs: DMLS Design Guidelines

- Wikipedia — Selective Laser Melting

- Wikipedia — SpaceX SuperDraco

- arXiv: Monolithic Vivaldi antenna arrays by DMLS

- arXiv: Metal atom dispensers for quantum sensors — DMLS application