Summary

A handheld 3D scanner is a portable device designed to capture the three-dimensional geometry of objects by moving the scanner around them. These scanners are valued for their blend of high accuracy—often reaching sub-0.1 mm—and mobility, enabling detailed digital capture of complex shapes in industrial, medical, and field environments. [1][2][3]

Historical Background

The commercial origin of handheld 3D scanners traces back to the ZScanner 700, released by Z Corporation in 2006. This device achieved an accuracy of ±0.05 mm and was among the first truly self-positioning portable scanners. [4]

During the early 2010s, handheld 3D scanning technology advanced rapidly. Notably, in 2011, Artec developed a scanner capable of capturing 500,000 surface points per second—demonstrating its capabilities in both medical (custom lingerie fitting) and archaeology. The early 2010s witnessed significant progress, as firms like Artec launched compact, structured-light models while advancing real-time 3D data fusion. Subsequent generations, including the Artec Eva (2012), Spider II (2013), and Leo (2022), set new standards in accuracy, speed, and wireless operation. These innovations, driven by inventors and companies based in Luxembourg and the United States, helped shift handheld scanning from niche use to mainstream industrial and academic applications. [5][6][7]

Technical Principles

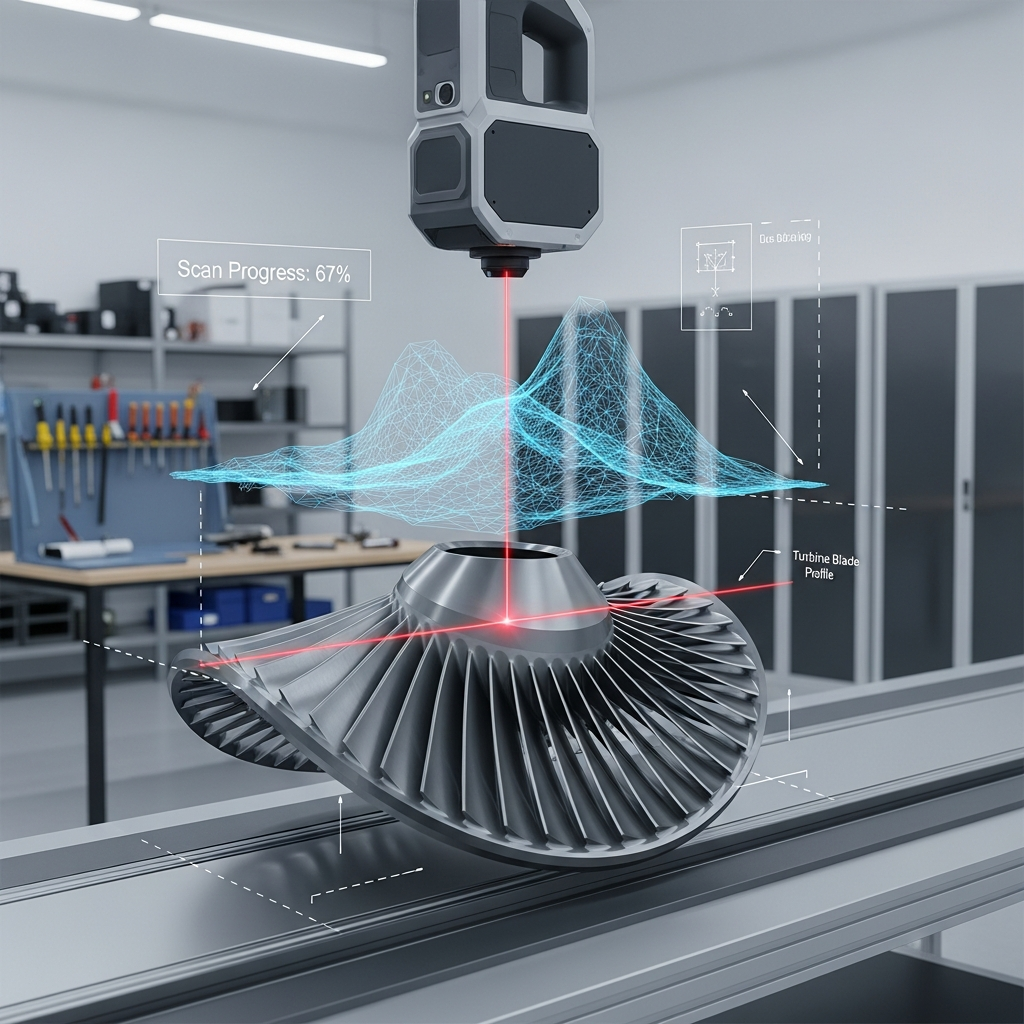

Handheld 3D scanners typically employ structured-light or laser-based technologies. Structured-light scanners, such as the Artec Eva, project a pattern onto the object, measuring the deformation to derive 3D geometry, while laser handheld 3D scanners emit a laser line to achieve similar results. Many modern portable scanners utilize target-free tracking, allowing software to follow the device’s position in real time—enabling single-operator workflows and accurate geometry acquisition. Industrial handheld 3D scanner accuracy typically ranges from 0.01 mm to 0.05 mm volumetric accuracy, with high-end systems boasting up to ≤ 0.005 mm—performance levels crucial to digital metrology and reverse engineering. [1][2]

Types of Handheld Scanners

Structured-light portable scanners, such as the Artec Eva, are widely adopted due to their ease of use and balanced performance. The Eva achieves up to 0.1 mm accuracy and up to 0.2 mm resolution, capturing scenes at approximately 16 frames per second and recording up to 18 million points per second. This type is commonly preferred for fast, non-contact measurements across general industrial and medical tasks. [5]

Laser metrology-grade handheld scanners, including the Artec Point, deliver exceptional precision—reaching 0.02 mm 3D point accuracy and volumetric accuracy of 0.015 mm + 0.035 mm/m, or 0.015 mm + 0.015 mm/m when paired with a Metrology Kit. These scanners can process data at 2.8 million measurements per second and support frame rates of up to 120 FPS, making them suitable for demanding environments like process control and quality assurance. Artec Leo, a wireless and standalone device, matches 0.1 mm accuracy and 0.2 mm resolution, but distinguishes itself by integrating onboard processing, enabling speeds up to 35 million points per second in HD mode. This makes the Leo ideal for fieldwork and complex shaped object capture where cable-free operation is needed. [1][3][7]

Comparison between models is recommended, as capabilities vary significantly. For instance, the Eva excels in versatility, the Spider II specializes in high-detail scanning (0.05 mm accuracy), the Point focuses on metrology precision, and the Leo offers the flexibility of wireless, standalone scanning.

Example models by type:

- Structured-light: Artec Eva, Artec Spider II

- Laser metrology: Artec Point

- Wireless/Standalone: Artec Leo

Performance

Accuracy & Resolution

Accuracy and resolution are highly model-dependent. The Artec Eva achieves up to 0.1 mm accuracy and 0.2 mm resolution, while the Spider II refines accuracy further to 0.05 mm and captures details at the same 0.05 mm resolution. The Artec Point, at the forefront of metrology, offers 0.02 mm point accuracy and superior volumetric performance. [1][3][5]

Speed & Data Rate

Data acquisition rates are critical in optimizing scanning productivity. The Artec Eva captures up to 18 million points per second at 16 FPS. The Artec Spider II fuses 30 frames per second, facilitating rapid, detailed scan assembly. The Artec Point, though tuned for metrological applications, gathers data at a rate of 2.8 million measurements per second with capture speeds reaching 120 FPS—crucial for live quality control during production. The Leo, leveraging advanced onboard processing, achieves up to 35 million points per second in HD mode, supporting quick scene digitization and immediate visualization on a built-in display. Such speeds are beneficial for both high-throughput inspection and field scanning tasks. [1][3][5]

Portability & Workflow

Portability distinguishes handheld 3D scanners from stationary systems. Models range from lightweight, cable-connected units to fully wireless, battery-powered solutions. The Artec Leo exemplifies advanced portability with rugged design, battery use, embedded processing, and target-free tracking. Operators can move freely, working independently without laptops or tripod mounts, greatly streamlining workflows during field inspections or large object scans. [7]

Comparison Table: Key Specifications of Leading Handheld 3D Scanners

| Model | Accuracy | Resolution | Data Rate | Standalone | Wireless | Weight (approx.) |

|---|---|---|---|---|---|---|

| Artec Eva | 0.1 mm | 0.2 mm | 18 M pts/s, 16 FPS | No | No | 0.85 kg |

| Artec Spider II | 0.05 mm | 0.05 mm | 30 FPS (fusion rate) | No | No | 0.85 kg |

| Artec Point | 0.02 mm | N/A | 2.8 M meas/s, 120 FPS | No | No | 0.94 kg |

| Artec Leo | 0.1 mm | 0.2 mm | 35 M pts/s (HD mode) | Yes | Yes | 2.6 kg |

Applications

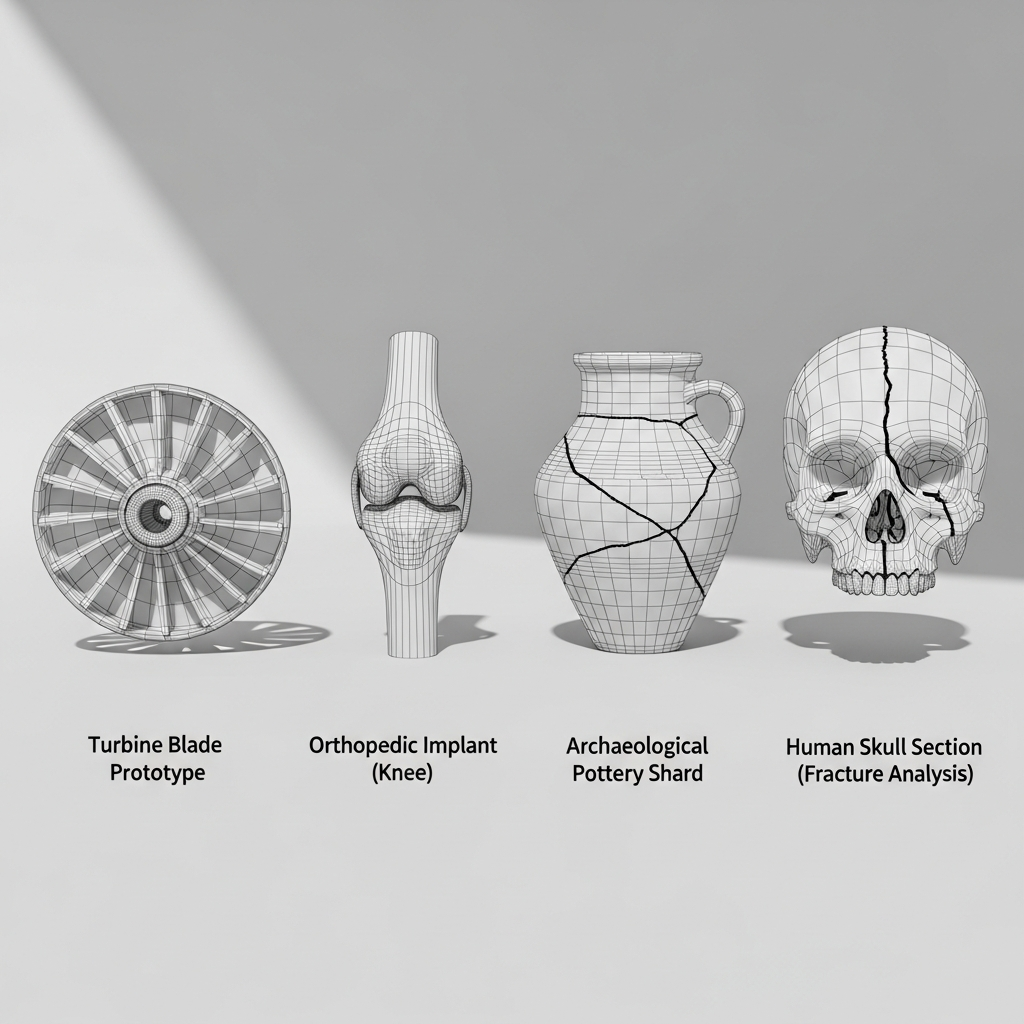

Handheld 3D scanners serve a wide array of applications, enabling rapid digitization in quality control, reverse engineering, cultural heritage preservation, and medical measurement. They have even found use in unconventional fields, such as the development of custom lingerie fit through 3D scanning (as seen in 2011) and archaeological artifact capture, leveraging portable, non-contact measurement to document fragile objects. [6]

Industrial case studies also highlight widespread use:

- Automotive prototyping and component validation

- Turbine blade inspection for aerospace and energy sectors

- Design and verification of orthopedic implants in healthcare

- Field inspection of pipelines, construction elements, and historical sites

These capabilities allow organizations to create accurate digital twins, support manufacturing iteration, and preserve delicate sites or objects with minimal risk of physical interaction. [2]

Research Updates

Recent improvements in handheld 3D scanner technology include wireless, embedded data processing (notably in the Artec Leo), the use of artificial intelligence and machine learning for automated 3D reconstruction, and adaptive calibration features such as active temperature control to maintain accuracy during long scanning sessions. The 2022 Artec Leo upgrade exemplifies these trends, offering higher maximum data rates, real-time HD mode, and cloud-based workflow integration. No reliable figure found from peer-reviewed research publications directly comparing latest commercial and laboratory prototypes, as most recent performance claims are based on vendor technical documentation. [7]

Q&A (FAQ)

1. What is the typical accuracy of a handheld 3D scanner?

Industrial handheld 3D scanners generally achieve volumetric accuracy within the 0.01–0.05 mm range. Leading-edge models may reach ≤ 0.005 mm, making them suitable for rigorous metrology applications. [2]

2. How fast can a portable scanner capture data?

Speed varies by model: the Artec Eva collects 18 million points per second, the Artec Point measures at 2.8 million measurements per second, while the Artec Leo attains up to 35 million points per second in HD mode—one of the fastest available. [3][5][7]

3. What are the differences between structured-light and laser handheld scanners?

Structured-light handheld scanners project a visible pattern onto a surface to generate a 3D reconstruction, as used by the Artec Eva. Laser handheld 3D scanners, such as the Artec Point, emit a laser line for high-precision acquisition—enabling greater accuracy and robustness in challenging surface conditions. [1][5]

4. In what industries is mobile 3D scan most beneficial?

Handheld 3D scanners have critical roles in automotive prototyping, aerospace turbine inspection, orthopedic implant design, field metrology, and heritage documentation—industries valuing non-contact, on-site 3D measurement. [2]

5. How does volumetric accuracy specification differ from point accuracy?

Point accuracy refers to the smallest detectable difference between individual 3D points, while volumetric accuracy—such as 0.015 mm + 0.035 mm/m for Artec Point—accounts for both baseline device error and accumulated positional error over a length, making it vital for large object scans in metrology. [1]

6. What advancements do standalone wireless handheld scanners like the Leo bring to metrological workflows?

Stand-alone wireless scanners like Artec Leo integrate onboard processing, real-time reconstruction, wireless data transfer, long-life batteries, and advanced calibration. These features streamline complex workflows by eliminating the need for external computers, cables, and markers during scanning tasks. [7]