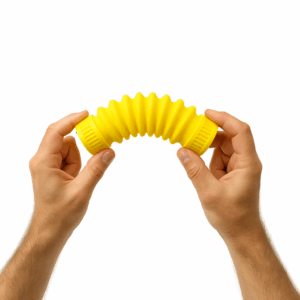

If you’re already familiar with 3D printing, you’ll likely have used materials like PLA & ABS quite a bit. If you’re looking to take things up a notch, the next step is often seen as switching to high-temperature filaments, such as PEKK, PEEK, or flexible elastomers like TPU.

But what do newcomers need to consider when making this upgrade? In reality, it has as much to do with your 3D printer as the material – it’s best to use an enclosed system. Though it’s not mandatory, this is likely to improve quality, while reducing instability and warping. Application is also important: making a flexible toy is one thing, 3D printing insoles is another entirely.

So, there’s a lot to consider. Let’s keep things simple by starting with some essential tips on making things with flexible materials, then moving on to the different types of filament.

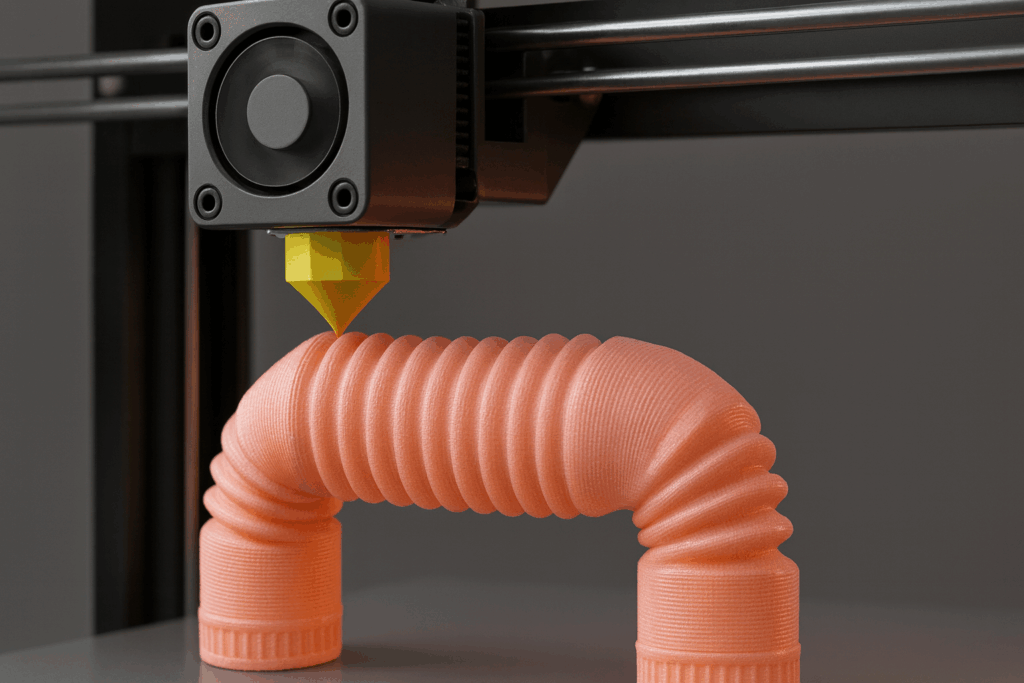

3D printing flexible filament

Flexible 3D printer filaments are seen as “next-level” because they deliver results not possible with rigid materials, but newcomers should consider the following when getting started:

Hardware: Direct-drive extruders are easier to begin with, constraining filament prevents tangling, and wider nozzle sizes (0.5 to 0.6mm) are likely to prevent clogging.

Settings: With print speed, it’s best to start slow (let’s say around 20-40mm/s) and try to avoid retraction, to reduce risk of jamming. Also, don’t overdo cooling – it can affect bonding.

Handling: Flexible filament like TPU/TPE is prone to water absorption, so keep these materials in dry/warm conditions. Carefully loading soft filament is also important to preventing issues!

Design: Try to minimize overhangs (as you can imagine, weak materials aren’t great here). With infill you can experiment: low infill results in squeezable parts, high infill raises rigidity.

Post-processing: Weigh up where supports are going to be needed, removing them can be messy and time consuming. Special paints are also required for additional coloring. Heat forming is possible for late design touch-ups, but this is more of a pro-level tip!

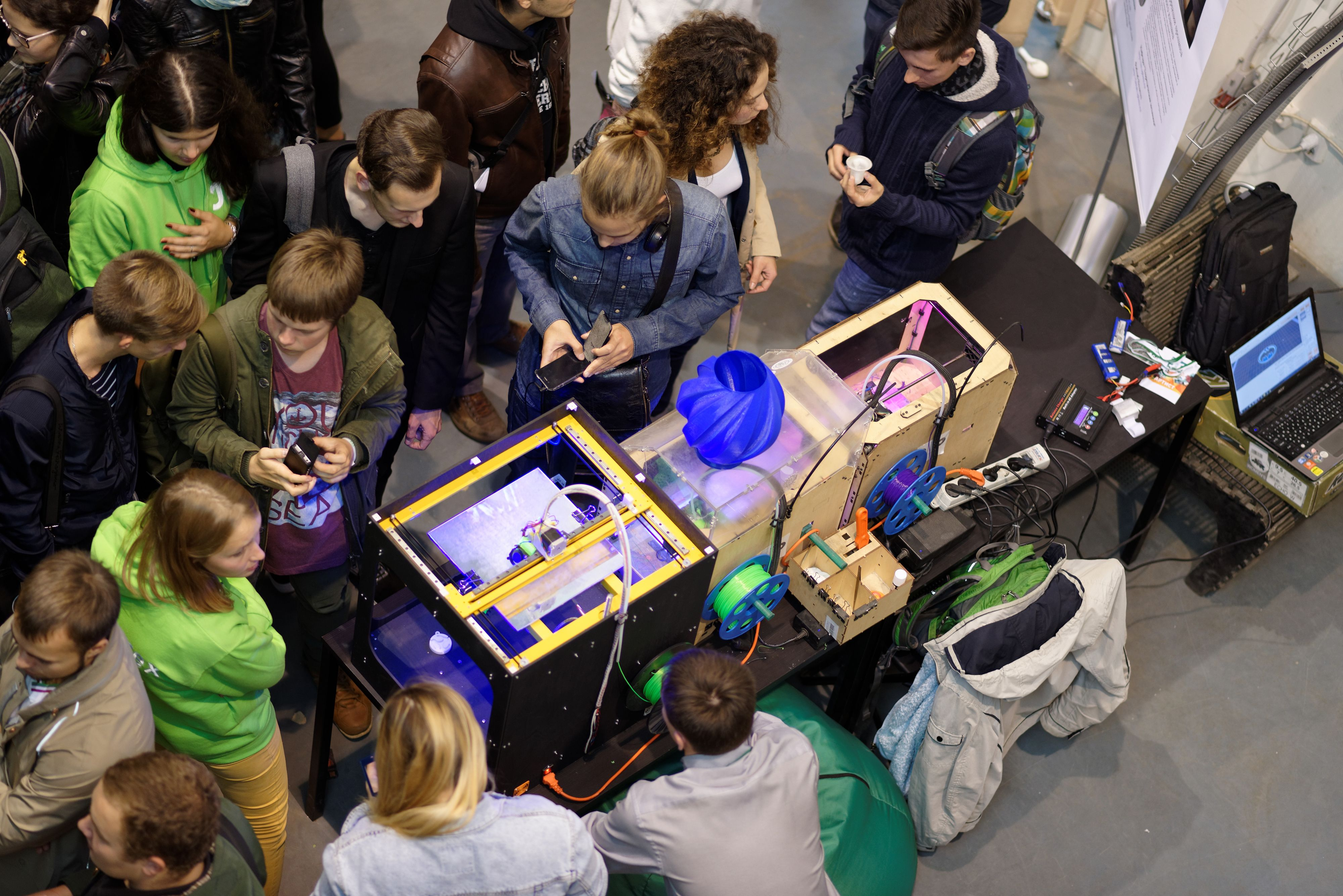

Best 3D printer for flexible filament

We won’t go into too much detail about the best 3D printers for flexible filaments. To find the ideal make and model, check out our rundown on the best 3D printers of 2025.

That said, there are a few things you can look out for. When getting started, it’s easy to make mistakes, so it’s advisable to buy a machine with a strong community following. Creality, Prusa, and Bambu Lab all sell in huge numbers and offer their own troubleshooting guides.

Features like automatic bed leveling simplify tasks that commonly lead to print failures. As mentioned earlier, enclosures are also important to achieving high quality results. When it comes to other specifications, bed, nozzle, and extruder setup are the key differentiators.

Removable build plates aid part removal, all-metal hotends better handle higher temps, and Bowden extruders are great – but less advisable for the inexperienced. Whichever system you choose, the possibilities are almost endless. From phone cases to medical wearables, 3D printing with flexible materials unlocks new applications for makers and professionals alike.

Best flexible 3D printer filament

There are many types of flexible 3D printing filament out there. To keep things neutral, we won’t mention any brand names here. For a more complete deep-dive, we suggest that you check out our most recent 3D printing material guide.

TPU (Thermoplastic Polyurethane)

Probably the most widely used flexible polymer in the 3D printing industry, TPU offers a great mix of elasticity, toughness, and ease of printing. Typically available with a shore hardness of 85A-95A, the material can be used to make pretty durable parts e.g. joints or RC car tires.

TPE (Thermoplastic Elastomer)

With a shore hardness of 70-90A, TPEs tend to be softer than other flexible 3D printing materials. This “squishier” feel can make it tougher to print, but unlock applications where a greater amount of give is required, such as gaskets or stress-relieving components.

Soft PLA (Polylactic acid)

Essentially just a softer form of PLA, this material is much easier to print than regular elastomers. The main drawback is its limited “bendiness” – it’s not particularly rubbery. As a result, it’s best deployed in areas that rely more on high impact resistance than flexibility.

Flexible Nylon

For more demanding use cases, flexible nylon offers flexibility and high toughness/chemical resistance. Okay, the material is more demanding to use. Expect higher printing temperatures, demanding filament storage requirements, and even potential issues with bed adhesion. But the result is arguably worth it for end-users seeking final engineering parts they can rely on.

Specialized filaments

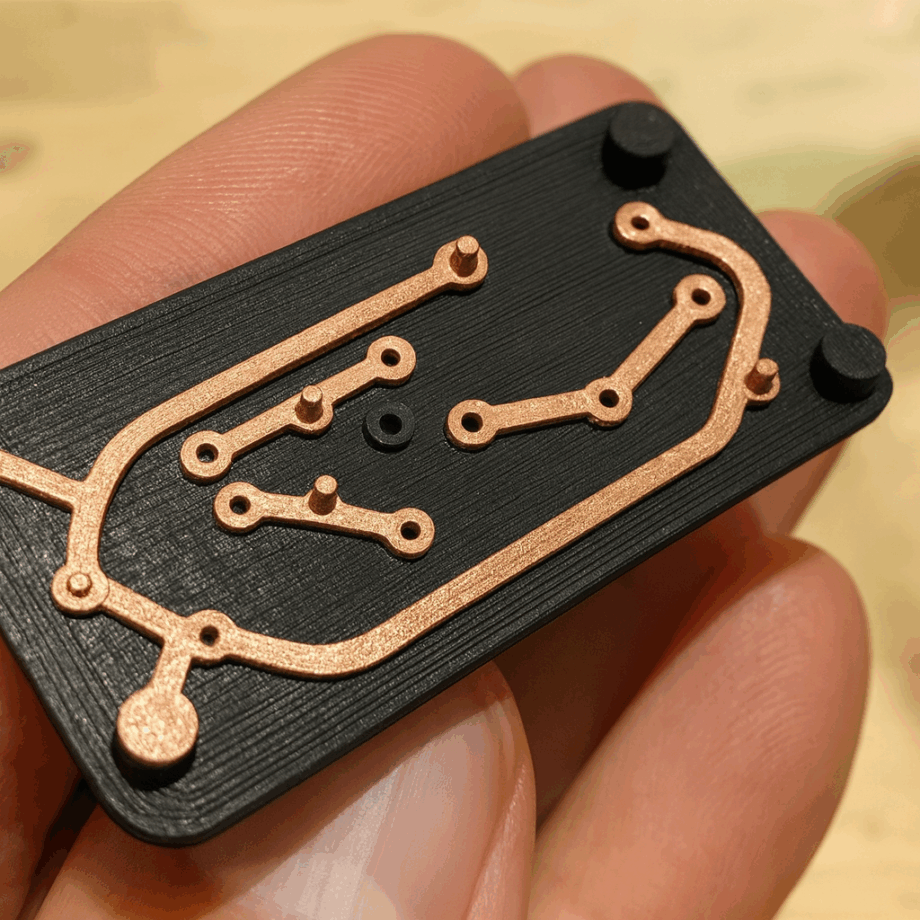

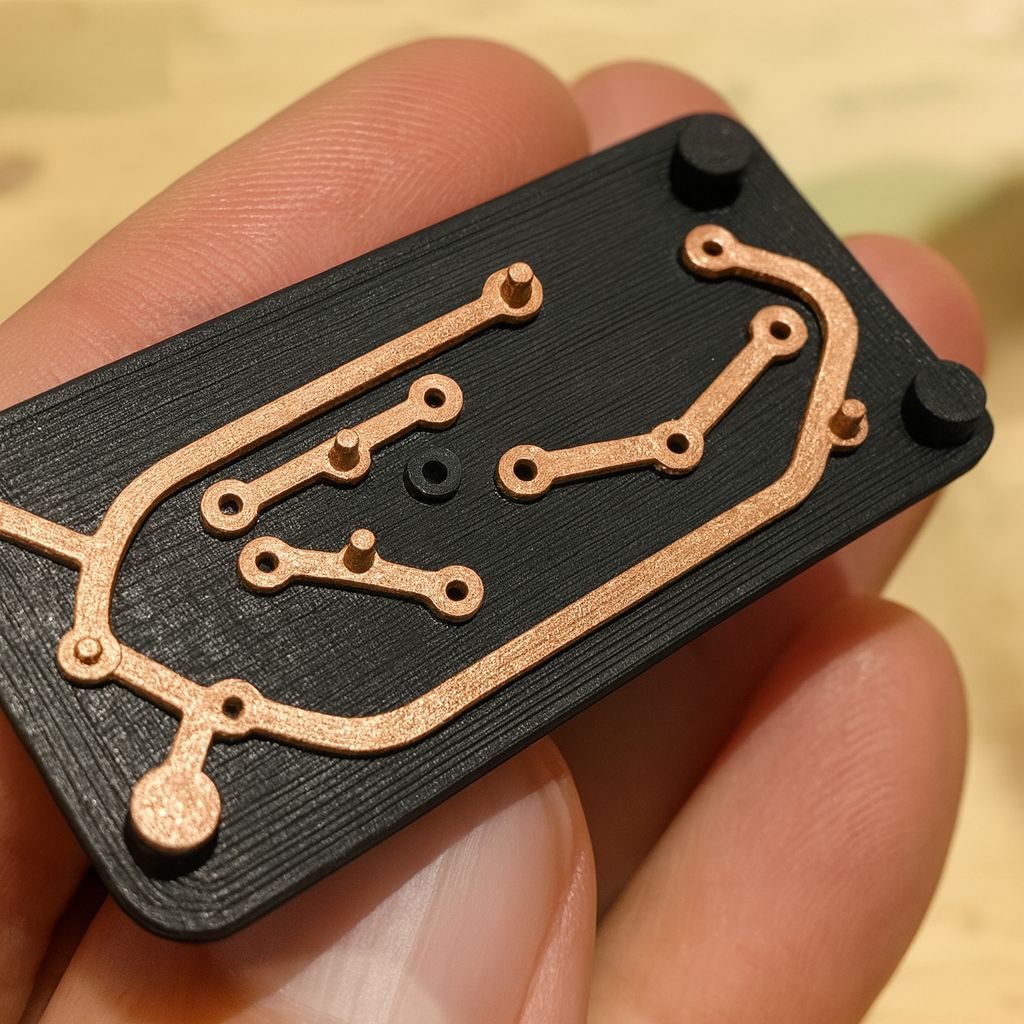

Depending on the industry, you may also be able to find more dedicated filaments on the market. Those making parts exposed to electricity can use conductive polymers. Medical-grade TPUs/TPEs also allow for skin-contact, while high-temperature materials deliver peak durability.

How to get started with flexible 3D printing

It’s easier than ever to get started with 3D printing, getting involved is simply a case of investing in a machine. You can avoid a lot of trial and error by following the tips outlined above, or visiting the support site of your favored device. Complete newcomers are best served by beginning with regular ABS or PLA, before experimenting with more ambitious projects.

But once you’ve got the hang of things, the sky really is the limit. Why not 3D print repairs for around the house? Or better yet, get hold of a cheap 3D scanner or photogrammetry software and digitize people or everyday objects and 3D print a real-life replica? Whether you’re a maker or business user, all the tools are out there, it’s just about getting to grips with them!