Earlier this year, 3D printing material supplier SUNLU launched its very first high-temperature filament dryer, the FilaDryer E2, featuring built-in annealing functionality.

For those unaware, many 3D printing materials are hygroscopic, meaning that if left to their own devices, they’re naturally prone to absorbing moisture from the air. Even popular filaments like PLA, ABS & TPU are affected, making this a relatively common 3D printing problem.

Despite the fact moisture absorption can cause filaments to swell, bubble, or even break during extrusion, many makers and engineers don’t take the issue seriously. That’s why 3D Mag sat down with SUNLU’s Mathieu Noguier to find out when filament drying is necessary and how results can be so profound that they open entirely new use cases to operators.

What is filament drying?

While there are plenty of DIY filament drying methods out there, you’ll get better results with a purpose-built piece of kit. Most commercial devices come with temperature and humidity control, as well as the ability to dry damp materials in approximately 4-12 hours.

Each dryer has a unique configuration, but most feature some kind of heating element that keeps filaments below their glass transition point to prevent deformation (usually this is 40-80°C). For even drying, warm air is circulated around spools with a fan. Some also have dehumidifying technology, which removes moist air from inside the chamber.

Other beneficial add-ons include real-time humidity monitoring, pre-set timer and temperature modes, and direct 3D printer feeding. But the results of filament drying are generally the same: improved print consistency and fewer costly errors.

When do I need a filament dryer?

Filament dryers are especially useful when working in high-humidity, poorly ventilated environments, as moisture can interfere with materials in hours. Obviously, some materials are more vulnerable to warping than others, but Mathieu says advanced users are worse affected.

“Filament drying is not something you would think of when you’re just entering 3D printing as a hobbyist. But it’s actually a very important topic,” he explained. “Not all filaments are the same when it comes to moisture sensitivity. So if we’re talking about PLA, it’s pretty stable. But when we get into more engineering filaments like nylon, PC, ABS, these are really more sensitive.”

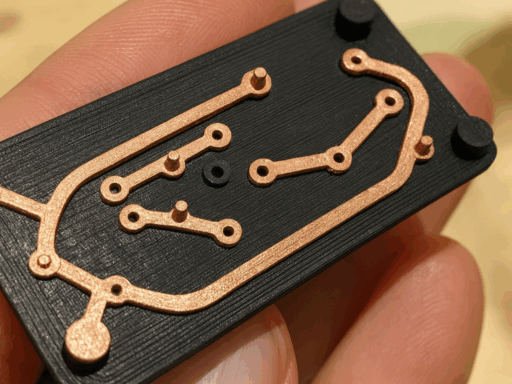

Though everyday 3D printing materials like PLA, ABS, and Nylon are all hygroscopic to some degree, SUNLU has identified a need specifically for high-temperature filament drying. Often used to create end-use parts, engineering polymers require better strength, stability, and mechanical properties – all aspects that can be improved with drying and annealing.

That’s why SUNLU has introduced the FilaDryer E2, a 2-in-1 system that both dries and anneals materials. For annealing newcomers, this is the process of heating then slowly cooling polymers to reduce residual stress and enhance durability. SUNLU says the FilaDryer anneals “99.99% of engineering materials” at up to 110oC for models with “extraordinary impact resistance.”

Unlocking new 3D printing possibilities

Though SUNLU continues to market many hobbyist-level solutions, its new FilaDryer is built to help users take the next step into final part production. According to Mathieu, the launch was very much designed to meet rising customer demand – particularly in areas like automotive.

“The main benefit [of materials annealed by the FilaDryer E2] is high temperature resistance. In automotive, that’s a huge step towards the ability to 3D print end-parts that fit directly into production cars,” explained Mathieu. “At last year’s Formnext, we didn’t have a solution for this, and received that feedback a lot. I guess that’s the advantage of having an office in Europe, you really tend to hear market feedback faster!”

Moving forwards, SUNLU sees potential for its machine in other areas too. High-performance filaments play a key role in the production of industrial tooling and prototyping. For just a few hundred extra dollars, manufacturers stand to benefit from significantly reinforced parts.

This also applies to makers. Citing a real use case, Mathieu says he 3D printed a reinforced hanging device for his heavy winter jacket, having already broken a regular hanger. This kind of application illustrates the FilaDryer E2’s potential as a tool for creating everyday items like clips, mounts, and holders. Given the system’s four-kilo capacity, this kind of approach arguably has commercial potential as well, in the creation of larger parts and batches without reloading.

SUNLU’s engineering-grade goals

While the idea of ‘industrial-grade 3D printing’ isn’t new in the maker space, there has also been a clear recent trend towards improved access to engineering-grade materials.

Of course, SUNLU isn’t the only manufacturer of filament dryers on the market. But in launching the FilaDryer E2, it has recognized this growing demand for more capable solutions. In the years to come, Mathieu says his firm will continue to serve entry-level customers while stepping up its higher end offering, both in the shape of hardware and new material formulations.

“At SUNLU, we really want to open the door to high-end industries like automotive and industrial manufacturing using 3D printing,” he concluded. “Not through developing the generic filament we produced before, but creating a new range of engineering filaments, like PA12. This will be our main step for 2025, finding a way into these kinds of industries that are still quite niche places, as far as 3D printing filament manufacturers are concerned.”

SUNLU aren’t the only ones pushing the limits of additive manufacturing. Find out more about desktop 3D printing, or discover the latest 3D printing material advances here.