A next-gen magnetic mixer built at MIT could help solve one of the most persistent challenges in 3D bioprinting. MIT News reports that researchers in the Department of Mechanical Engineering have created “MagMix,” an onboard device that keeps bio-inks uniformly mixed while printing, enabling more reliable and scalable manufacturing of 3D-printed tissues. The study, recently published in Device, details how the technology actively prevents cells from sinking during long print sessions.

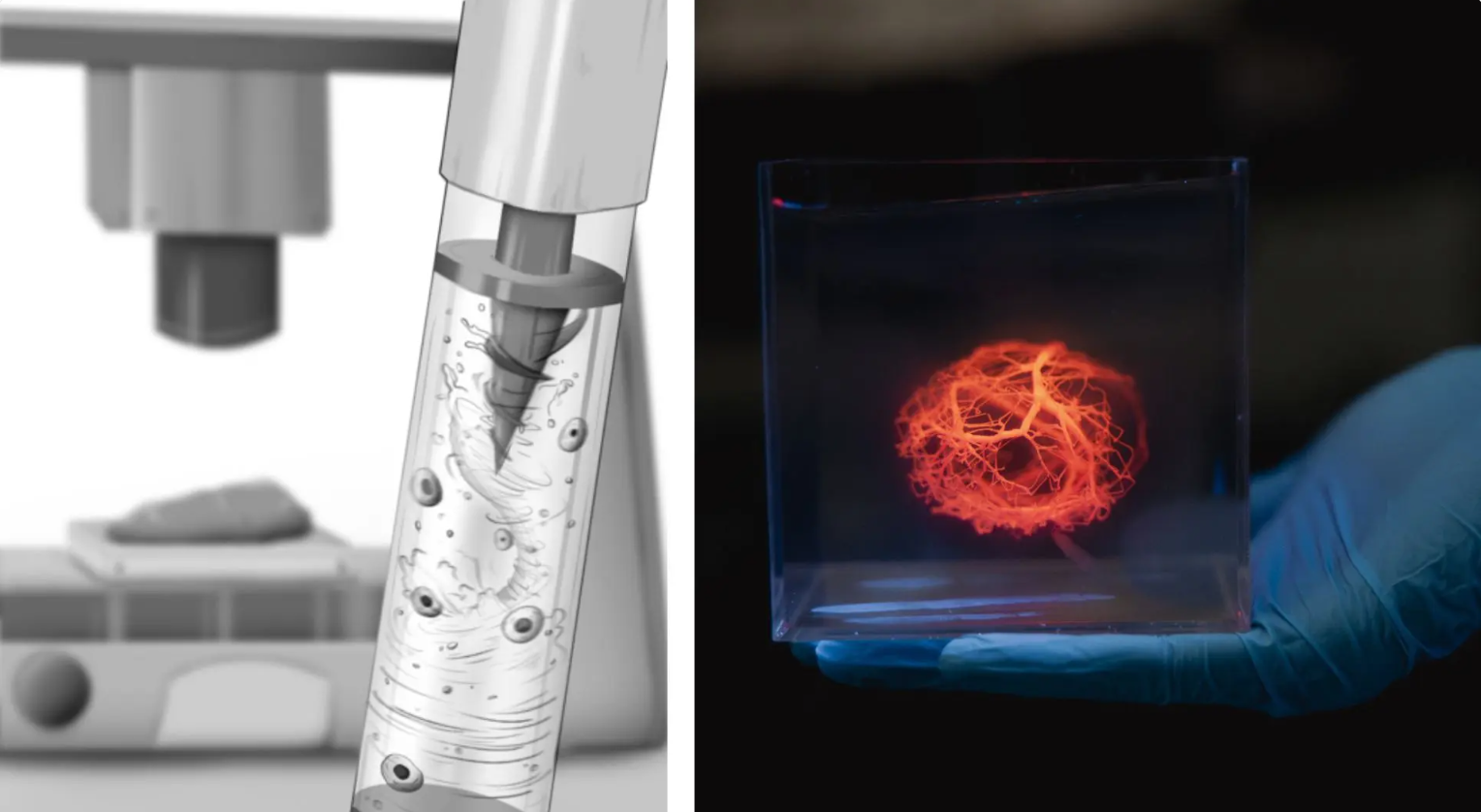

In extrusion 3D bioprinting, living cells are suspended in soft hydrogels called bio-inks and deposited layer by layer to form tissues. However, gravity creates a challenge. “This cell settling, which becomes worse during the long print sessions required to print large tissues, leads to clogged nozzles, uneven cell distribution, and inconsistencies between printed tissues,” Ritu Raman, the Eugene Bell Career Development Professor of Tissue Engineering at MIT, explained. “Existing solutions … cannot maintain uniformity once printing begins.”

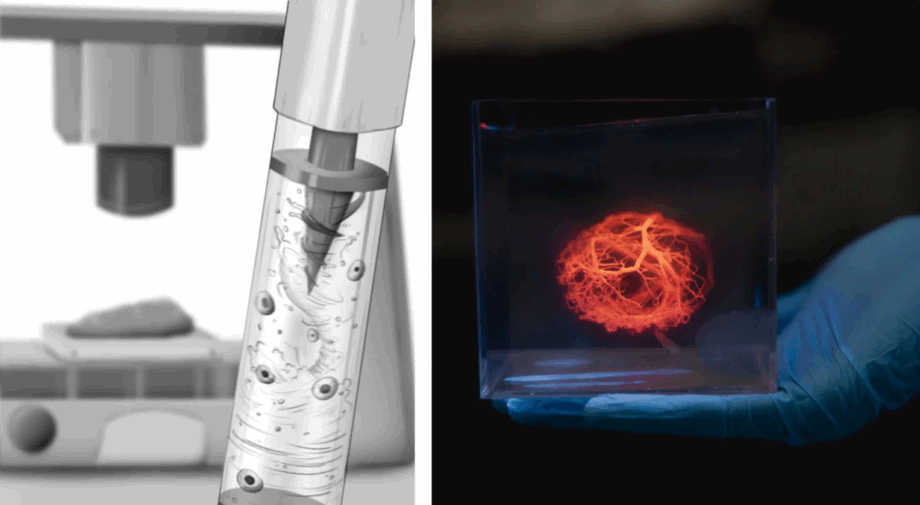

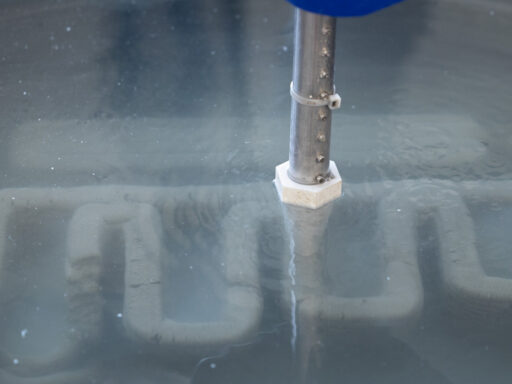

MagMix tackles this problem with a compact, magnetically actuated mixer that contains two parts: a small magnetic propeller inside the printer syringe and a permanent magnet attached to a motor outside the syringe. The external magnet moves up and down, driving the internal propeller – this provides gentle, tunable-speed, real-time mixing, preventing any alterations in the bio-ink formula or disrupting the printer’s operation.

“Precise control over the bio-ink’s physical and biological properties is essential for recreating the structure and function of native tissues,” said lead author Ferdows Afghah.

According to Raman, in testing, “MagMix prevented cell settling for more than 45 minutes of continuous printing, reducing clogging and preserving high cell viability”. The team managed to demonstrate that printed cells are capable of maturing into muscle tissue over several days.

Supported in part by MIT’s Safety, Health, and Environmental Discovery Lab (SHED), the project aims to make engineered tissues more reproducible and accessible. Potential applications range from drug screening to regenerative medicine and even biohybrid robotics.