An advancement from the University of Illinois Urbana-Champaign could redefine how manufacturers track and verify their supply chains. Researchers, led by Professor Bill King of the Grainger College of Engineering, have developed an artificial intelligence system that can identify the origin of 3D printed parts, right down to the specific machine that produced them.

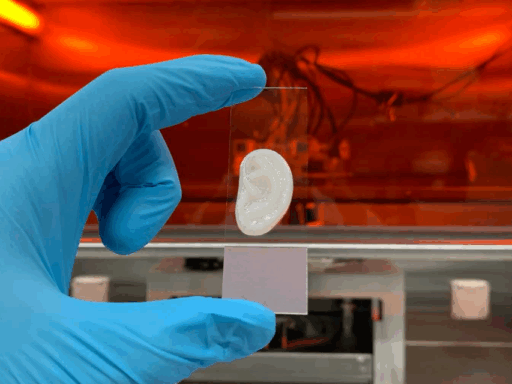

By analyzing high-resolution photographs, even those taken with smartphone cameras, the AI system is capable of detecting even subtle variations on the part’s surface, the unique “fingerprints” left by each 3D printer. “We are still amazed that this works,” said King. “You don’t have to take your supplier’s word on anything.”

A joint effort by King, Miles Bimrose, Davis McGregor, Charlie Wood, and Sameh Tawfick, and published in Advanced Manufacturing the study states that these machine-specific signatures can be identified with 98% accuracy from just one square millimeter of a part’s surface. The model was trained on 9,192 parts produced by 21 machines across six companies and four fabrication methods.

The implications are profound: manufacturers can now verify that suppliers adhere to agreed-upon processes and detect unauthorized changes early, all with no need for costly audits or inspections. “Modern supply chains are based on trust,” King explained. “But this technology gives manufacturers the means to verify and trace exactly where and how a part was made.”

Beyond quality control, this innovation could also help trace the origins of counterfeit or illicit goods, bringing a whole new layer of transparency in global manufacturing.