Seattle-based software company Dyndrite has signed a multi-year licensing agreement with aerospace and defense innovator Ursa Major, marking a major stride in advancing metal additive manufacturing for next-gen propulsion systems.

Under the agreement, Ursa Major will adopt Dyndrite LPBF Pro, a GPU-accelerated software toolkit. Designed for metal 3D printing, LPBF Pro will support material development, part qualification, and scalable production of high-performance rocket engines. The collaboration follows a thorough six-month evaluation in which Dyndrite’s technology outperformed existing tools across both engineering and manufacturing workflows.

Ursa Major is known for its work with laser powder bed fusion (LPBF) in propulsion systems, so it is a logical step for the company to integrate Dyndrite software into its Draper engine line. These engines feature such advanced capabilities as vector control, throttle adjustability, and mission restarts.

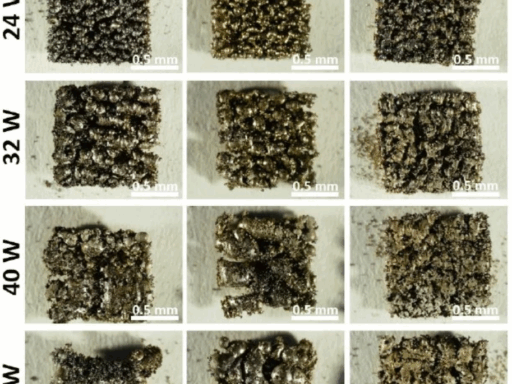

“It’s been exciting working side by side with Ursa Major’s engineers,” Steve Walton, head of product at Dyndrite, said in a press release. “LPBF Pro consistently solved challenges legacy tools couldn’t – reducing support needs, improving surface finish, and enhancing microstructure consistency.”

“Dyndrite’s tools help us scale complex hardware across platforms. Together, we’re breaking through technical barriers to deliver next-generation propulsion systems, manufactured faster and at scale,” added Thomas Pomorski, director of additive manufacturing at Ursa Major.

Dyndrite LPBF Pro offers a scriptable CAD-to-Print environment and process development tools for agile, traceable production, bringing a new dimension of efficiency and precision to additive manufacturing.