The Control exhibition in Stuttgart, Germany may be best known as a metrology convention, but this year’s show featured many 3D scanners alongside traditional measurement equipment.

Control 2025 marked the 37th edition of the international trade show, which has long been a staple in the calendar of leaders from across the quality assurance space. During the event, the focus seemed to shift towards efficiency, process optimization, and value creation – with a variety of new technologies on display designed to provide visitors with fresh impetus.

3D Mag was live on the showfloor, ducking and diving between booths to find the most innovative products. Many of these turned out to be 3D scanners, but AI-powered automation and AR also featured heavily throughout the show. Here’s what we found!

Innovation at Zeiss, Artec 3D & Fraunhofer

Immediately, one of the first things visitors will have noticed at this year’s exhibition was the booth of ZEISS. Its display was absolutely massive – the size of several stands combined. At the show, the metrology leader exhibited the robotic arm-mounted Atos 5, alongside its newly launched ScanPort 3D scanner – a 3-axis, compact modular device for smallish parts.

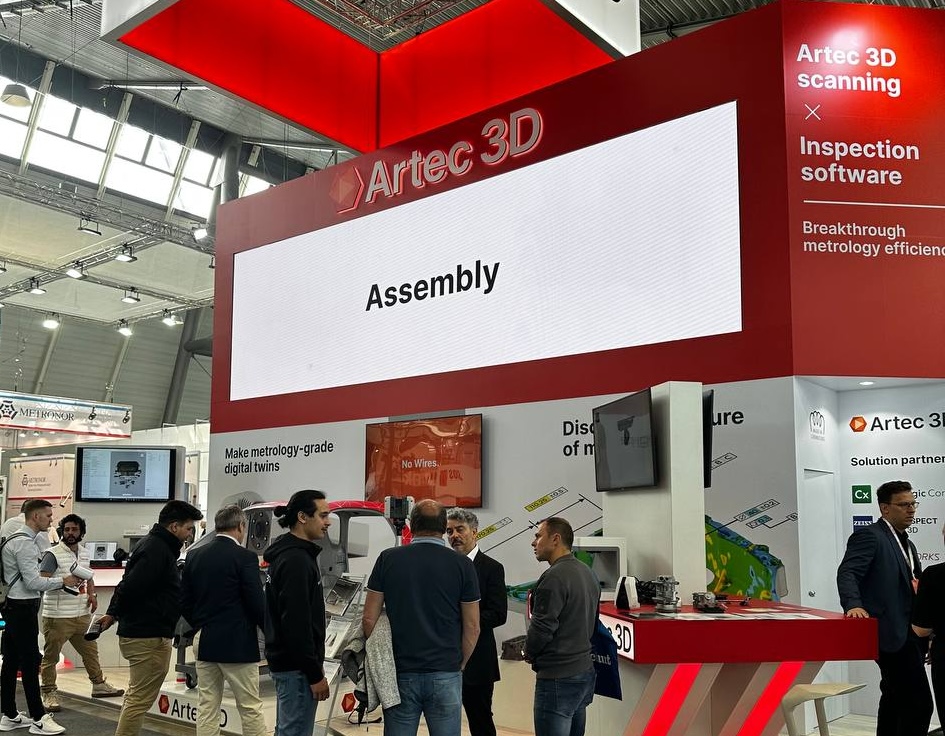

Artec 3D also had a huge booth on which it showcased its two new handheld 3D scanners: the ultra-high resolution Artec Spider II and metrology-grade Artec Point. While the former digitizes small-to-medium parts in fine detail, the latter is better suited to high accuracy measurement within industrial environments (so it was very much at home at the Control exhibition).

They shared a booth with software specialists from Geomagic – which was recently acquired by Hexagon – another of the leading industrial technology firms at the show. According to experts on the booth, Artec Studio now has many of the reverse engineering and inspection essentials, but programs like Design X and Control X offer tools for more demanding use cases.

At the booth of Fraunhofer IOF, researchers were showcasing something a bit different: a 3D scanner mounted to a robot dog. Debuted at last year’s event, GoScout3D is now being marketed as a solution for digitization at scale. To demonstrate these possibilities, they had a Boston Dynamics walk around a large assembly, presumably scanning it for quality control.

Next-level automation at Adcole & Hexagon

Alongside a rise in 3D scanning representation on the showfloor, this year’s Control Expo was characterized by further advances in AI and automation. Throughout the show, industry stalwart Adcole showcased the OptiShaft: a high-precision tactile measurement machine. Though the device is already well-established in automotive, its software is now powered by AI.

According to Adcole itself, the technology will provide users with access to new interfaces that relieve operators of hands-on tasks, in a way that reduces inspection lead times and costs.

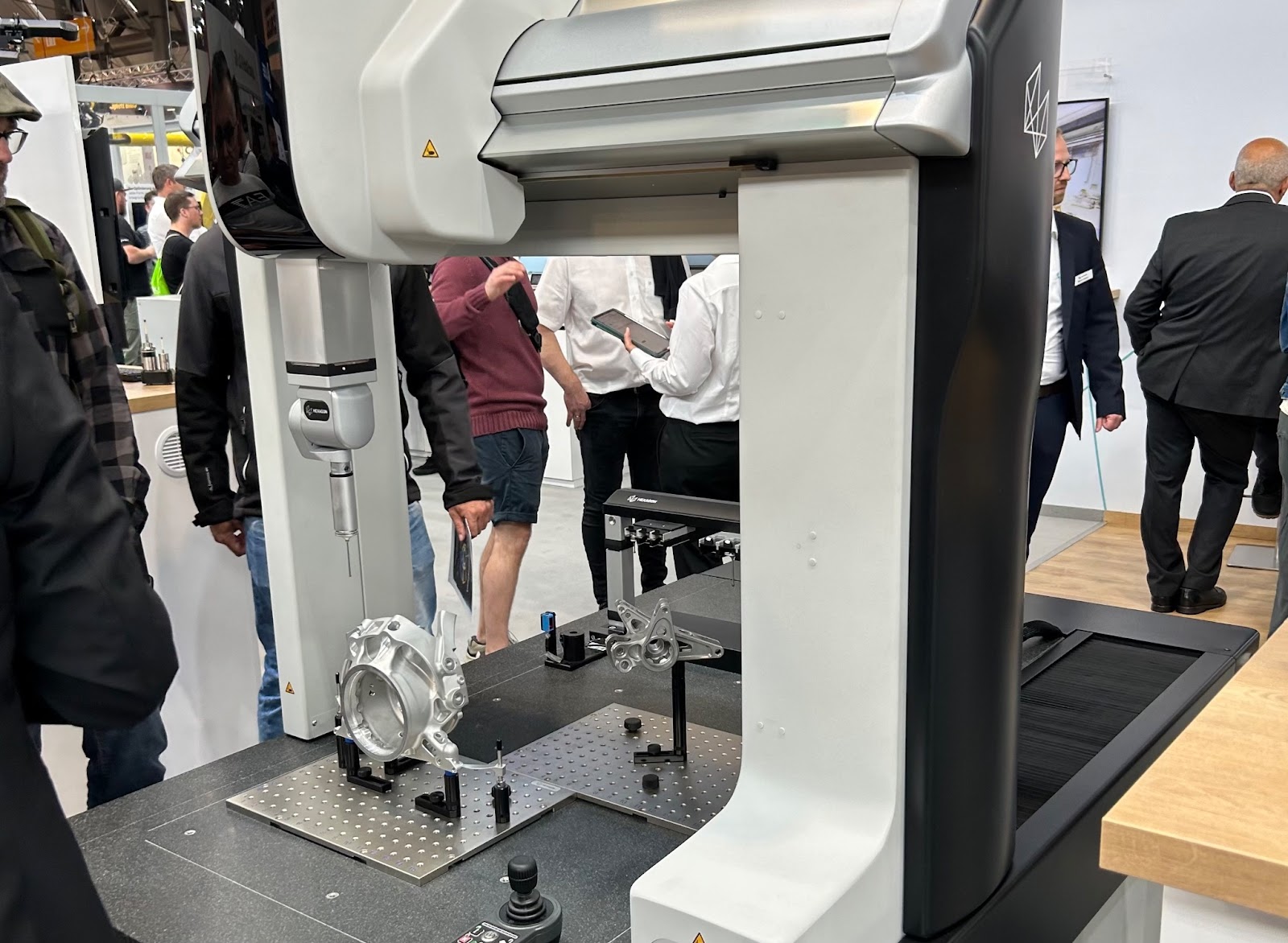

Hexagon also debuted its new MAESTRO CMM machine. Designed to facilitate greater integration with digital workflows and drive overall workflow efficiency, the system is expected to deliver high speed and accuracy probe-based measurement for those working in the most demanding industries. Thanks to Hexagon’s Nexus software, MAESTRO also shares real time data for seamless cross-department workflows and the setting up of an interconnected IoT.

AR leads the way in inspection software

Augmented reality solutions also seemed to be in high demand – and the likes of CDMVision attracted considerable attention with their SuPAR solution. At its booth, the company’s team showed how it’s now possible to inspect a car chassis in real time with AR overlays.

Obviously, the level of accuracy that’s achievable with AR is limited at around 1mm, but it was claimed that automotive OEMs such as BMW and Volkswagen already have that number down to 0.6mm. The software has nifty bespoke features for popular use cases such as spot welding and stud inspection. It also uses deep learning to continually improve accuracy and efficiency, so it could be an initial inspect solution to watch as the technology steadily evolves.

The same could be said for another AR solution provider at the show: Visometry. During the Control exhibition, the firm showcased Twyn 2.4, the latest version of its inspection software which now includes Assisted Deviation Detection for immediate scan-CAD analysis. Again, the program is designed for analysis right there, on-the-spot, on the shopfloor.

At its booth, the Visometry team were also measuring a vehicle, but the technology is said to have significant potential everywhere from aerospace to shipbuilding and the rail industry.