Summary

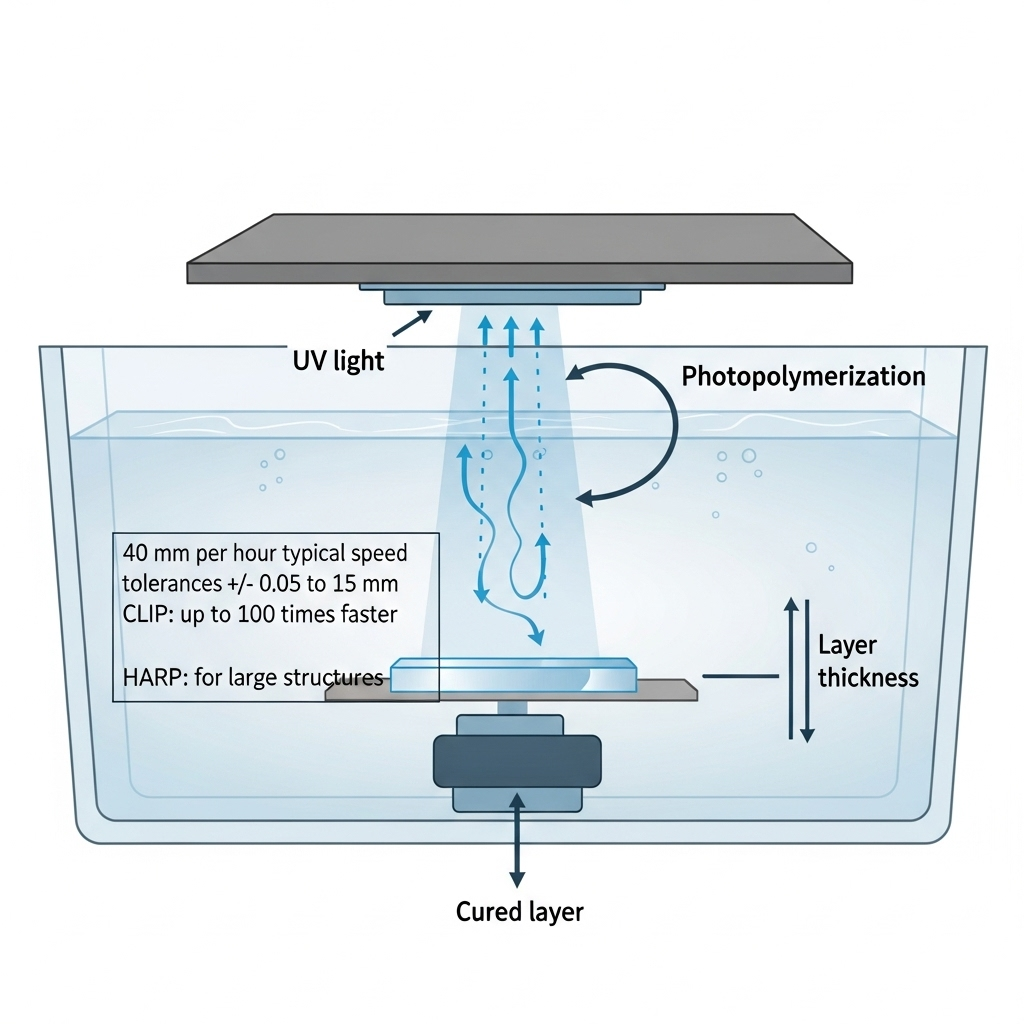

Resin 3D printing — also called stereolithography (SLA), resin printing, and UV resin printing — uses the photopolymerization of liquid thermoset resins to build 3D objects layer by layer. The technology originated with Chuck Hull’s 1984 patent (granted in 1986), enabling high-precision objects with typical speeds of 40 mm/hour and tolerances in the ±0.05–0.15 mm range. Today’s research methods, including CLIP (up to 100× faster) and HARP for large structures, push the boundaries of what’s possible. [1] [2] [3] [4] [9] [10]

Historical Background

The earliest precursor to resin 3D printing emerged from Hideo Kodama’s pioneering work in 1981, where he published details on using a UV light to harden liquid resin in layers — the world’s first photopolymer 3D fabrication approach. A few years later, in 1984, Chuck Hull filed the patent for stereolithography (SLA), a method enabling the solidification of UV-curable resin into precise 3D forms. This patent was granted in 1986, and Hull subsequently co-founded 3D Systems, launching the SLA-1 — the first commercial stereolithography machine. SLA-1 beta units shipped in January 1988, with the first production hardware emerging in April 1988. [1] [2] [3]

Throughout the 1990s and early 2000s, SLA technology evolved from expensive, industrial platforms to more affordable machines. In 1992, digital light processing (DLP) — a related vat polymerization technology — appeared, and by 2001, compact desktop SLA systems reached professionals and hobbyists. [12]

Technical Principles

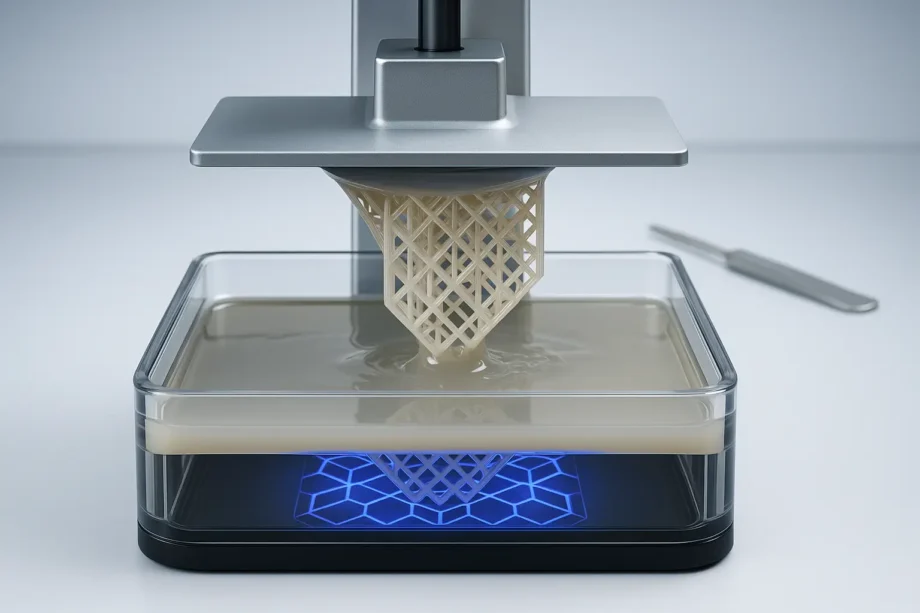

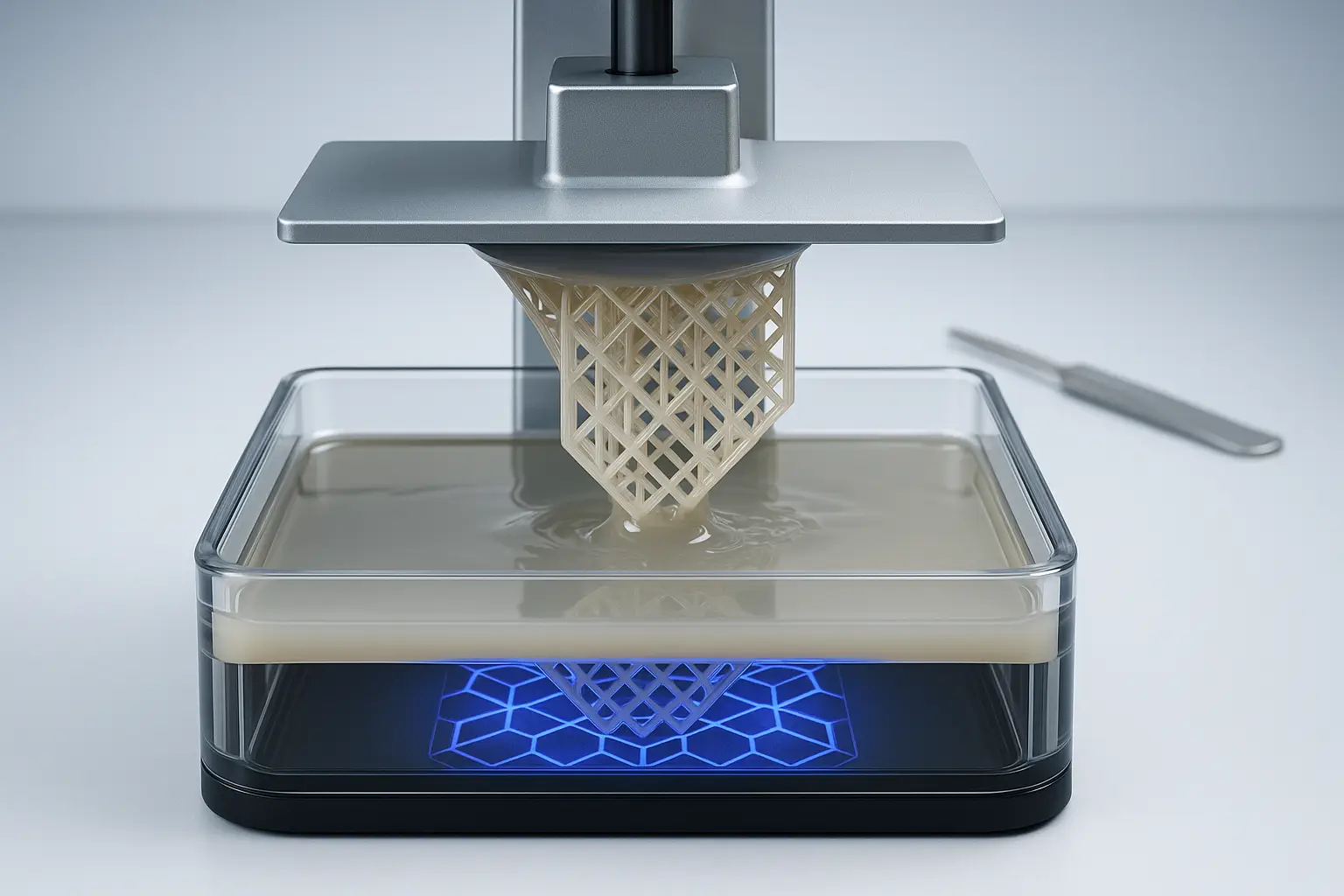

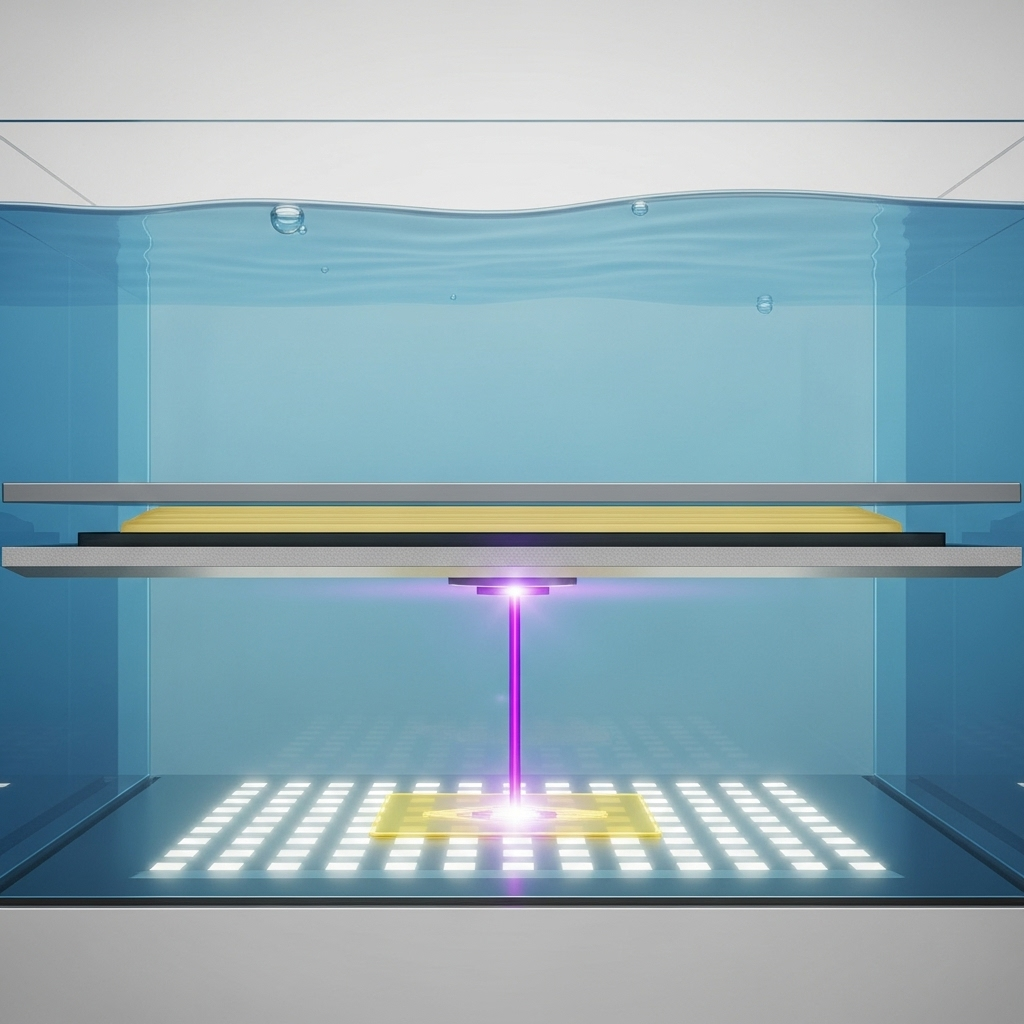

Stereolithography (SLA) is the foundational process behind resin 3D printing, encompassing technologies that use photopolymerization — the solidification of photosensitive liquid resins via targeted ultraviolet (UV) light exposure. In typical SLA systems, a UV laser or a digital array projects light into a shallow vat of resin, transforming material into thin, precise layers. Key variants include laser-based SLA, digital light processing (DLP), and masked stereolithography (MSLA), each varying in how the UV energy is delivered. The resins themselves comprise different photopolymer blends, allowing for a wide range of mechanical properties, surface textures, and functional applications. [1]

Performance

Speed and Throughput

Modern masked stereolithography (MSLA) printers such as those from Formlabs average around 40 mm/hour, though speeds can vary between 16–50 mm/hour depending on material and settings. With the advent of continuous methods like CLIP (Continuous Liquid Interface Production), resin print speeds reportedly reach up to 100 times faster than traditional approaches. [4] [10]

Accuracy and Tolerance

Resin 3D printing is renowned for its high accuracy and excellent surface finish, driven by both hardware precision and material properties. According to Formlabs’ technical specifications, dimensional tolerances for their printers are: ±0.15% for features 1–30 mm (minimum ±0.02 mm); ±0.2% for 31–80 mm (±0.06 mm); ±0.3% for 81–150 mm (±0.15 mm). In independent industry guides, general SLA tolerances of ±0.05 to ±0.15 mm are typical, with sub-100 mm parts often holding within ±0.05 mm. Surface accuracy for dental restorative models reveals exceptional fidelity: 99.7% of all measured surfaces are within 100 µm, 95% within 50 µm, and 69% within 25 µm. However, one challenge is resin shrinkage, which varies by formulation. Recent scientific studies measured volumetric shrinkage for new experimental formulations as low as 7.28%, compared to 7.66–11.2% in other standard resins — a critical factor in achieving highly accurate and stable parts. [4] [5] [6] [7] [8]

Key Performance Metrics

- Print Speed: MSLA (Formlabs): average 40 mm/hour; CLIP up to 100× faster.

- Dimensional Tolerance: Formlabs: ±0.15% (1–30 mm); industry SLA: ±0.05–0.15 mm.

- Surface Fidelity: 99.7% (≤100 µm); 95% (≤50 µm); 69% (≤25 µm).

- Material Shrinkage: 7.28% (experimental); 7.66–11.2% (other resins).

Comparative Table: Traditional SLA vs. CLIP

| Metric | Traditional SLA | CLIP (Continuous) |

|---|---|---|

| Average Print Speed | 40 mm/hr | Up to 4,000 mm/hr (claimed) |

| Tolerance (typical) | ±0.05–0.15 mm | Comparable or higher |

| Shrinkage (%) | 7.28–11.2 | Depends on resin |

| Typical Max Build Size | Medium | Larger possible (via HARP) |

| Surface Accuracy | 99.7% (≤100 µm) | High, fast curing supports |

Applications

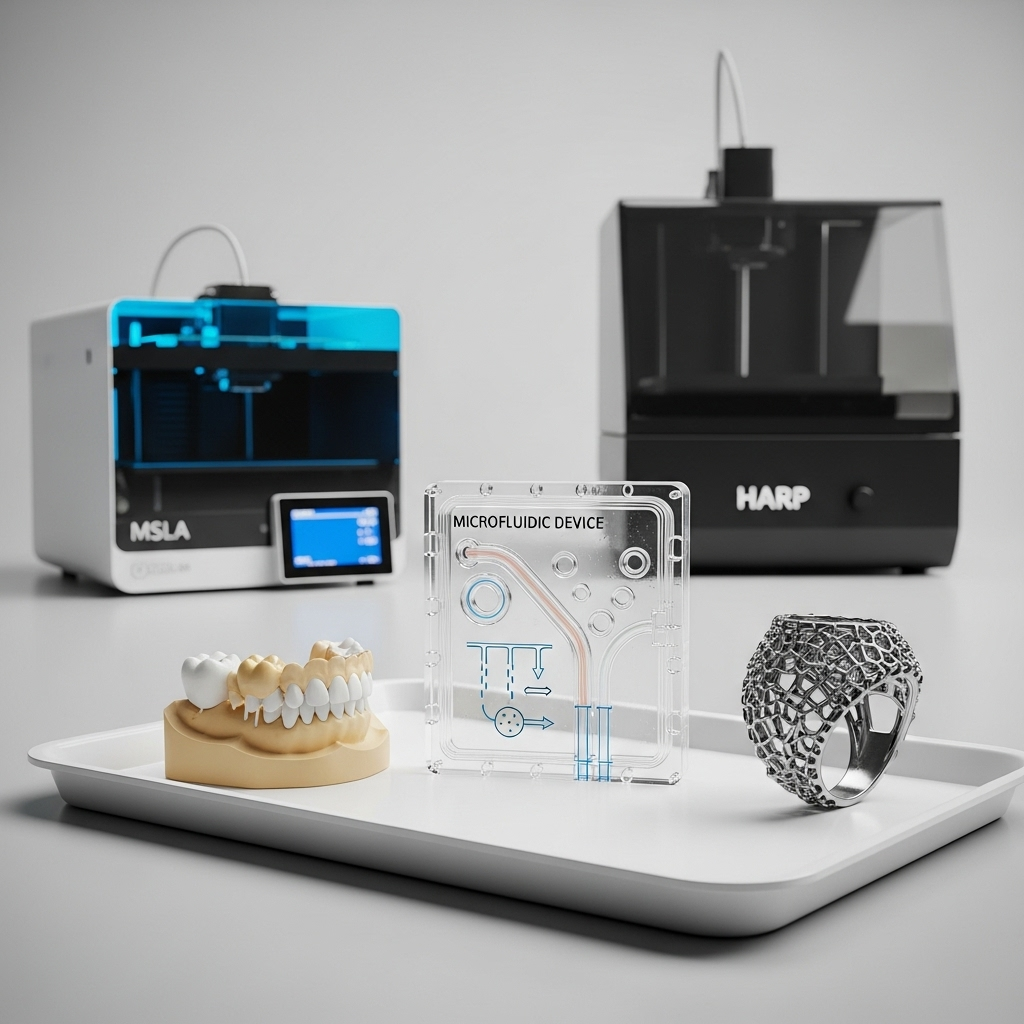

Resin 3D printing’s precision and versatility make it indispensable across prototyping, dental and medical modeling, jewelry, microfluidics, and high-performance functional parts. In the medical and dental sectors, the technology enables the fabrication of restorative models, surgical guides, and patient-specific implants with outstanding geometric accuracy. Product designers rely on SLA for rapid iteration of highly detailed prototypes, while industrial engineers use tough, specialized UV resins for end-use parts. Advances like HARP (high-area rapid printing) extend the technology’s reach to large-scale structures and high-throughput manufacturing lines, opening new possibilities for batch production where exceptional surface finish is mandatory. [1] [4] [9]

Research Updates

Recent research in resin 3D printing has focused on achieving unprecedented speed and scale. CLIP technology enables continuous, non-layered curing as much as 100 times faster than standard resin systems. HARP, introduced in 2019, scales up the process for large objects. Further, innovative low-shrinkage resin chemistries reported shrinkage reductions to 7.28%, making production of dimensionally stable parts more feasible. [8] [9] [10]

FAQ

What is resin 3D printing and how does stereolithography differ?

Resin 3D printing refers to technologies that use photopolymer resins cured by UV light to create objects layer by layer, with stereolithography (SLA) being the first and most widely recognized process. SLA uses a laser to selectively cure liquid resin, producing highly precise and smooth parts. [1]

What typical print speeds can users expect with SLA resin printers?

Modern desktop SLA and MSLA printers, such as those from Formlabs, average print speeds of 40 mm/hour, with possible ranges of 16–50 mm/hour depending on the resin and settings. Cutting-edge continuous systems like CLIP can be up to 100 times faster under ideal conditions. [4] [10]

What are common dimensional tolerances in UV resin printing?

Industry-standard tolerances for UV resin (SLA) printing are typically in the range of ±0.05 mm to ±0.15 mm, with parts under 100 mm in size often within ±0.05 mm. Manufacturers such as Formlabs specify ±0.15% for small features and up to ±0.3% for larger features. [5] [6] [7]

How does shrinkage vary across resin formulations, and why does it matter?

Shrinkage in photopolymer resins results from polymerization and evaporation during curing. Standard formulations display volumetric shrinkage between 7.66% and 11.2%, but recent innovations have achieved as low as 7.28%. Lower shrinkage helps maintain dimensional accuracy, crucial for engineering and dental applications. [8]

What continuous methods like CLIP or HARP offer over traditional resin printing?

CLIP and HARP represent continuous resin printing technologies, offering dramatically higher throughput — CLIP can achieve speeds up to 100 times that of standard SLA, while HARP supports much larger build volumes. These advances address bottlenecks in speed and scalability present in conventional layered approaches. [9] [10]

What applications benefit most from high surface accuracy in resin printing?

Applications that require intricate details and flawless surface finish, such as dental models, jewelry prototypes, microfluidic devices, and custom surgical guides, especially benefit from the high surface accuracy achievable with resin 3D printing. Consistent surface fidelity supports both appearance and fit. [4] [6]

Sources

- Wikipedia: Stereolithography (SLA)

- Wikipedia: 3D Printing

- Wikipedia: 3D Printing (SLA-1 Beta Shipments)

- Formlabs Resin 3D Printer Tech Specs

- Formlabs: Accuracy and Tolerances

- Formlabs: Surface Accuracy Data

- SGD3D: SLA 3D Printing Accuracy Guide

- MDPI Polymers: Resin Shrinkage Article

- Wikipedia: High-area Rapid Printing (HARP)

- Wikipedia: Continuous Liquid Interface Production (CLIP)

- Wikipedia: Stereolithography — Materials

- Raise3D: History of Resin 3D Printing