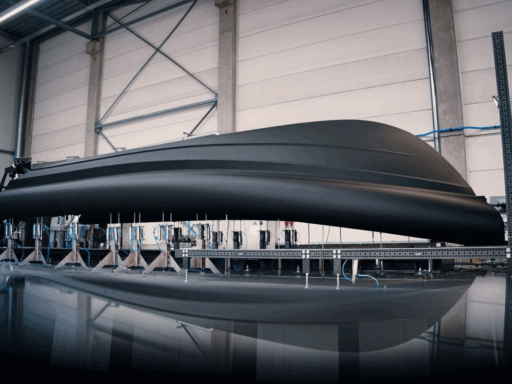

Last week Apple opened pre-orders for iPhone Air, with availability starting tomorrow, September 19. This is the thinnest iPhone to date at just 5.6 millimeters, and it also marks a turning point in smartphone manufacturing with the integration of 3D printing into one of the world’s most iconic devices.

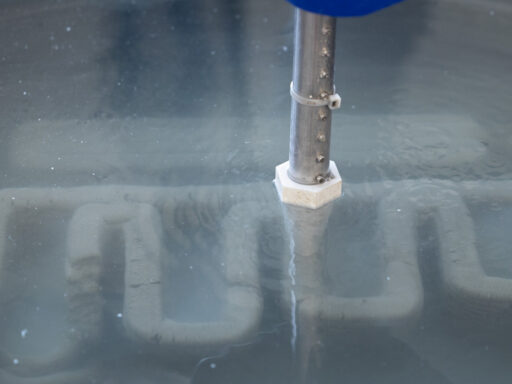

The new model boasts a titanium USB-C port made with additive manufacturing. With the help of 3D printing, Apple engineers made the component both thinner and stronger while cutting material use by 33 percent compared to conventional production. With the company making a pledge to be carbon neutral across its operations by 2030, this could be the first step in a larger shift, where new methods like additive manufacturing are playing a transformative role.

“The all-new iPhone Air is so powerful, yet impossibly thin and light, that you really have to hold it to believe it’s real,” John Ternus, Apple’s senior vice president of Hardware Engineering, said in a press release. “This huge leap in design and engineering is only made possible through Apple innovation, especially Apple silicon.”

Beyond the port, the iPhone Air features a titanium frame, Ceramic Shield 2 protection on both front and back, and a reimagined internal architecture that frees up more space for the battery. The 6.5-inch Super Retina XDR display offers up to 3000 nits peak brightness, the highest yet on iPhone. The device runs on the new A19 Pro chip, together with Apple’s N1 wireless and C1X cellular processors, making it the most power-efficient iPhone so far.

Apple is planning to extend its 3D printing endeavors to more products: the upcoming Apple Watch 11 will feature a 3D-printed titanium case. These decisions are a good sign that additive manufacturing, traditionally used in aerospace and energy industries, is now gaining traction in consumer electronics.