Summary

ABS filament — a thermoplastic composed of acrylonitrile, butadiene, and styrene — is a leading material in 3D printing for engineering and industrial uses. ABS stands out for its mechanical strength, heat resistance, and glass transition temperature of approximately 105 °C, making it suitable for functional prototypes and parts that demand durability and higher temperature performance (en.wikipedia.org).

Historical Background

Acrylonitrile butadiene styrene (ABS) was first patented in 1948 and later commercialised in 1954 by Borg-Warner in the United States, marking its introduction as a novel engineering plastic (en.wikipedia.org).

Initially developed for the injection molding industry due to its impact resistance and machinability, ABS found broader adoption in 3D printing. Its durability, ease of post-processing, and mechanical resilience made it an ideal choice for functional prototyping, household products, and automotive parts.

Technical Principles

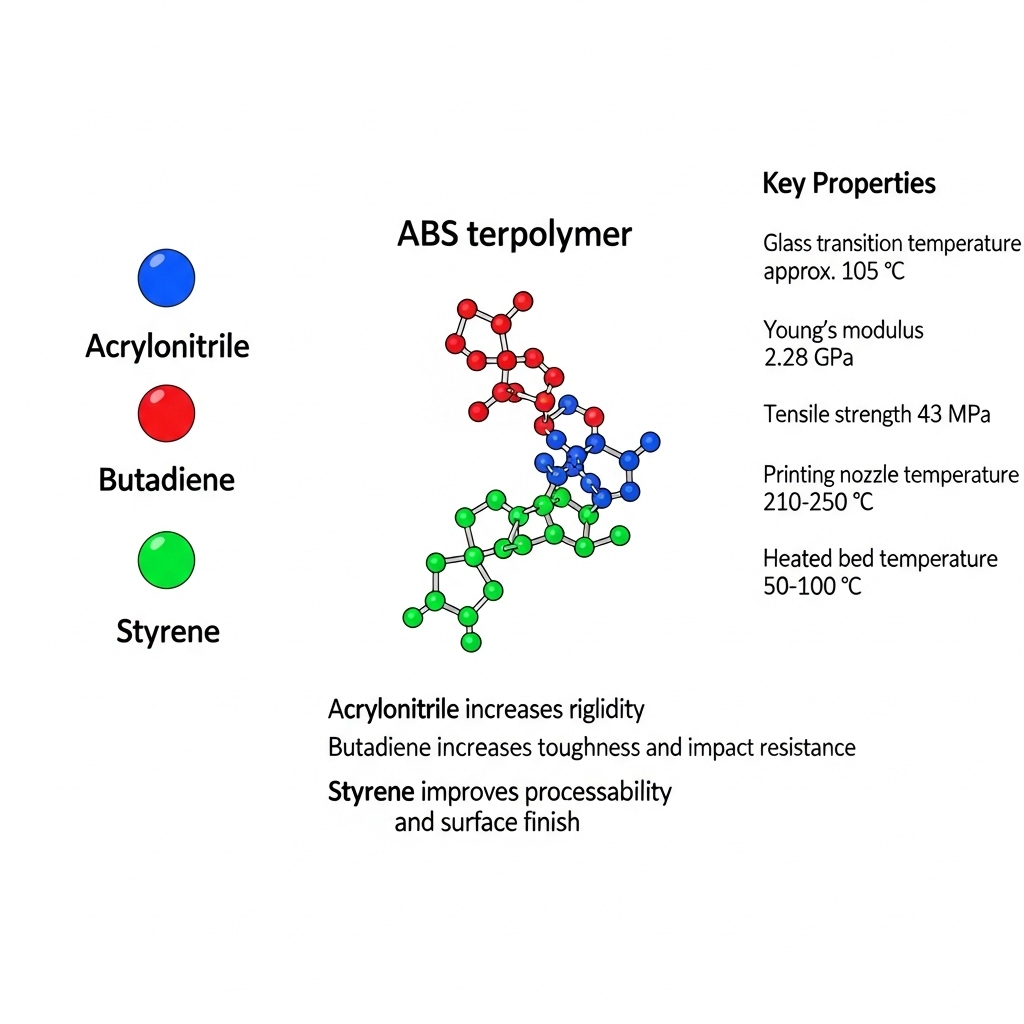

ABS is a terpolymer, formed by polymerizing acrylonitrile, butadiene, and styrene. The precise ratio of these monomers is adjusted to optimize properties such as rigidity, toughness, and processability, each component influencing specific performance metrics (en.wikipedia.org).

Material Properties

Mechanical Properties

ABS demonstrates a Young’s modulus of 2.28 GPa, indicating notable rigidity. It has a tensile strength of 43 MPa in standard form (en.wikipedia.org), with a reported tensile range for molded specimens of 29.6–48.0 MPa (juggerbot3d.com). Flexural strength reaches 77 MPa, while the elongation at break is approximately 53 %, suggesting balanced toughness and ductility (juggerbot3d.com).

Thermal and Density Properties

ABS’s glass transition temperature is reported as 105 °C (en.wikipedia.org), with some sources citing approximately 108 °C (juggerbot3d.com), reflecting minor variations across grades. Its density falls in the range 1.00–1.22 g/cm³, typical of engineering thermoplastics used for durable parts (engineersedge.com).

Printing Parameters

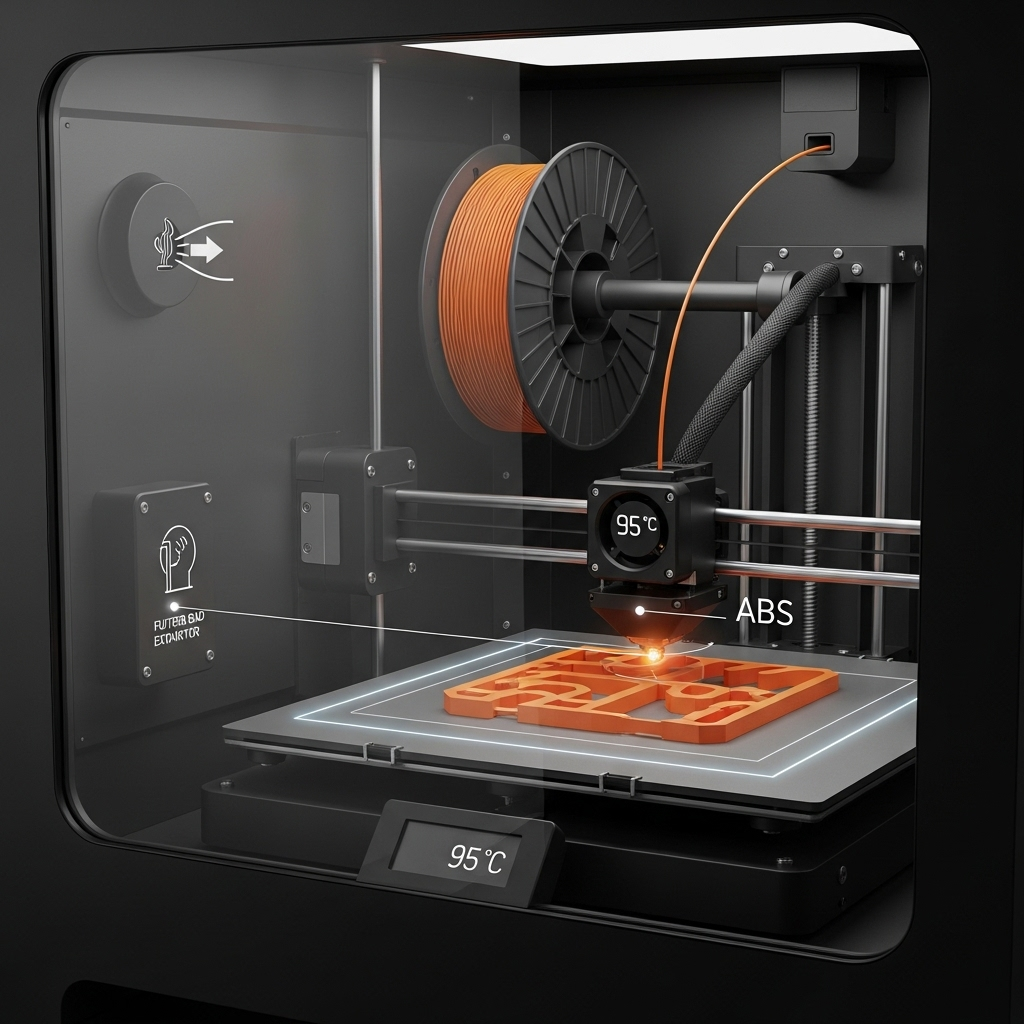

Standard ABS filament requires a nozzle temperature between 210–250 °C and a heated bed at 50–100 °C (en.wikipedia.org). Manufacturer-specific recommendations often center around 220–245 °C for extrusion and roughly 95 °C for the print bed (engineersedge.com), supporting optimal layer adhesion and minimizing warping.

Comparison with PLA

When compared with PLA, ABS exhibits a lower typical tensile strength (43 MPa) versus PLA’s 60–70 MPa but dramatically outperforms in impact resistance, recording values in the 20–50 kJ/m² range against PLA’s relatively modest 2–5 kJ/m² (ultirapid.com). This makes ABS the preferred option for parts that must endure drops or mechanical shocks.

ABS also differs from PLA in thermal behavior, offering a significantly higher glass transition temperature at approximately 105 °C, while PLA’s is around 60 °C (boyiprototyping.com). Printing ABS requires a heated bed and is often improved by using a printer enclosure due to its tendency to warp, whereas PLA prints easily without such measures (3dspro.com).

ABS vs PLA: Key Properties Comparison

| Property | ABS | PLA |

|---|---|---|

| Tensile Strength | 43 MPa | 60–70 MPa |

| Impact Resistance | 20–50 kJ/m² | 2–5 kJ/m² |

| Tg (°C) | 105 | 60 |

| Nozzle Temp (°C) | 210–250 | 180–220 |

| Bed Temp (°C) | 50–100 | Not required/50–70 |

| Elongation (%) | ≈53 | ≈6 |

Applications

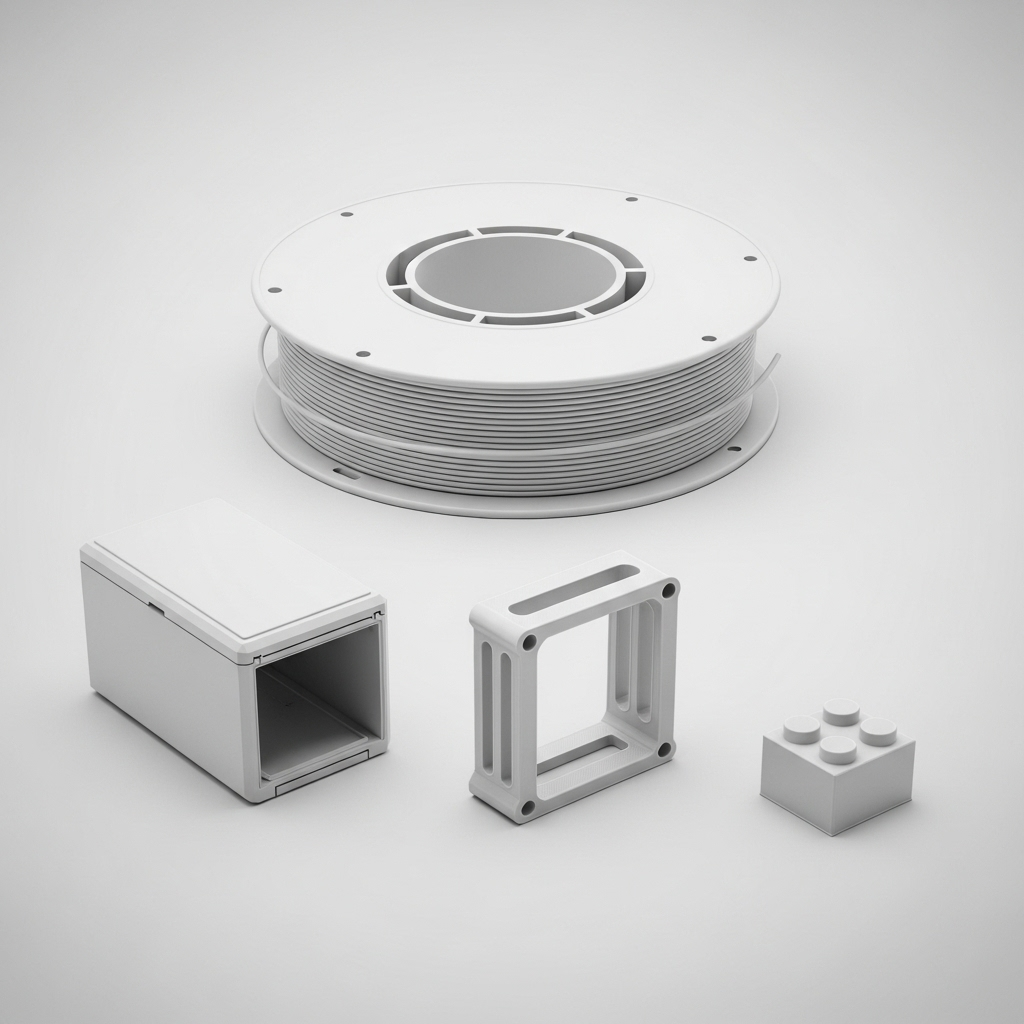

ABS filament is widely used for producing functional parts, prototypes, automotive components, enclosures for electronic devices, and toys, most notably LEGO bricks, which have been exclusively produced from ABS since 1963 (en.wikipedia.org).

Post‑Processing and Handling

ABS is highly amenable to various post-processing techniques, including acetone vapor smoothing, manual sanding, machining, and solvent gluing. In contrast, PLA offers limited compatibility with most solvents, making ABS the superior choice for models requiring a smooth, professional finish (boyiprototyping.com).

However, there are occupational and practical considerations when working with ABS. It emits fumes with a strong, sometimes unpleasant odor during printing, necessitating effective ventilation. Additionally, ABS’s susceptibility to warping obliges users to operate heated beds and consider using enclosures to stabilize ambient temperature and ensure print reliability (divbyz.com).

Q&A (FAQ)

What is ABS filament and why is it used in 3D printing?

ABS filament is a blend of acrylonitrile, butadiene, and styrene. It’s popular for its mechanical strength (Young’s modulus 2.28 GPa) and thermal stability (Tg 105 °C), making it well-suited for engineering-grade 3D printed parts (en.wikipedia.org).

How does ABS compare to PLA in strength and heat resistance?

ABS provides a tensile strength of about 43 MPa, while PLA can reach 60–70 MPa; however, ABS surpasses PLA in impact resistance (20–50 kJ/m² vs PLA’s 2–5 kJ/m²) and withstands higher temperatures with a Tg of 105 °C compared to PLA’s 60 °C (ultirapid.com).

What are the recommended printing temperatures for ABS filament?

ABS is typically printed with a nozzle temperature of 210–250 °C and a heated bed set between 50–100 °C. Practical manufacturer guidelines recommend 220–245 °C for the nozzle and about 95 °C for the bed (en.wikipedia.org).

How tough is ABS filament—what are its mechanical properties?

ABS offers a tensile strength of 43 MPa, a flexural strength of 77 MPa, and an elongation at break near 53 %, indicating a robust combination of rigidity and ductility (en.wikipedia.org).

What post‑processing techniques are effective for ABS filament?

Acetone vapor smoothing, sanding, machining, and solvent gluing are all effective for ABS. Caution is advised due to fume release and a tendency for parts to warp if improperly handled (boyiprototyping.com).

Why does ABS require an enclosure during 3D printing?

ABS demands an enclosure to reduce warping caused by rapid cooling and thermal contraction. Its glass transition temperature of approximately 105 °C makes it sensitive to ambient shifts; enclosed environments stabilize conditions and maintain mechanical properties (en.wikipedia.org).