Curtin University researchers are set to play a pivotal role in a new $271 million national effort to strengthen Australia’s advanced manufacturing sector through 3D printing innovation.

The Additive Manufacturing Cooperative Research Centre (AMCRC), that has just received a boost of $58 million in federal funding, unites 14 research institutions and more than 50 collaborators from the industry. Its goal is to create a nationally connected ecosystem for additive manufacturing across key sectors, including aerospace, automotive, defence, healthcare, and construction.

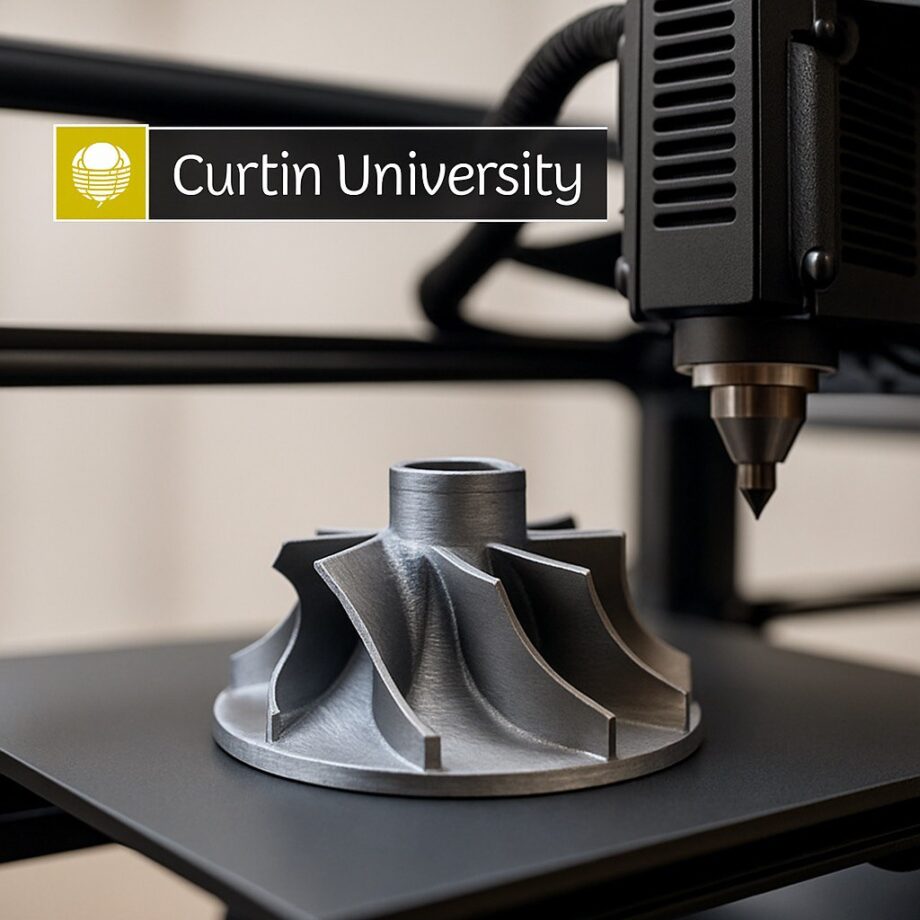

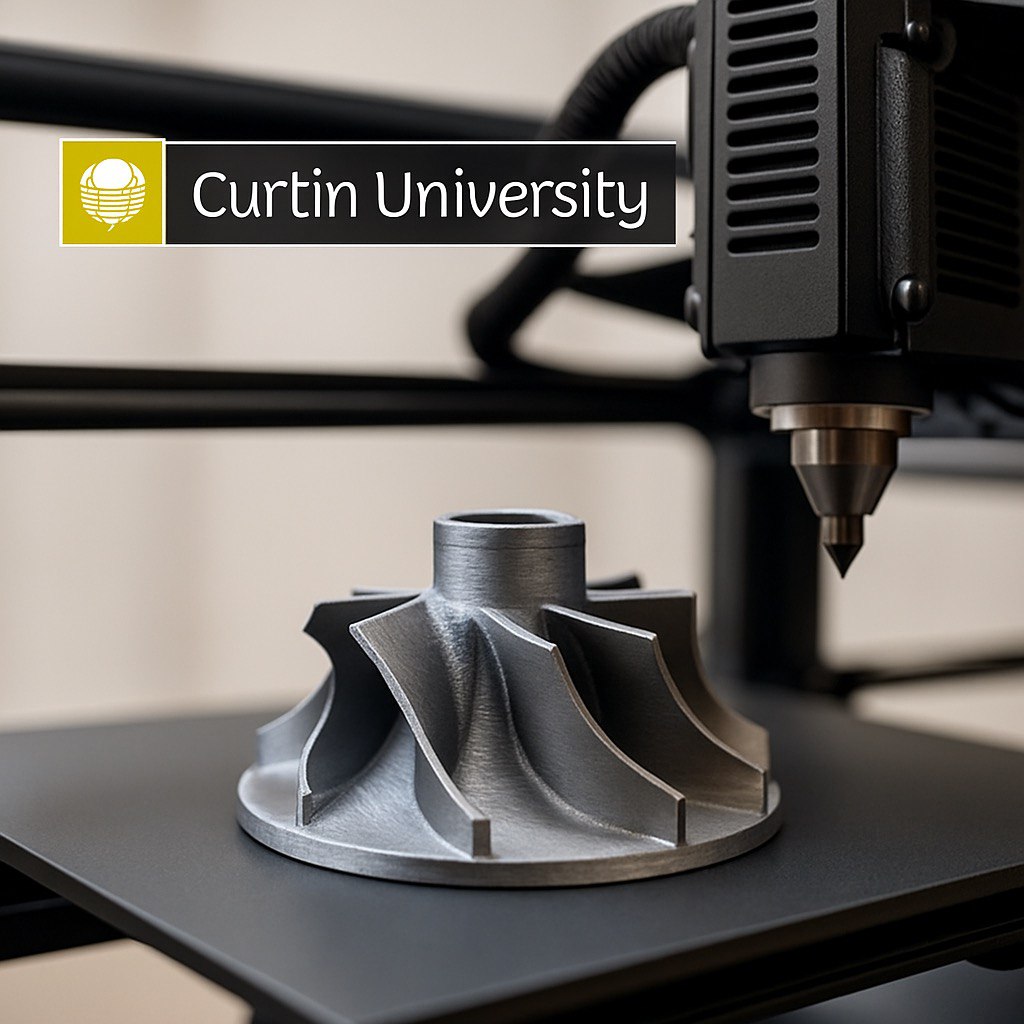

Industrial 3D printing has been instrumental in the creation of lighter, stronger, and more complex parts with reduced waste by building products layer by layer from digital designs.

Curtin university’s contributions will draw on its strengths in materials science, corrosion, and advanced manufacturing: researchers from the John de Laeter Centre and the Curtin Corrosion Centre will partner with major industry players, including shipbuilder Austal.

“Additive manufacturing is reshaping the way products are designed, built and delivered,” said Professor Melinda Fitzgerald, Curtin’s deputy vice-chancellor research. “Curtin is proud to help drive research that will advance Australia’s sovereign manufacturing capability.”

Dr Karl Davidson, Associate Professor Zakaria Quadir, Associate Professor Kod Pojtanabuntoeng, and Professor Vladimir Golovanevskiy, will be the leading researchers supervising Curtin’s involvement.

“Additive manufacturing is poised to transform supply chains, increase efficiency and reduce waste,” said Dr Davidson. “Our teams will develop stronger, lighter, and more sustainable materials for sectors like defence and marine engineering.”

The university’s advanced facilities and large-scale 3D printing platforms will also support innovation in mining, agriculture, and marine applications.