Faber Navalis, an application-ready system developed by the Dutch company CEAD B.V., is bringing large-format 3D printing to the maritime sector with the 100% automated production of full-scale, one-piece boat hulls, as reported by CompositesWorld.

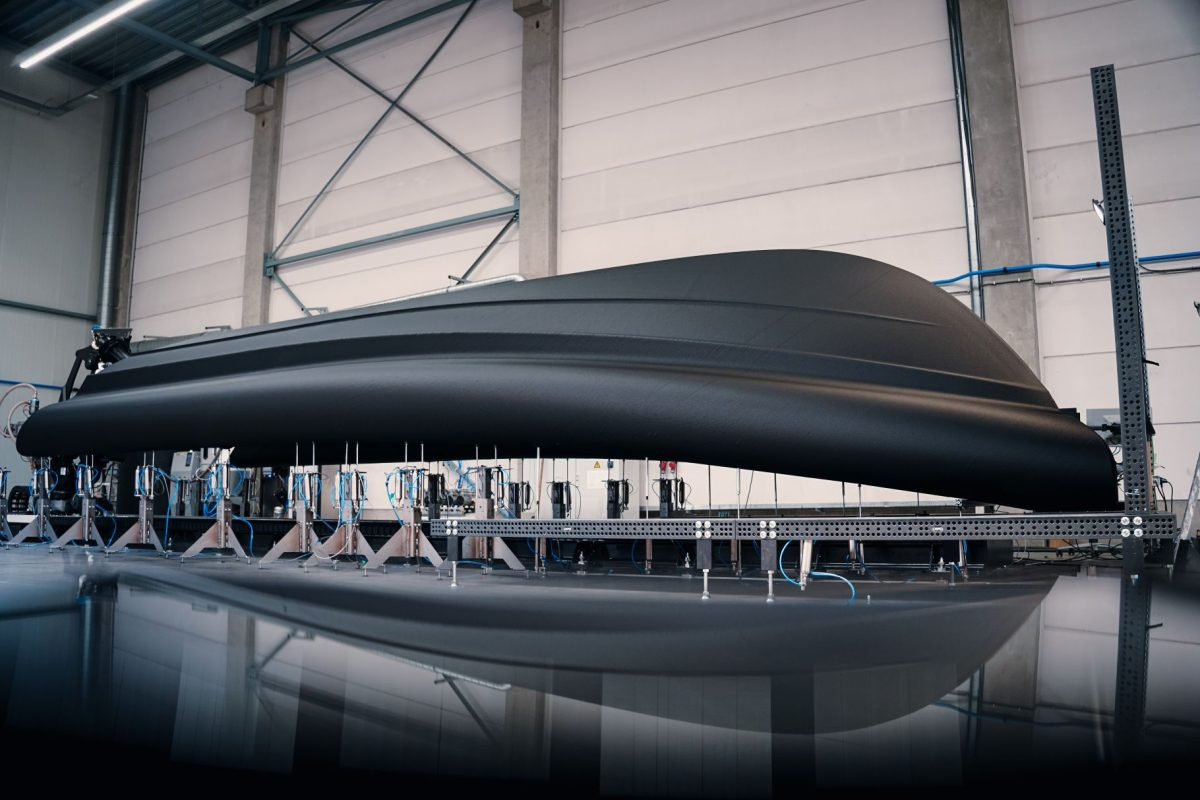

The system allows for uninterrupted, fully automated printing of maritime hull structures, with no need for segmentation, assembly or alignment. Designed for industrial and defense-grade applications, Faber Navalis integrates software, fiber-reinforced materials, and quality control into a closed-loop production process.

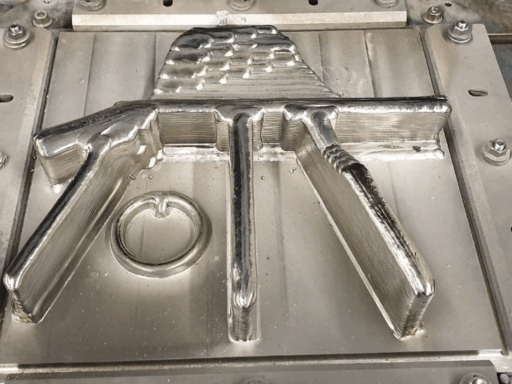

Design and manufacturing process at the core of the solution is developed in collaboration with Adaxis and is completely Faber Navalis-driven. This workflow supports efficient preparation of hull geometries with integrated internal reinforcements, including bulkheads, stringers, and stiffeners. The process aims to embed structural features directly into the printed hull, instead of adding them later.

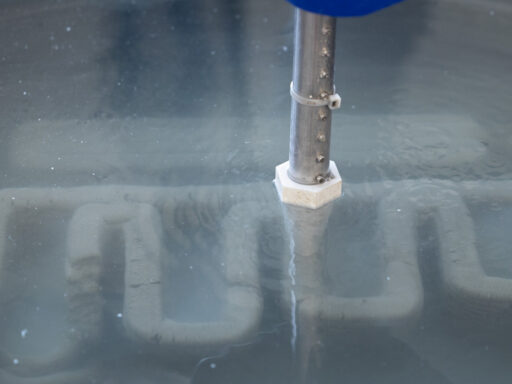

Quality assurance is an essential part of the workflow. CEAD’s data-logging platform provides process monitoring in real time, as well as quality control and fleet management. In turn, glass fiber-reinforced HDPro materials help meet performance requirements for demanding marine environments.

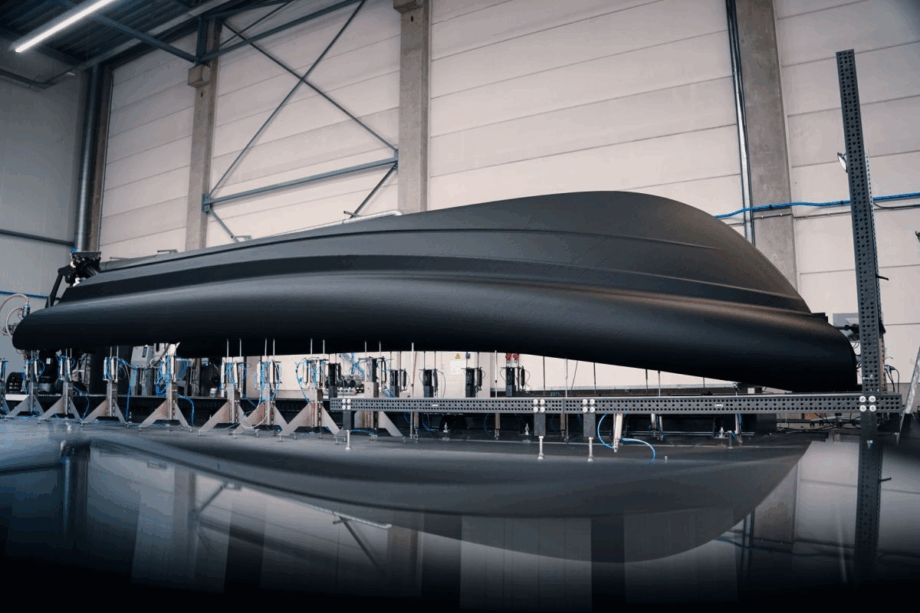

This approach enables CEAD to produce hulls up to 12 meters long and 4 meters wide in a single print. Target applications range from unmanned surface vehicles (USVs), rigid inflatable boats (RIBs), and workboats to pontoons, work platforms, and crew tenders.

Luxury yachts are not the primary focus of the project. “The process to produce yachts have different requirements in term of finishing, etc. from industrial and defense boats, therefore it is not the focus of the Faber Navalis,” said Andrea Baldolini, head of sales at CEAD Group. According to Baldolini, “using large-format 3D printing technologies can add value for patterns, tooling and interior end parts used to produce these kinds of vessels.”

Faber Navalis has already been demoed in collaboration with the Royal Dutch Navy’s Expertise Center of Additive Manufacturing, while producing a 12-meter RIB-style vessel – a tangible example of how automated 3D printing revolutionizes maritime manufacturing.