HII’s Newport News Shipbuilding (NNS) division has placed a second order for the Nikon SLM Solutions NXG 600E system, advancing the use of large-format metal 3D printing for U.S. Navy shipbuilding and the Maritime Industrial Base. The order follows an earlier acquisition announcement and reinforces HII’s long-term strategy to integrate additive manufacturing into critical naval production workflows.

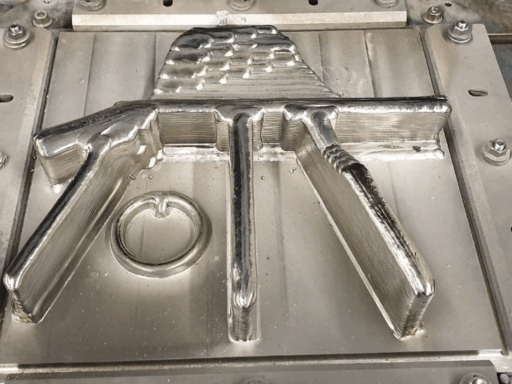

The NXG 600E is a laser powder bed fusion (L-PBF) system designed to produce large, complex metal components with high precision. With this second system, HII expands its capability to manufacture parts that have conventionally relied on large castings, often resulting in longer lead times and limited supplier availability.

The collaboration is focused on the development of additive manufacturing processes for Nickel Aluminum Bronze (NiAlBr), a corrosion-resistant alloy widely used in naval applications such as propellers and seawater systems. Working closely with HII, Nikon SLM Solutions will support parameter development and process maturation to enable repeatable L-PBF production of NiAlBr components within U.S.-based supply chains.

“This second NXG 600E order reflects HII’s leadership and long-term commitment to advancing the maritime industrial base through additive manufacturing,” Hamid Zarringhalam, CEO of Nikon Advanced Manufacturing and Chairman of the Board of Nikon SLM Solutions, said in a press release. According to Zarringhalam, expanding critical materials such as Nickel Aluminum Bronze is essential to moving metal additive manufacturing “from isolated applications to a repeatable, industrial capability.”

The additional NXG 600E system strengthens HII’s ability to produce large, mission-critical components at scale. As additive manufacturing becomes more deeply embedded in naval production, investments like this guarantee more flexible, resilient, and digitally driven shipbuilding.