At Airbus, the team is experimenting with some of the most highly stressed parts of an aircraft, growing them layer by layer from a spool of wire. This is becoming possible through a titanium 3D printing process known as wire-Directed Energy Deposition (w-DED).

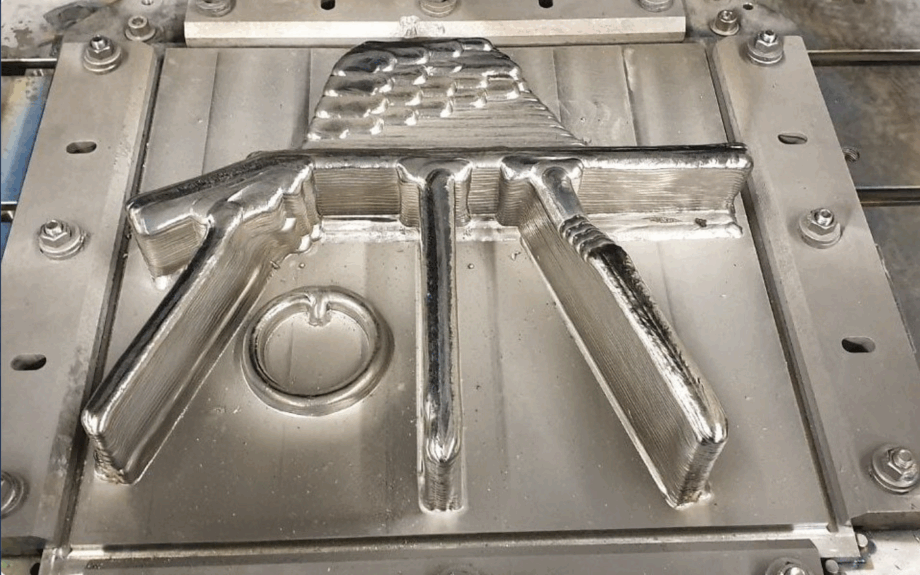

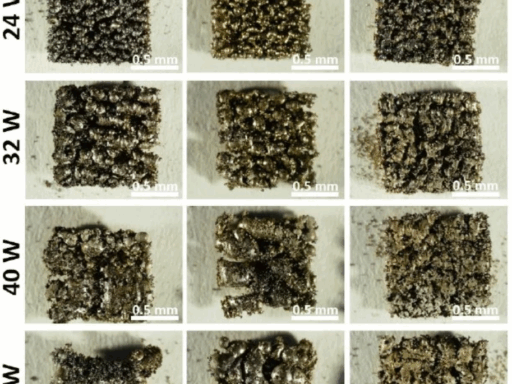

While in conventional subtractive manufacturing, parts are machined from a solid plate or forged billets, w-DED builds components additively. A multi-axis robotic arm feeds titanium wire into a focused energy source, such as plasma, laser, or electron beam, melting and depositing material precisely where needed. Guided by a digital 3D model, the process creates a “near net shaped” blank that requires only minimal final machining.

According to Airbus engineers, “w-DED allows us to move from carving metal away to growing parts intelligently. That shift changes how we think about size, waste, and design freedom.” Metal 3D printing has been used in aerospace for around a decade, but it has largely been limited to small parts produced with powder-bed systems. w-DED breaks that barrier, allowing Airbus to produce structural titanium components up to seven meters long at deposition rates of several kilograms per hour, which is an order-of-magnitude jump over earlier methods.

The benefits extend beyond scale. Titanium is prized in aircraft for its strength, lightness, and compatibility with carbon fibre composites, but it is also costly. Traditional forging can waste up to 95% of the original material, measured by the so-called buy-to-fly ratio. With w-DED, most of that waste is avoided from the outset. “Growing parts close to their final shape means we’re no longer recycling the majority of what we buy,” said engineers.

Airbus has already begun serial integration of its largest w-DED parts into the A350 Cargo Door Surround. Looking ahead, the technology enables components to be “designed for DED” – printed as single, optimized pieces rather than assembled from many parts. As Airbus and its partners continue testing energy sources and production strategies, w-DED provides an innovative manufacturing tool and serves as a foundation for the next-gen 3D designed aircraft.