Nivalon Medical Technologies Inc. has launched the world’s first fully patient-specific spinal implant that is entirely metal-free. Designed by artificial intelligence, the device is manufactured using next-gen ceramic 3D printing.

The implant is made of a combination of zirconia-toughened alumina (ZTA), a bone-mimicking ceramic material, and a flexible elastomeric core engineered for native-like spinal motion. While conventional metal implants come in fixed sizes, Nivalon’s device is digitally designed from each patient’s CT data – which makes it possible to tailor it to individual anatomy and biomechanics when 3D printing.

“I realized the problem wasn’t the surgeons – it was the implants,” Todd Hodrinsky, Nivalon’s Co-Founder and CEO, said in a press release. “We were trying to treat a living biological structure with industrial metal hardware that was never designed to behave like bone or properly follow natural spinal motion.”

Pre-clinical testing was conducted independently at the University of South Florida (USF) and the University of Connecticut Institute of Materials Science (UConn IMS). At USF, the Dynamic Investigation of Spine Characteristics (DISC) simulator was used to evaluate EvoFlex™ implants, applying physiologic spinal loading across six degrees of freedom. Results demonstrated stiffness curves and motion profiles closely replicating natural human spinal behavior, showing true motion preservation rather than simple mechanical movement.

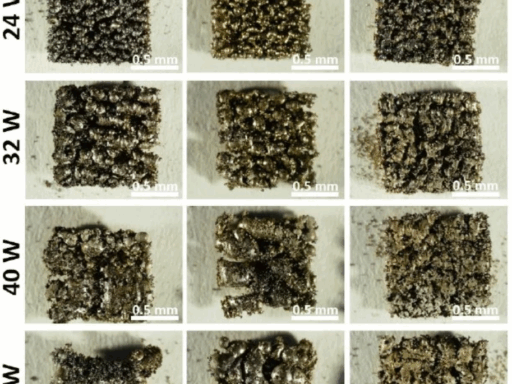

At UConn IMS, compression testing demonstrated load resistance up to 14.6 kN – approximately 1,490 kg – and shear testing confirmed strong interface integrity and controlled, progressive failure behavior. Simulated body fluid immersion and SEM-EDX analysis then showed uniform mineral deposition on the ceramic surface, supporting bone-like biological interaction and long-term osseointegration potential.

The implants were manufactured in collaboration with the Youngstown Business Incubator, using XJet’s NanoParticle Jetting™ ceramic 3D printing technology. SEM analysis confirmed the creation of a new microstructural class of biocompatible, load-bearing ceramic – now known as an industry first for a fully ceramic spinal implant produced with scalable methods.

“This is more than a technical achievement – it’s personal,” said Hodrinsky. “The endplates for my own spine are now complete.” First-in-human procedures are scheduled for 2026, marking the transition from research into clinical manufacturing and regulatory trials.