Summary (direct answer)

A resin 3D printer is a vat photopolymerization system that forms structures by curing liquid photopolymer resin with ultraviolet (UV) light. [2] In consumer and professional contexts, “resin 3D printer” commonly refers to stereolithography (SLA) (laser-scanned), digital light processing (DLP) (projected), and masked SLA (MSLA) (LCD-masked) variants. High-detail 3D prints are enabled by thin layer heights and fine optical sampling, such as 405 nm light engines and small pixel or spot dimensions. [2][3][4]

Definition and Scope (what “resin 3D printer” covers)

Vat photopolymerization is the umbrella family for resin printing processes that cure a liquid photopolymer resin with ultraviolet light to build parts layer by layer. [2] In practice, the term is used for multiple exposure architectures that share common workflow elements: a resin vat, an exposure system, Z-axis motion for layer stacking, and post-processing steps such as wash and cure (solvent washing followed by UV curing).

In consumer usage, “resin printer” is often shorthand spanning laser-based SLA systems and image-based systems (DLP and MSLA). A well-documented laser-SLA reference point is the Formlabs Form 2, which specifies SLA technology and a 405 nm laser source. [4] This breadth in meaning matters because vendors may report different “resolution,” “accuracy,” and throughput metrics depending on whether the exposure is a scanned laser spot, a projected image, or an LCD-masked image.

Historical Background (origin, inventor, early patents)

Stereolithography is closely associated with early patent literature describing the formation of three-dimensional objects from successive layers of cured resin. US Patent US4575330A lists inventor Charles W. Hull, a priority date of 1984-08-08, and a publication date of 1986-03-11. [1] Within modern vat photopolymerization practice, these early concepts are recognizable in today’s layer-by-layer exposure, Z-axis indexing, and the requirement to separate each newly cured layer from a boundary surface before the next layer is formed.

Technical Principles (how resin printing works)

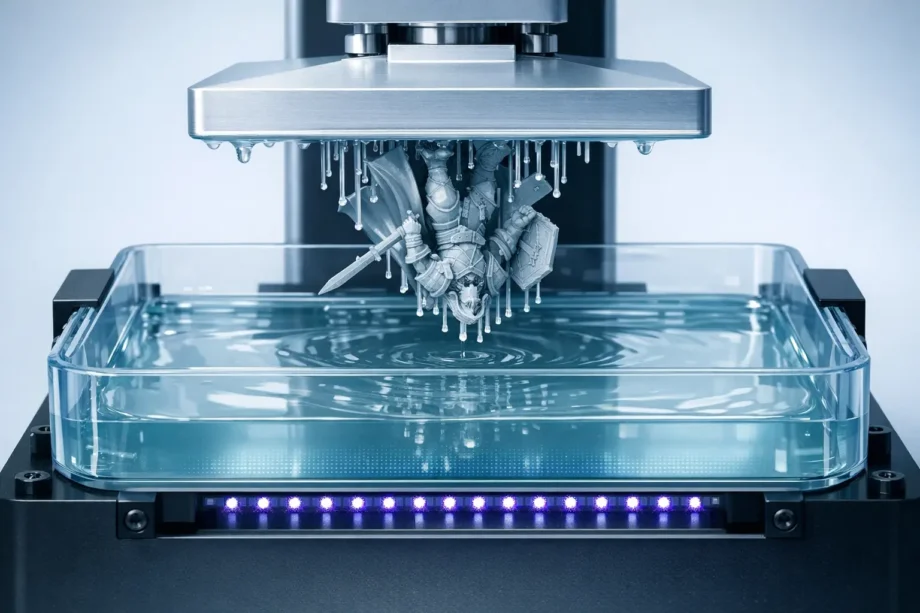

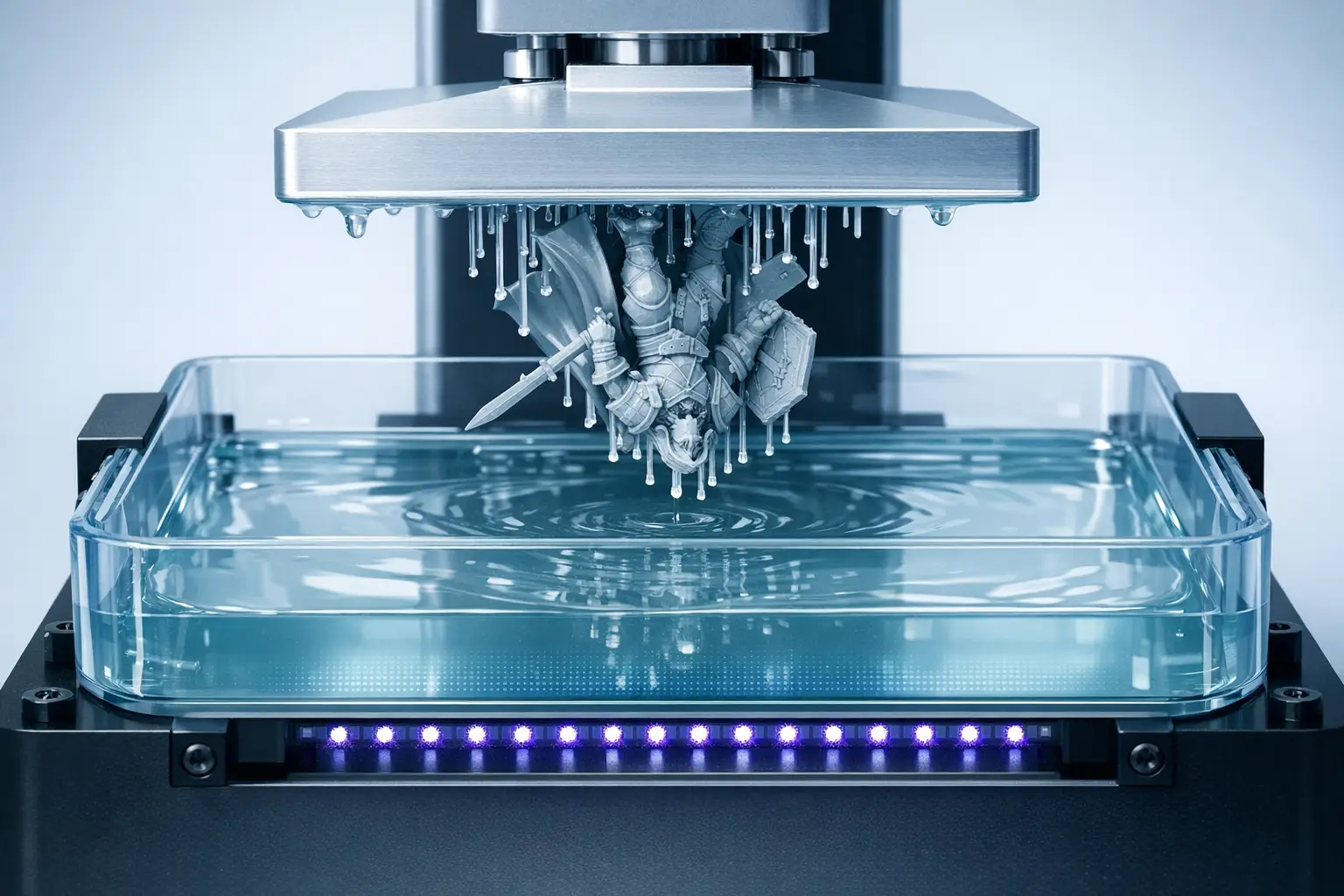

In vat photopolymerization, a build platform is positioned relative to a vat of liquid photopolymer resin, and UV exposure selectively cures resin into a solid crosslinked polymer for a single layer. [2] After exposure, the Z axis moves to create a gap for fresh resin to flow under (or over) the part, and the next layer is exposed. In many desktop machines, a peel or separation step is required to release the newly cured layer from a nonstick boundary surface, typically a peel / release film (FEP / PFA / ACF) at the vat bottom, before the subsequent layer can be formed.

The need for supports is primarily geometric: overhangs and isolated “islands” in early layers may not be mechanically connected to the main part during exposure, so supports provide a load path during the peel cycle and prevent floating cured fragments from forming. Supports also act as thermal and mechanical stabilizers as layers accumulate, but they introduce surface marks that must be managed through orientation and post-processing. Operationally, resin printing is not only a “printing” step; exposure studies report that task-based emissions can be highest during post-processing, including IPA (isopropyl alcohol) rinsing/soaking/drying with TVOC (total volatile organic compounds) reported up to 36.8 mg/m³. [14]

Technology Variants (SLA vs DLP vs MSLA)

SLA typically scans a focused laser spot across each layer as a vector path, while DLP and MSLA expose a full layer image in one or more flashes, with the image formed by a projector (DLP) or an LCD mask in front of a UV backlight (MSLA). A representative SLA specification is a 405 nm laser on the Form 2. [4] A representative MSLA specification is a 405 nm light engine with a pixelized imaging plane, such as the Form 4, which specifies 405 nm optics and a 50 µm pixel size. [3] These differences affect how print time scales with layer area: scanned systems generally scale with path length and feature count, while image-based systems scale with the number of layers and exposure strategy for a given layer.

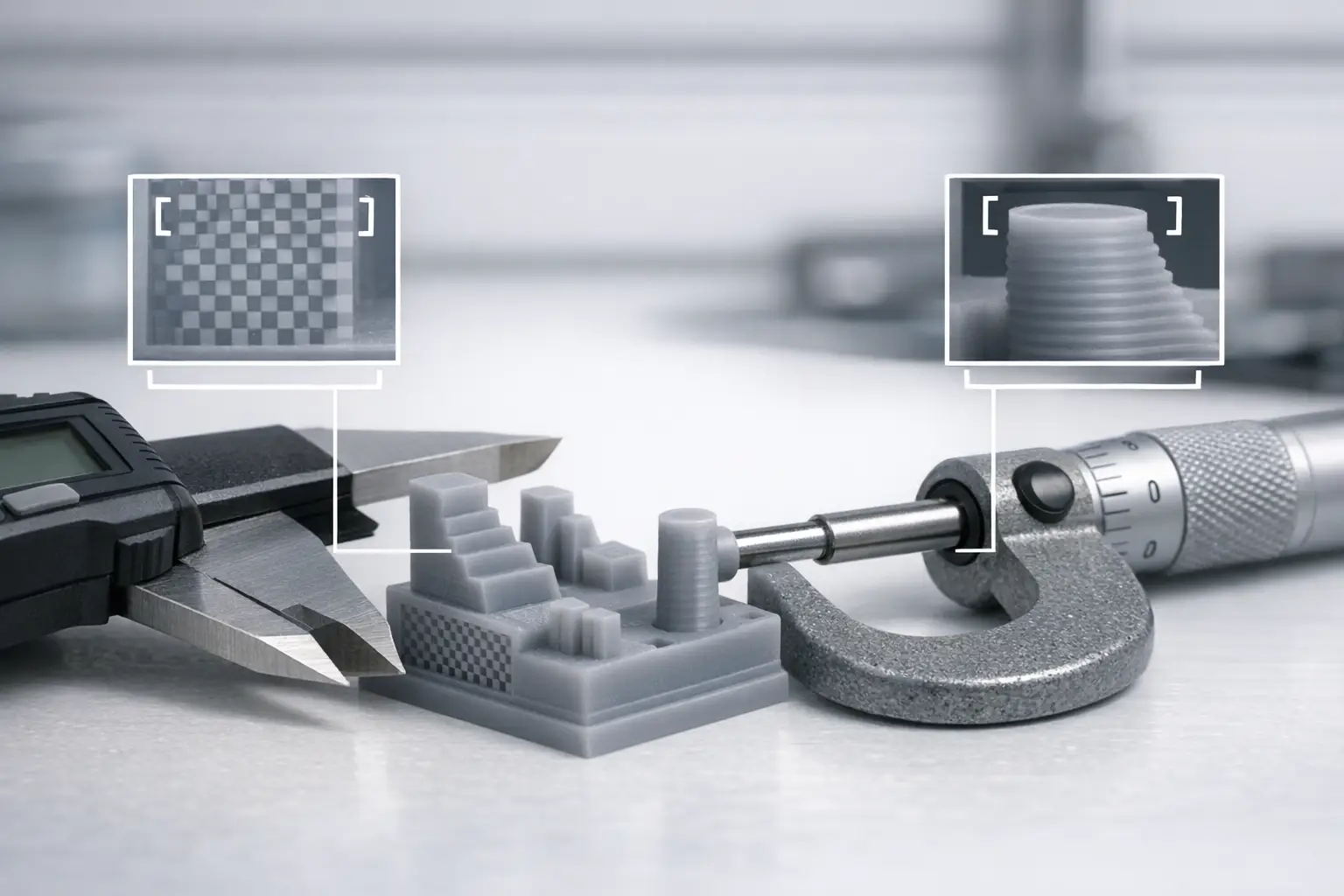

Technical Performance Metrics (what “high detail” means in specs)

“High detail” in resin 3D printing is usually presented through a mix of nominal imaging metrics (XY resolution or pixel size, or laser spot size), Z resolution (layer height), and empirical performance metrics such as dimensional tolerance. Vendors may also publish delivered optical parameters at the cure plane. For example, Formlabs reports typical XY dimensional tolerances for the Form 4 as ±0.15% (lower limit ±0.02 mm) for 1–30 mm features, ±0.2% (lower limit ±0.06 mm) for 31–80 mm, and ±0.3% (lower limit ±0.15 mm) for 81–150 mm. [3] These tolerance bands describe expected deviation in finished part dimensions under stated conditions, and they are not equivalent to the pixel size of an MSLA panel or the spot size of an SLA laser.

XY resolution is reported differently across architectures. In laser-SLA contexts, vendors may publish an “XY resolution” alongside spot size; Formlabs lists Form 3 “quick stats” including XY resolution of 25 microns and a laser spot size of 85 microns, with layer thickness 25–300 microns. [6] For the Form 2, Formlabs lists a laser spot size (FWHM) of 140 microns and layer thickness options of 25, 50, and 100 microns, alongside a 405 nm laser wavelength and 250 mW laser power. [4] Vendor reporting may also distinguish between source power and power at the print plane; Formlabs’ comparison material cites maximum laser power at the print plane of 180 mW (Form 3+) and 96 mW (Form 2), while also listing spot sizes of 85 microns (Form 3+) and 140 microns (Form 2). [5] For MSLA, “XY resolution” may be given as a pixel pitch or an “accuracy” proxy: the Form 4 lists a 50 µm pixel size, while consumer machines commonly publish anisotropic XY values such as 19 × 24 µm. [3][10]

Optics and Sampling Limits (pixels, spot size, anti-aliasing)

Pixel grids (MSLA/DLP) and spot profiles (SLA) define a sampling limit, but they do not fully determine surface quality or dimensional tolerance. LCD-based systems may use grayscale or temporal anti-aliasing to approximate edges between pixel boundaries, but these methods do not remove the underlying sampling lattice, and they interact with resin cure depth, scattering, and overcure at feature edges. Laser systems similarly involve spot overlap, scan strategy, and resin kinetics; a nominal spot size of 85 microns does not imply that every edge will resolve to that value in all orientations and geometries. [5][6]

Speed Metrics (max vs typical)

Resin printer speed is typically expressed as a vertical build rate (mm/hour) and is influenced by resin chemistry, exposure energy, peel/lift settings, and layer height. Formlabs distinguishes maximum print speed of 100 mm/hour from typical average print speed of 40 mm/hour (range 16–50 mm/hour) on the Form 4. [3] Consumer vendors may publish separate averages tied to resin types; for the Anycubic Photon Mono M5s, the manufacturer lists average printing speed of 105 mm/hr (high speed resin) and 70 mm/hr (general resin). [9]

Materials and Resin Categories (properties and constraints)

Photopolymer resin families are often grouped as standard resins (general prototyping), tough or engineering-like resins (higher impact resistance), flexible or elastic resins (lower modulus), castable resins (clean burnout behavior), and dental or biocompatible resins (application- and regulation-specific). Material choice affects required exposure energy and thus throughput; vendor speed reporting can be tied to resin selection, as illustrated by the Form 4’s maximum of 100 mm/hour and typical average of 40 mm/hour (range 16–50 mm/hour). [3] Some systems also specify an operating resin temperature window; for the Form 4, an internal resin temperature range of 25–45 °C is published in manufacturer technical specifications. [3]

End-to-End Workflow (print preparation through curing)

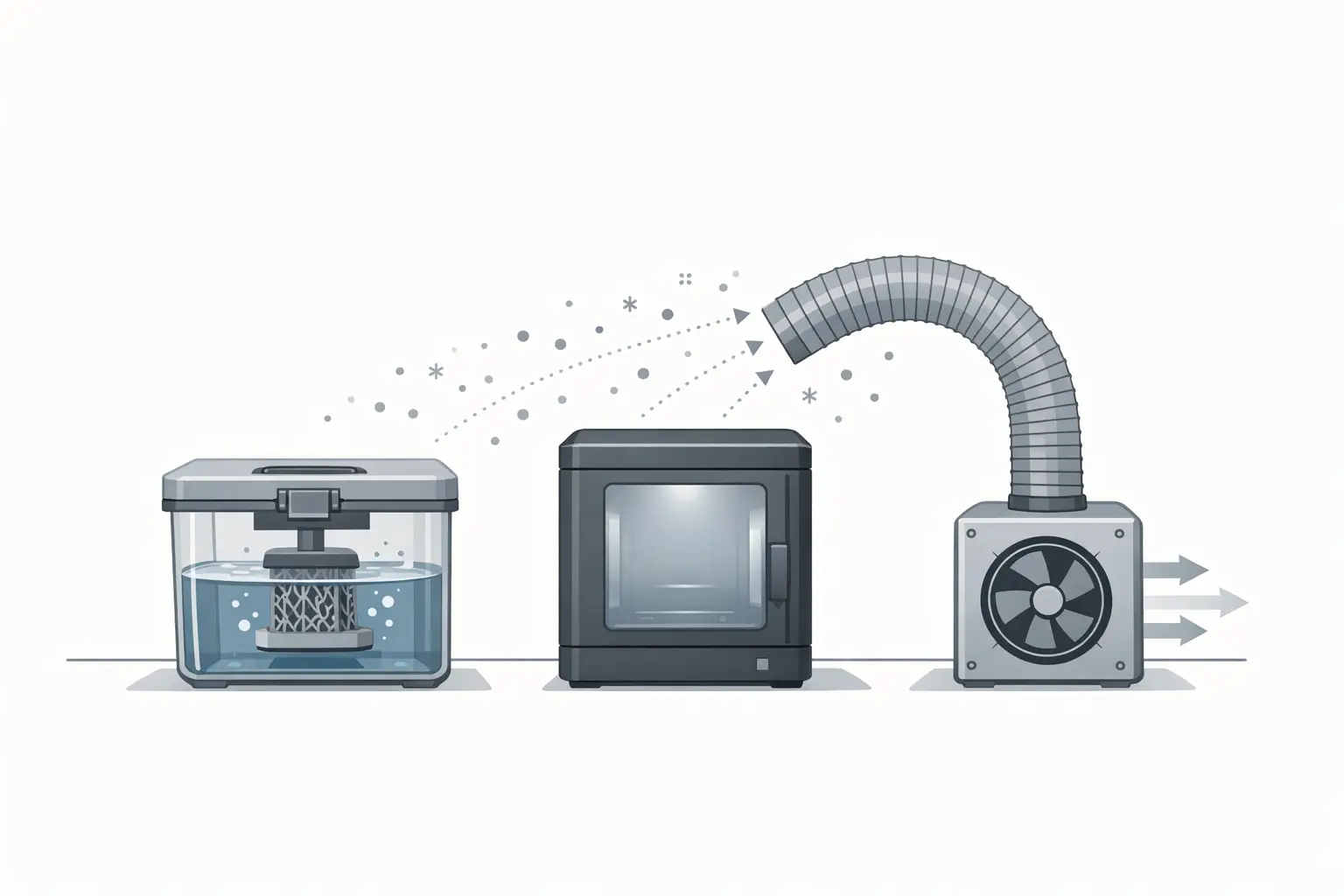

A typical resin workflow starts in the slicer: the model is oriented to reduce unsupported overhangs, critical surfaces are angled to manage layer stepping, and supports are generated to anchor islands and distribute peel loads. Slicing parameters include layer height, exposure time or energy per layer, lift distance/speed, and compensation features that vary by machine and resin. Vendor specifications illustrate the parameter ranges users must map onto a workflow: the Anycubic Photon Mono M5s publishes average printing speeds of 105 mm/hr (high speed resin) and 70 mm/hr (general resin), and a layer thickness range of 0.01–0.15 mm. [9]

Printing is followed by controlled draining and part removal to reduce resin carryover. Parts are then washed (often in IPA) to remove uncured resin film, dried to avoid solvent entrapment, and UV cured to complete polymerization and stabilize mechanical properties. The exposure profile of the full workflow can be dominated by post-processing rather than the in-printer exposure: a task-based study of vat photopolymerization reported TVOC levels highest during IPA rinsing/soaking/drying up to 36.8 mg/m³, compared with resin pouring/printing/recovery tasks up to 0.1 mg/m³, and curing up to 3 mg/m³. [14] Operational controls therefore extend beyond printer settings to include closed wash containers, local exhaust ventilation, and disciplined resin handling and storage.

Applications (where resin printing is used)

Resin 3D printing is used where surface finish and fine feature reproduction are prioritized, including figurines and miniatures, jewelry pattern making and master models, fit-check prototypes for small enclosures or mechanisms, and dental models and appliances that benefit from fine surface detail. These application areas are usually constrained by post-processing requirements (support removal marks and UV cure stability) and by the properties of photopolymer materials relative to thermoplastics. Claims about specific clinical accuracy or end-use certification depend on a printer–resin–process combination, and no reliable figure found for a general, cross-vendor accuracy guarantee applicable to all dental or medical uses.

Health, Safety, and Environmental Handling (non-optional)

Resin printing involves multiple potential exposure pathways: uncured resin handling, emissions during printing, solvent washing emissions, and UV curing emissions. The US Environmental Protection Agency (EPA) notes that 3D printing emissions can include VOCs and particulates, and defines ultrafine particles as 1–100 nm. [12] A peer-reviewed study focused on vat photopolymer resins reported average VOC concentrations of 41–87 µg/m³ and UFP number levels of 0.19–3.62 × 10³ number/cm³, with the majority of UFPs in the 10–45 nm range. [13] The same study reported that VOC outgassing rates from printed parts decreased by 84–96% after 28 days, from 3000–14000 µg/m²/hr to 100–1000 µg/m²/hr. [13]

Task-based measurements further emphasize that the highest short-term exposures may occur during post-processing, not during the closed printing step. In a study of vat photopolymerization tasks, maximum particle concentration reached 1200 #/cm³, and TVOC levels were reported up to 36.8 mg/m³ during IPA rinsing/soaking/drying, compared with up to 0.1 mg/m³ during resin pouring/printing/recovery and up to 3 mg/m³ during curing. [14] Guidance from safety-oriented research organizations also highlights the complexity of emissions: UL Chemical Insights describes VOC mixtures that can exceed 200 distinct species, reports that particle emissions “could reach up to one trillion particles per hour,” and notes that uncured resin can emit VOCs even when a printer is loaded and turned off. [15] Practical controls therefore focus on minimizing skin contact with uncured resin, limiting solvent vapor accumulation, and providing ventilation that is designed for the wash and cure zone as well as the printer.

Maintenance and Operating Costs (consumables and wear items)

Maintenance for resin 3D printers centers on keeping the optical path and vat boundary surface consistent: resin tanks accumulate cured debris and require filtering practices, while release films (FEP/PFA/ACF) can haze, scratch, or develop adhesion changes that increase failure probability. LCD-based MSLA systems treat the LCD as a wear component and may publish lifespan claims; the Original Prusa SL1S SPEED lists an LCD lifespan of 2000 hours, and Anycubic lists an LCD lifespan of 2000 hours for the Photon Mono M5s. [7][9] Laser-SLA systems shift wear concerns toward galvanometers and optical cleanliness; the Form 2’s published laser parameters (405 nm wavelength and 250 mW laser power) contextualize why optics contamination control and resin tank condition can affect cure consistency. [4]

Comparison Table (mandatory)

The table below compares representative resin 3D printers using only vendor-published or explicitly cited review specifications, and it separates nominal imaging metrics (pixel size, XY resolution, or spot size) from throughput metrics (mm/hr or exposure time). Where manufacturers use ambiguous terms such as “X accuracy,” the table retains that phrasing and adds a cited XY resolution from an independent technical review when available. [9][10]

| Printer | Exposure & light engine | Build volume | Detail & throughput (selected published metrics) |

|---|---|---|---|

| Formlabs Form 4 | MSLA; 405 nm; 60 LEDs; 16 mW/cm² at cure plane. [3] | 20.0 × 12.5 × 21.0 cm. [3] | 50 µm pixel size; layer thickness 25–200 µm; max speed 100 mm/hour; typical average 40 mm/hour (range 16–50 mm/hour). [3] |

| Formlabs Form 2 | SLA; 405 nm; 250 mW laser. [4] | 145 × 145 × 175 mm. [4] | Layer thickness 25, 50, 100 microns; laser spot size (FWHM) 140 microns. [4] |

| Original Prusa SL1S SPEED | MSLA; LCD 5.96″ at 2560 × 1620. [7] | 127 × 80 × 150 mm. [7] | Layer exposure time 1.4–2.5 s; supported layer heights 0.025–0.1 mm; LCD lifespan 2000 hours. [7] |

| Anycubic Photon Mono M5s | MSLA; 10.1″ monochrome 12K (11520 × 5120). [9] | Print dimensions 200 × 218 × 123 mm (axis order as published). [9] | “X accuracy” 19 microns; average printing speed 105 mm/hr (high speed resin) and 70 mm/hr (general resin); LCD lifespan 2000 hours; X/Y axis resolution 19 × 24 microns. [9][10] |

| ELEGOO Saturn 4 Ultra (12K) | MSLA; 405 nm light source; field uniformity 92%. [11] | 218.88 × 122.88 × 220 mm. [11] | Resolution 11520 × 5120; XY resolution 19 × 24 μm; astigmatism coefficient 0.5%; angle deviation below 5°. [11] |

A second comparison table summarizes technology types at a qualitative level, because many practical differences depend on implementation (optics, resin, peel mechanics) rather than the label alone.

| Technology type | Exposure mechanism | Detail drivers (typical) | Operational notes (typical) |

|---|---|---|---|

| SLA | Scanned laser spot (vector path) | Spot size, scan strategy, resin kinetics | Build time can scale with feature/path complexity; optics cleanliness can be critical. |

| DLP | Projected image (micromirror array) | Projected pixel size, lens modulation transfer, uniformity | Full-layer exposure can stabilize layer time; projector optics and uniformity shape edge fidelity. |

| MSLA (LCD) | UV backlight with LCD mask | Pixel size, panel quality, light uniformity | Full-layer exposure; LCD and release film are wear components; anti-aliasing is implementation-dependent. |

Selection Checklist (what to verify before buying)

A resin 3D printer selection should separate nominal XY sampling from dimensional tolerance and from workflow-driven quality limits: published tolerances such as ±0.15% (lower limit ±0.02 mm) for 1–30 mm features illustrate how “accuracy” can be framed independently of pixel size. [3] Verify layer height support, resin ecosystem constraints, peel/release film availability, and the footprint for wash and cure; post-processing emissions can dominate exposure, with TVOC reported up to 36.8 mg/m³ during IPA rinsing/soaking/drying. [14]

References and Further Reading

Primary documents and standards-adjacent definitions are useful for anchoring terminology and process scope, including US4575330A for early stereolithography concepts and NIST’s definition of vat photopolymerization as UV curing of liquid photopolymer resin. [1][2]

For safety validation, peer-reviewed exposure and emissions studies provide quantitative bounds that are often absent from product literature, including reported VOC and ultrafine particle measurements for vat photopolymer resins and task-based comparisons showing higher TVOC during IPA washing tasks. [13][14]

Q&A (FAQ)

1) What is a resin 3D printer (vat photopolymerization) and how does it work?

A resin 3D printer is a vat photopolymerization machine that forms structures by curing liquid photopolymer resin with ultraviolet light. [2] In operation, the printer selectively exposes a thin layer of resin, solidifying that layer; then the Z axis repositions so fresh resin can recoat and the next layer can be cured. Repetition of exposure, separation from the release surface, and Z-axis indexing produces the final part geometry. [2]

2) SLA printer vs MSLA (LCD) resin printer — what is the difference in practice?

In an SLA printer, a laser scans the layer as a path; the Form 2, for example, specifies SLA with a 405 nm laser. [4] In an MSLA printer, the layer image is formed through a pixel grid, such as the Form 4’s 405 nm system with a specified 50 µm pixel size. [3] Practically, this changes how exposure is parameterized (scan paths versus layer images), how layer time scales with area, and which wear components are emphasized (optics versus LCD and release film).

3) What specifications determine high detail prints on a resin 3D printer?

High detail is constrained by XY sampling and Z layer height, plus the resin’s cure behavior and the printer’s mechanics. For laser-SLA, published metrics include spot size and XY resolution; Formlabs reports an 85 micron spot size and 25 micron XY resolution for Form 3 quick stats. [6] For MSLA, vendors often publish XY resolution or pixel size; for example, the Form 4 specifies a 50 µm pixel size, while consumer MSLA machines may publish 19 × 24 µm XY resolution. [3][11]

4) What is a realistic dimensional accuracy expectation for resin printing? (expert-level)

Dimensional accuracy is better approached via published tolerance bands than via nominal XY pixel size alone. For the Form 4, Formlabs reports typical XY dimensional tolerances of ±0.15% (lower limit ±0.02 mm) for 1–30 mm features, ±0.2% (lower limit ±0.06 mm) for 31–80 mm, and ±0.3% (lower limit ±0.15 mm) for 81–150 mm. [3] These values incorporate process effects (resin shrinkage, overcure, peel mechanics), so a printer with small pixels can still produce larger deviations if the full process is not controlled.

5) Do resin printers emit VOCs, and when is exposure highest — during printing or post-processing? (expert-level)

Measurements indicate that both printing and post-processing can emit VOCs and particles, but task-based exposure can peak during post-processing. A study of vat photopolymer resins reported average VOC concentrations of 41–87 µg/m³ and UFP levels of 0.19–3.62 × 10³ number/cm³, with most UFPs at 10–45 nm. [13] In task-based measurements, TVOC was highest during IPA rinsing/soaking/drying up to 36.8 mg/m³, compared with resin pouring/printing/recovery tasks up to 0.1 mg/m³. [14]

6) What is a typical layer thickness range for SLA and MSLA printers?

Published layer thickness ranges vary by machine and resin. For the Form 4 (MSLA), Formlabs specifies 25–200 µm layer thickness. [3] For laser-SLA, Formlabs lists Form 3 quick stats with 25–300 microns and the Form 2 with discrete layer thickness settings of 25, 50, and 100 microns. [6][4] For a consumer MSLA example, Anycubic lists a layer thickness range of 0.01–0.15 mm for the Photon Mono M5s. [9]

Sources

- US4575330A — Apparatus for production of three-dimensional objects by stereolithography

- NIST — Vat Photopolymerization

- Formlabs — Form 4 Technical Specifications

- Formlabs — Form 2 Technical Specifications

- Formlabs Blog — Form 3 vs Form 2 3D Printer Comparison

- Formlabs Blog — Introducing Form 3 and Form 3L (Low Force Stereolithography)

- Prusa3D Blog — Introducing SL1S SPEED

- Prusa Knowledge Base — Original Prusa SL1 vs SL1S SPEED

- Anycubic Store — Photon Mono M5s

- Tom’s Hardware — Anycubic Photon Mono M5s Review

- ELEGOO — Saturn 4 Ultra

- EPA — EPA Researchers Continue Study of Emissions from 3D Printers

- PubMed — VOCs and UFPs from vat photopolymer resins (Index record)

- PubMed — Task-based exposure during vat photopolymerization incl. IPA washing (Index record)

- UL Chemical Insights — 3D Printing