A new study suggests future Mars missions could slash costs by using the planet’s own atmosphere as a key ingredient in metal 3D printing, as reported by Universe Today. In their paper, the University of Arkansas scientists Zane Mebruer and Wan Shou examine how selective laser melting (SLM, a major technique for producing 316L stainless-steel parts) behaves when shielded not by costly imported Argon, but by Mars’ naturally abundant carbon dioxide.

On Earth, SLM requires an inert “shield gas” to push out oxygen, which otherwise “actively oxidizes the material being printed,” making parts brittle. “Argon is the gold standard,” the authors write, but it is expensive and almost absent on Mars. Importing it would be a significant logistical challenge.

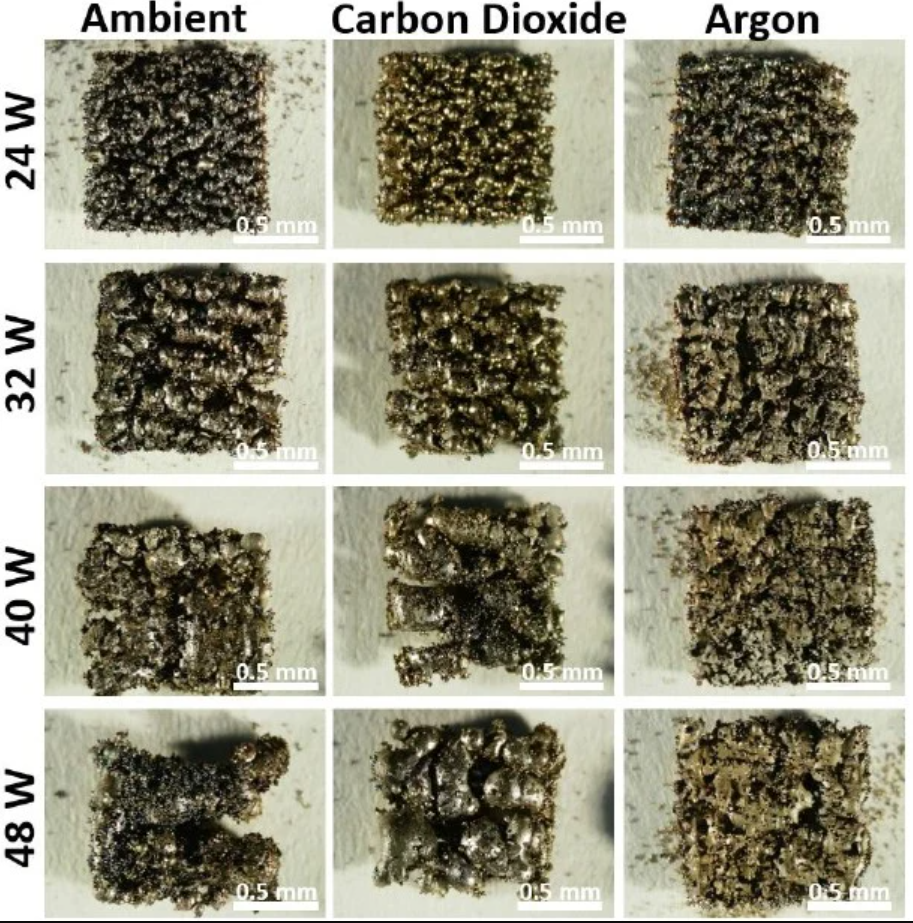

The researchers tested SLM prints under three conditions: Argon, CO₂, and ambient air. The findings were unexpectedly promising. While Argon still delivered the best results, achieving about 98% area retention in one solid-layer test, CO₂ reached a respectable 85%, making it viable for “a wide variety of non-critical infrastructure parts,” such as hinges or handles. As expected by scientists, ambient air performed poorly, with less than 50% retention and essentially unusable output.

Why does CO₂ work at all? As the paper explains, at SLM’s extreme temperatures, carbon dioxide dissociates, releasing oxygen. However, its partial pressure of oxygen remains lower than Earth’s nitrogen-rich atmosphere, meaning less oxidative damage reaches the melt pool. “Even Argon-printed parts contain some oxygen,” the authors write, but CO₂ samples had only about 1.6× more, still far below the levels that ruin print quality.

Beyond Mars, the findings hint at cost-cutting opportunities for terrestrial manufacturers. But for astronauts, aesthetics is not as important as functionality. A printer running on the thin air “that would otherwise be trying to kill them” could become a key element of on-site resource utilization. A good reason to start thinking about sustainable Martian settlement!