Summary

Artec Micro II and Artec Point are two leading solutions for high-precision jewelry 3D scanning, each tailored to distinct needs. The Artec Micro II excels in metrology-grade applications, offering 5-micron point accuracy and 2-micron repeatability, making it ideal for capturing the finest jewelry details. In contrast, the Artec Point delivers impressive 0.02 mm (20-micron) accuracy in a portable, handheld format, providing flexibility for a wider range of jewelry and small artifact scanning scenarios.

Historical background

The original Artec Micro, introduced in 2019, marked Artec 3D’s entry into desktop 3D scanning dedicated to small-object metrology, boasting 10-micron accuracy at launch. Headquartered in Luxembourg and with research and development in the United States, Artec 3D has since evolved the platform into the Micro II, raising standards in jewelry 3D scanning. [1]

Technical overview

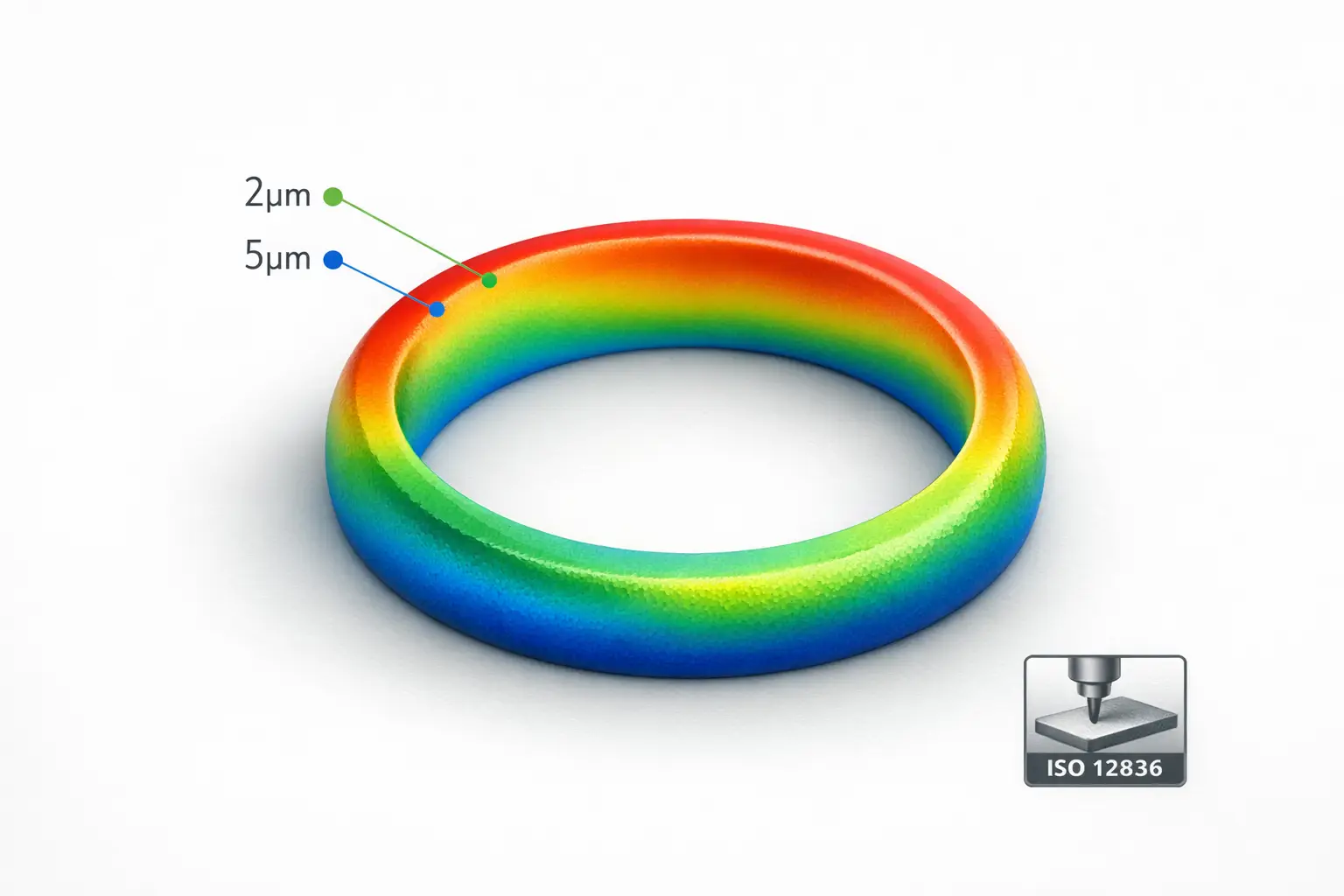

Both Artec Micro II and Artec Point employ structured-light 3D scanning — a technology that projects precise patterns onto the object and measures deformation to calculate surface geometry. The Artec Micro II, a desktop scanner, targets extreme accuracy: point accuracy down to 5 microns (0.005 mm) and repeatability of 2 microns, both certified under ISO 12836 metrology standards. The system accommodates objects up to 20 × 20 × 15 cm, making it ideal for rings, pendants, watches, and small medallions. Its rapid data acquisition of 1 million points per second ensures efficient digitization even of filigree details. [2][3][4][5]

By contrast, the Artec Point is a lightweight, handheld scanner built for convenience without sacrificing much in precision. It achieves 20-micron (0.02 mm) accuracy and resolution, making it suitable for jewelry capturing but also effective with larger items or those requiring operation away from the desktop environment. The main distinction lies in the Micro II’s fixed configuration and higher repeatability versus the Point’s portability. [6]

Performance Metrics:

- 5-micron accuracy (Micro II)

- 2-micron repeatability (Micro II)

- ISO 12836 certification (Micro II)

- 1,000,000 points/second scan speed (Micro II)

- 20-micron accuracy/resolution (Point)

- Desktop vs. portable operation

Practical Considerations for Jewelry Scanning:

- Choice depends on object size and detail needed

- Desktop provides best repeatability for high-value pieces

- Handheld suited for fieldwork, larger or irregular items

- Consider workflow integration and operator skill

Applications for jewelry

In jewelry design and manufacturing, the Artec Micro II allows precise reverse engineering and replication of intricate forms such as antique rings, gemstone settings, and filigree work. Its high repeatability is crucial for quality inspection and documentation, ensuring even minute imperfections are captured and analyzed. The Micro II is a top choice when precision is paramount, such as in producing custom mounts or restoring historical pieces.

Conversely, the Artec Point is especially useful for jewelers and appraisers working outside studio environments. Its accuracy is sufficient for many design and sizing applications, especially for larger pieces or those with rough, matte, or varied surfaces. Using both scanners in tandem offers maximum flexibility — precise, fixed scanning in-house with Micro II, and mobile capability for less controlled conditions. [7]

Research and updates

The Artec Micro II is currently Artec 3D’s latest desktop scanner and has been consistently ranked as the leading professional jewelry 3D scanner, particularly for its unmatched 5-micron point accuracy and metrology certification. According to independent industry reviews and use-case demonstrations, it sets the standard for fine-detail jewelry scanning. No peer-reviewed comparisons yet exist, so manufacturer specifications and professional reviews guide best practice. [7]

Q&A (FAQ)

- What makes the Artec Micro II the best 3D scanner for jewelry?

Its 5-micron point accuracy, repeatability, and ISO certification yield unmatched detail for jewelry. [2] - Is Artec Point good for jewelry scanning?

Yes — its 20-micron accuracy is suitable for high-detail scans, especially in non-laboratory settings. [6] - What is a metrology-grade jewelry scanner?

Devices like Micro II provide dimensional accuracy and repeatability meeting industrial standards such as ISO 12836. - Is the Artec Micro II a structured-light jewelry scanner?

Yes, it uses blue LED structured-light for high-resolution surface capture. - Can you integrate photogrammetry with Artec Micro II scans?

While photogrammetry offers color and scale context, the Micro II’s precision is vastly higher; hybrid workflows require specialized alignment software. - Why is ISO 12836 certification important for jewelry scanners?

It verifies that accuracy claims meet rigorous, standardized tests, which is vital for critical quality assurance.

Sources

- Artec 3D — Wikipedia (français)

- Artec Micro II portable 3D scanner — Official specs

- Artec Micro II accuracy and repeatability

- Artec Micro II ISO12836 certification

- Artec Micro II data acquisition speed

- Artec Point scanner accuracy and specs

- Best Jewelry 3D Scanners in 2024 — 3DSourced industry review