A centuries-old instrument is getting a high-tech revamp with the help of 3D printing and carbon fiber. Forte3D, co-founded by Alfred Goodrich and Yale biomedical engineering senior Elijah Lee, has reimagined the cello from the ground up using modern materials and digital design. The team aimed to make a durable, affordable, and accessible instrument while fully maintaining sound quality.

“For centuries, the cello has been essentially unchanged,” Lee said. “We asked what it would look like if we designed it today, using the tools engineers have now.”

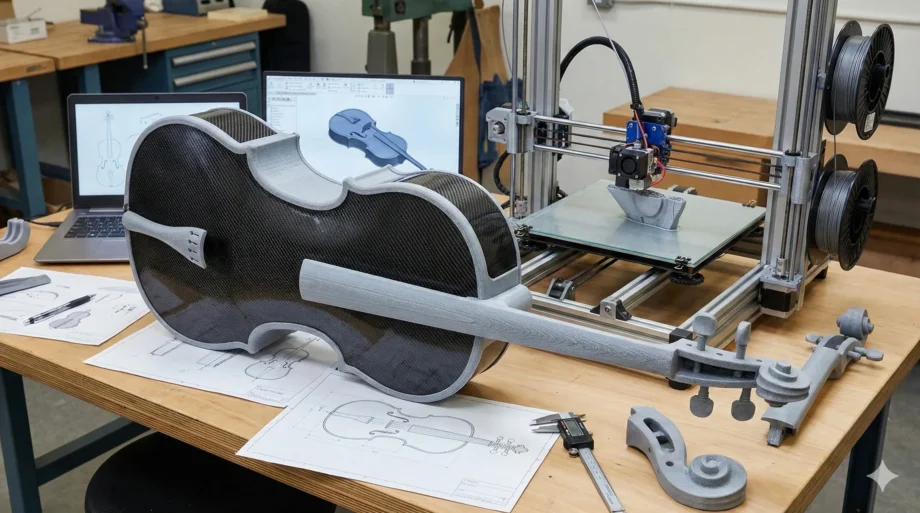

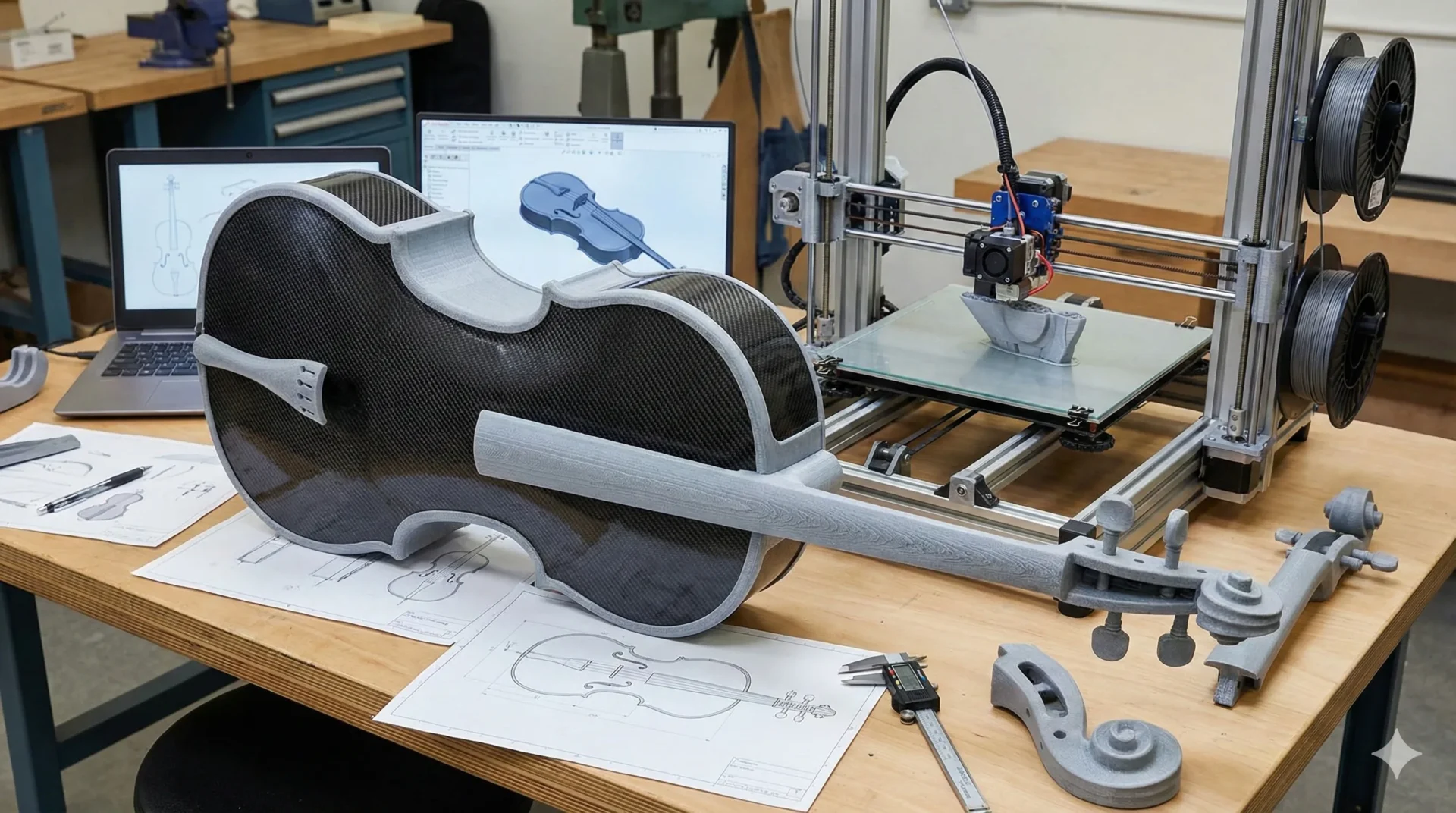

The price of traditional wooden cellos can be over $5,000, and the instrument is highly sensitive to temperature, humidity, and travel. Forte3D offered a solution replacing carved wood with flat carbon-fiber panels for the top and back. In turn, the ribs, neck, and scroll are polymer 3D-printed. Key acoustic elements, including the sound post, fingerboard, and bridge, remain conventional for tonal authenticity.

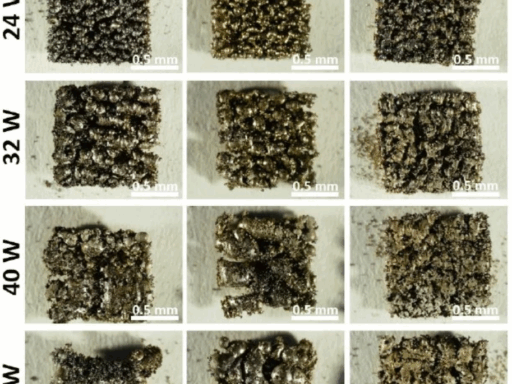

“Because we’re using our own designs, we can really dial in the acoustics,” Lee added. CAD modeling and rapid prototyping enabled the team to adjust thickness, shape, and materials at a consistent level that’s impossible with wood.

The team extended the engineering challenge beyond the cello itself: out of Goodrich’s home, they built a custom, large-format 3D printer that can produce cello- and violin-sized components. Six years and hundreds of design iterations later, Forte3D appeared on Shark Tank, securing a $250,000 investment from Lori Greiner.

“The ability to iterate rapidly – that’s what Yale Engineering really taught us,” Lee said. Some famous musicians, such as Yo-Yo Ma and The Piano Guys, have already tested and praised the instrument. A 3D-printed violin is also launched now, and additional designs are underway, so Forte3D is clear on its larger mission. According to Lee, music shouldn’t be “confined by price or fragile wood.” By making the instruments more accessible, the team is hoping to build something truly meaningful.