Summary

Metrology‑grade scanners are advanced 3D scanning systems designed for industrial inspection, reverse engineering, and quality control, offering extremely high accuracy from 0.005 mm to 0.025 mm and volumetric accuracy typically ranging from 0.02 mm + 0.015 mm/m to under 0.089 mm for large-scale volumes. Top devices—such as the Shining3D FreeScan Combo, Creaform MetraSCAN 3D‑R, and Scantech TrackScan‑Sharp—deliver impressive scan speeds up to 3 million measurements per second, establishing them as cornerstones of shop‑floor metrology and manufacturing verification tasks. [1][2][3]

Historical Background

Metrology‑grade scanners originated from developments in coordinate‑measuring machines (CMMs) and optical metrology in the late 20th century, finding their earliest roots in precision engineering labs. The first commercial handheld laser 3D scanners were introduced in the early 2000s, with manufacturers like Shining3D—founded in 2004—pioneering accessible and portable high‑accuracy scanning technologies. [1]

Technical Principles

Metrology‑grade scanners primarily use blue‑laser or structured‑blue‑light projection in combination with photogrammetry or active optical tracking systems. This approach accurately captures dense point clouds, even from highly reflective or challenging surfaces. Structured‑light scanning, using patterned light to reconstruct geometry, is especially common in high‑precision models and is well summarized in scientific and technical literature. [4]

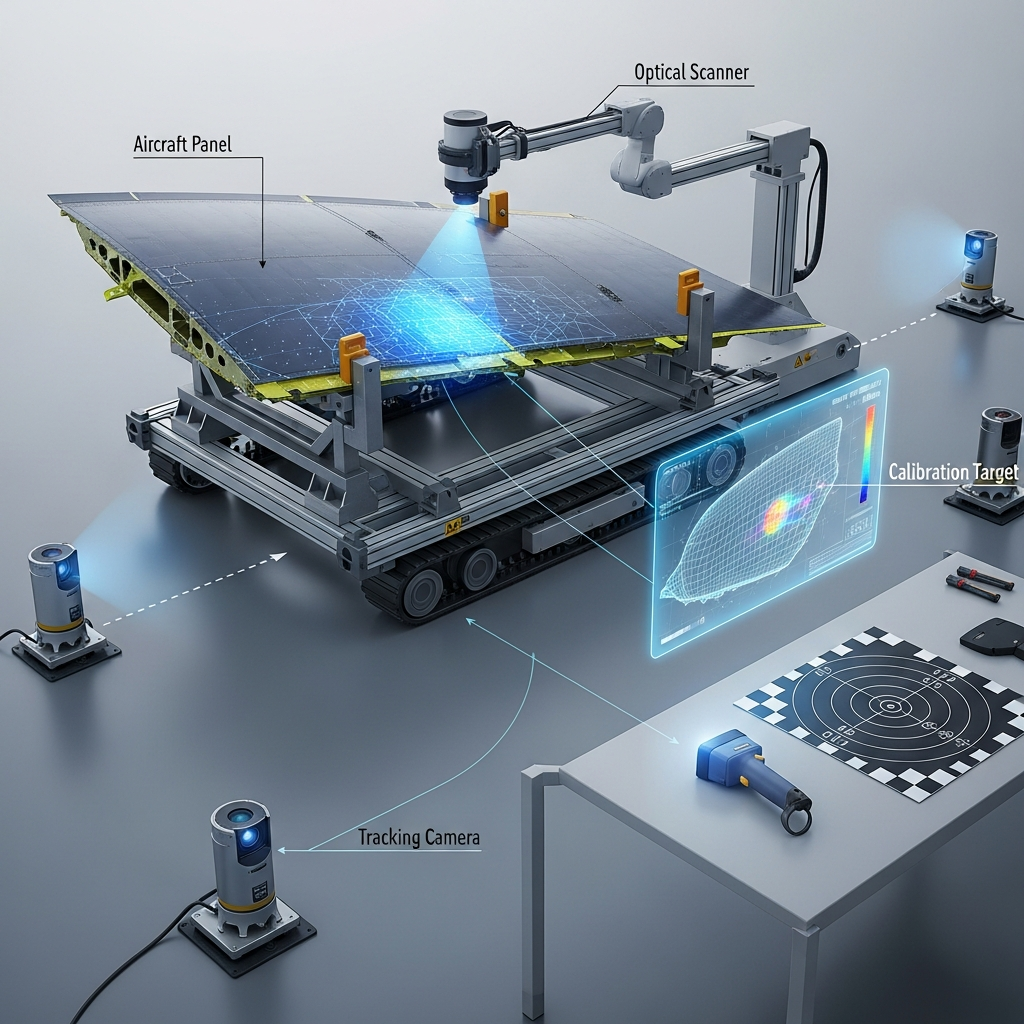

Advanced models achieve volumetric accuracy through dynamic referencing—where the scanner, part, and sometimes the environment are optically tracked simultaneously. Systems like the MetraSCAN 3D and TrackScan‑Sharp utilize such solutions, allowing high‑accuracy scanning directly on the shop floor, even if the part or environment moves. [2][3]

Types of Metrology Scanners

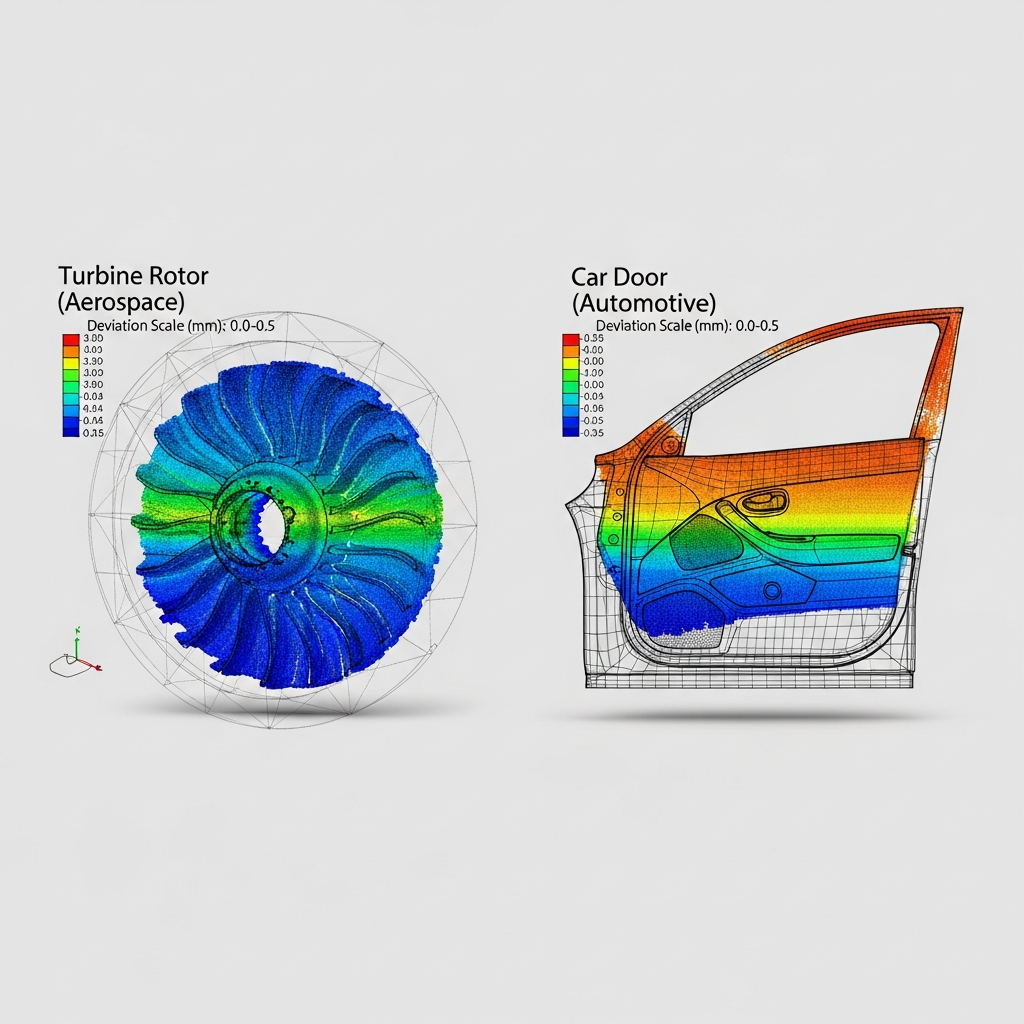

Hand‑held laser and blue‑light scanners—such as the Shining3D FreeScan Combo and OptimScan‑5M—offer outstanding accuracy in a portable form. The FreeScan Combo achieves 0.02 mm single‑scan accuracy and volumetric accuracy of 0.02 mm + 0.03 mm/m, at speeds up to 1,860,000 points per second. The OptimScan‑5M, using blue-light technology, provides a notable single‑scan accuracy of 0.005 mm, volumetric accuracy of 0.08 mm/m, and completes scans in under 1.5 seconds. These devices excel in quality control and reverse engineering tasks for small‑to‑medium parts. [1]

Portable optical CMMs like the Creaform MetraSCAN 3D and MetraSCAN BLACK+ | Elite are designed for high‑precision dimensional measurement with dynamic referencing. The MetraSCAN 3D, using 30 blue laser lines, achieves accuracy of 0.025 mm and volumetric accuracy from 0.025 mm + 0.015 mm/m, extending over volumes up to 16.6 m³ for the Elite variant. These systems can operate even in shop‑floor conditions thanks to robust tracking, and enable fast, automated measurements for demanding industrial workflows. [2]

Large‑volume optical scanning and tracking systems—such as the Scansystem TrackScan‑Sharp 49—enable high‑accuracy measurement for oversized components and assemblies. The TrackScan‑Sharp delivers up to 0.025 mm accuracy, sub‑0.1 mm volumetric accuracy at volumes as large as 49 m³, and rapid measurement at 2.6 million points per second. Such systems are crucial for aerospace, automotive, and heavy industry inspection of large, complex structures. [3]

Principal Types of Metrology‑Grade Scanners

- Handheld Laser/Blue‑Light Scanners: Shining3D FreeScan Combo, OptimScan‑5M.

- Portable Optical CMMs: Creaform MetraSCAN 3D, MetraSCAN BLACK+ | Elite.

- Large‑volume Tracking Systems: Scansystem TrackScan‑Sharp 49.

Comparison Table

| Model | Accuracy (mm) | Volumetric Accuracy | Speed (points/s) | Max Volume |

|---|---|---|---|---|

| FreeScan Combo | 0.02 | 0.02 + 0.03 mm/m | 1,860,000 | Handheld |

| OptimScan‑5M | 0.005 | 0.08 mm/m | <1.5 sec/scan | Desktop |

| MetraSCAN 3D | 0.025 | 0.025 + 0.015 mm/m | 1,800,000 | 16.6 m³ |

| MetraSCAN 3D‑R | 0.025 | 0.078 | 3,000,000 | Inline Auto |

| MetraSCAN BLACK+ Elite | 0.025 | 0.078; 0.025 + 0.015 mm/m | 1,800,000 | 16.6 m³ |

| TrackScan‑Sharp 49 | 0.025 | 0.049 @ 10.4 m³; 0.089 @ 49 m³ | 2,600,000 | 49 m³ |

| Execto‑Line (generic) | ± 0.025 | Not listed | 1,000,000 | 3 m |

Performance

Leading metrology‑grade scanners achieve scan speeds from approximately 1 million to 3 million measurements per second, with resolutions as fine as 0.005 mm and volumetric accuracy maintained across various scanning environments. Models like the MetraSCAN 3D‑R and TrackScan‑Sharp illustrate the technological advancements in fast, high‑accuracy data capture. [1][2][3]

Key factors influencing performance include surface reflectivity, ambient lighting, calibration procedures, and regular validation. Adherence to international standards—such as ISO 17025 accreditation and VDI/VDE guidelines—ensures the accuracy and repeatability of these devices, as exemplified by the strict validation protocols of premium models like MetraSCAN. [2]

Applications

Metrology‑grade scanners are employed across a broad range of sectors, including automotive design, aerospace manufacture, mold and die making, industrial quality control, heavy machinery, and the inspection of large parts or assemblies. Devices such as the FreeScan Combo, MetraSCAN 3D, and TrackScan‑Sharp exemplify this technology’s core role in ensuring precision and quality in modern industry. [1][2][3]

Research Updates

Recent research has demonstrated new frontiers such as microcomb LiDAR parallel ranging, achieving megapixel line‑scan rates—promising much faster 3D capture in the future, though not yet implemented in mainstream metrology scanners. Advances in structured‑light scanning, as seen in systems like the Hexagon ATOS SmartScan VR800, continue to expand precision and speed limits within shop‑floor environments. [4][5]

Q&A (FAQ)

What defines a metrology‑grade scanner?

A metrology‑grade scanner is a 3D scanning system specifically designed for high‑accuracy industrial measurement, typically achieving 0.005 mm to 0.025 mm accuracy and comprehensive volumetric accuracy verification—often validated by traceable standards—making them suitable for shop‑floor metrology and certified quality inspection tasks. [1][2]

How accurate are metrology scanners compared to industrial alternatives?

Metrology‑grade scanners routinely deliver greater accuracy and repeatability than generic industrial 3D scanners. While standard industrial scanners offer ± 0.025 mm accuracy and up to 0.05 mm resolution (e.g., Execto‑Line), true metrology systems achieve sub‑0.01 mm precision and rigorous volumetric guarantees, making them more reliable for critical measurement. [1][6]

What is volumetric accuracy in high accuracy 3D scanning?

Volumetric accuracy refers to a scanner’s ability to maintain measurement precision over a defined three‑dimensional space or volume. High‑end systems—such as the MetraSCAN 3D (0.025 mm + 0.015 mm/m)—ensure stable accuracy across large and complex objects, not just at single points. [2][3]

How do scan speed and resolution impact industrial scanner performance?

Scan speed, measured in points or measurements per second, affects how rapidly data is gathered and processed. Higher resolution—down to 0.005 mm—enables finer detail capture, but can increase processing demands. Top models balance speed (up to 3 million measurements/s) with optimal resolution to support fast, precise industrial workflows. [1][3]

What standards validate metrology 3D scanner accuracy?

Internationally recognized standards, such as ISO 17025 for laboratory calibration and VDI/VDE 2634 for optical 3D measuring systems, validate the accuracy and traceability of metrology‑grade scanner results. Models like the Creaform MetraSCAN are tested and certified according to these guidelines. [2]

How does dynamic referencing improve shop‑floor metrology accuracy?

Dynamic referencing ensures that the scanner, object, and tracking system remain aligned even as the environment or part moves—an advantage in real‑world shop‑floor conditions. This maintains high measurement repeatability and accuracy, as with the MetraSCAN 3D and TrackScan systems. [2][3]

Sources

- Shining3D FreeScan Combo & OptimScan‑5M Specifications — Go3DPro

- Creaform MetraSCAN 3D & BLACK+ Elite Technical Specifications — Proto3000

- Scantech TrackScan‑Sharp 49 Technical Specifications

- Structured‑Light 3D Scanner — Wikipedia

- Microcomb Enabled Mega-pixel Scale Parallel LiDAR — arXiv 2021

- Execto‑Line Handheld Laser Scanner Category