Many of the industry stalwarts I spoke to at this year’s Formnext admitted to being a bit anxious in the run up to the event. Some big names are no longer present – the likes of Markforged, Desktop Metal, and Nexa3D come to mind. Macroeconomic headwinds continue to prevail.

However, when we arrived on the showfloor, these anxieties immediately dissipated. Once again, Formnext delivered innovation in spades. Everywhere I looked there was a product launch, a new automation feature, a creative application unlike anything I’d ever seen.

As Mesago VP Sascha Wenzler put it: “a decade ago, we were still talking about what additive manufacturing might become in the future. Today AM is no longer a promise. It is production, it is strategy, and it is impact.” No doubt, Formnext celebrated its tenth anniversary with a bang – and the appetite for cutting-edge 3D technology remained as strong as ever in Frankfurt.

This is especially true on the consumer side, which is bucking wider downward trends. SLM Solutions, acquired by Nikon a few years ago, also had a big presence, while heavy-hitters EOS & Wayland Additive used the show to build hype around new 3D printer launches.

Let’s take a look at the news that impressed 3D Mag most, starting with fused deposition modeling (FDM) and stereolithography (SLA) 3D printers for our maker readers!

Prusa brings craftsmanship, Bambu Lab debuts new H2C

Visiting Prusa’s booth at this year’s Formnext, it was impossible to miss an absolute beauty of a 3D printer operating in the corner. Made from slabs of Czech wood, the Prusa Signature Oak is basically a limited edition ultra-stylish Core One. Having seen the machine first-hand, I have to say the craftsmanship is amazing – it would be a great statement piece in your living room.

And every one of the 250 units is hand signed by Josef Prusa himself. Given the number of Prusa fanboys out there (the booth was heaving), I don’t think they’ll have trouble shifting stock.

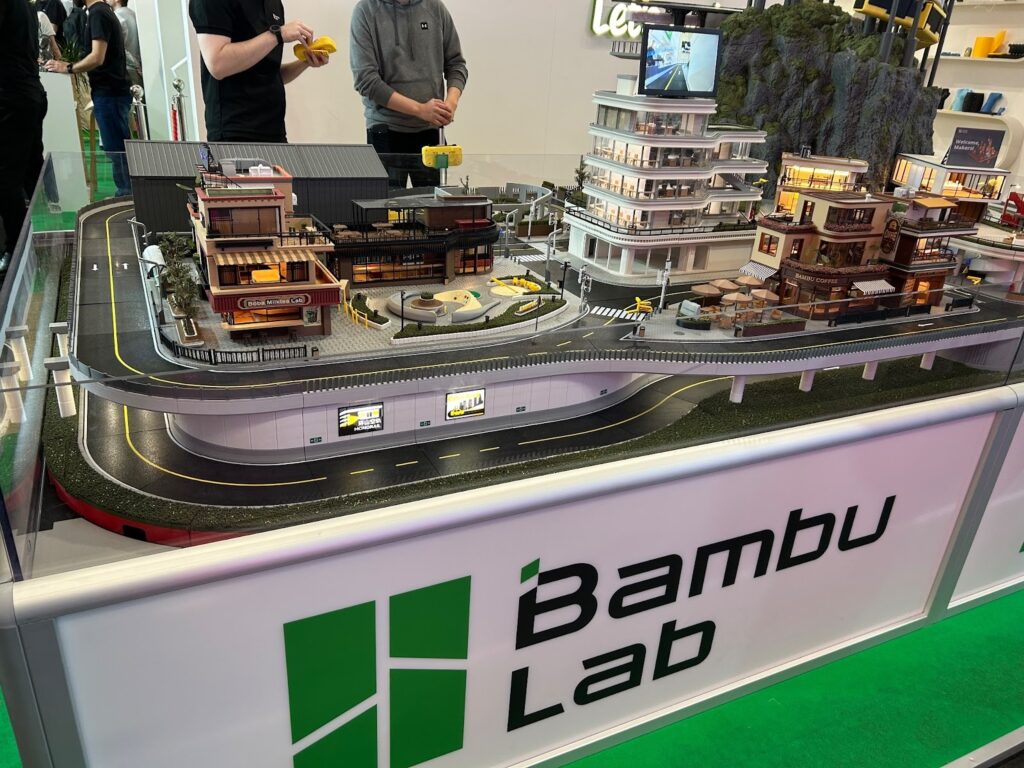

Bambu Lab, which is fast building its own fanbase, exhibited at a similar toy-themed booth to last year’s. It makes sense considering they launched the “CyberBrick” electronic toy 3D printing Kickstarter earlier this year. Product-wise, its beastly new H2C 3D printer grabbed many industry headlines – the 7-nozzle, multi-material system is sure to be a hit among designers.

HeyGears also showcased a bunch of new SLA products, including two machines: the Reflex 2 & Reflex 2 Pro. Powered by the company’s OptiZone Light Engine technology, the system incorporates 1,032 individually controlled light zones, ensuring high-precision and consistent surface quality. The “Pro” version is not only larger, it also has an FOC motor module.

Both these features make it better suited to high-speed, batch production – whether it be for product design, prototyping, or making end-use parts. This system works with HeyGears’ new PAH270 material as well, which is designed for high-durability. “Expanding from prototyping into production” is a classic line in the 3D printing industry. But these new tools will certainly help!

Metal 3D printing has lift-off at Formnext

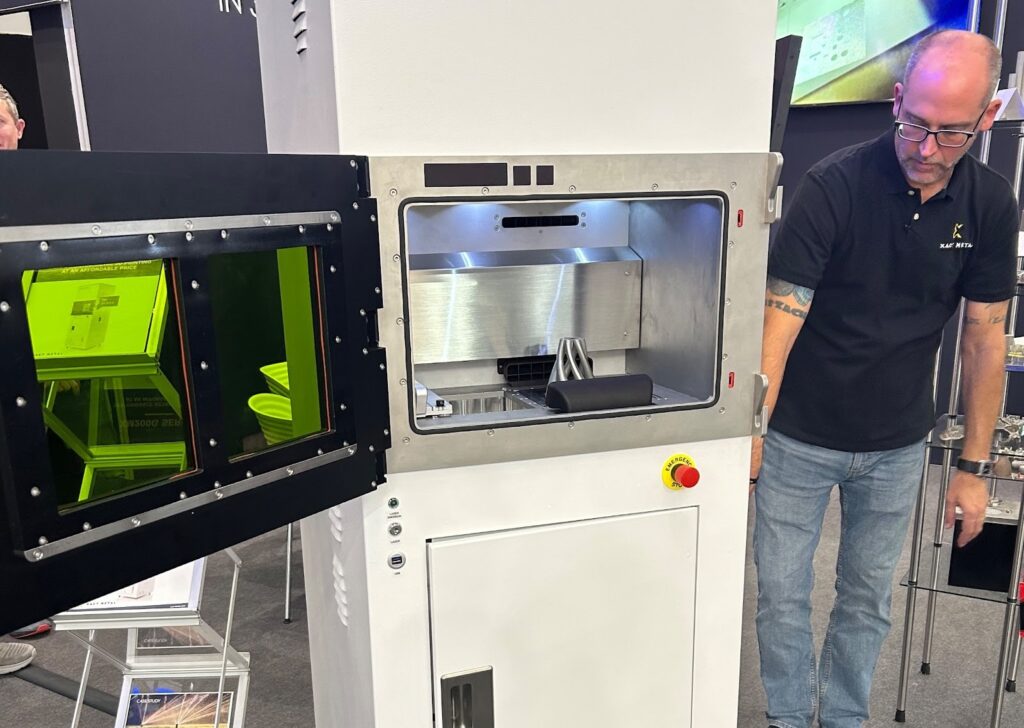

Xact Metal has made a bit of a name for itself in the budget metal 3D printing space. At this year’s Formnext, it built on this reputation with the XM200G μHD – a machine capable of printing 5-15um-sized powder, allowing it to create smaller parts and smoother surfaces. I didn’t see pricing info, but the company usually markets its products at around $100,000.

This may sound pricey to consumer/maker users, but it’s priced well against industry competitors. Its ability to print refined powder is ultimately going to expand the possibilities for those making their steps in the world of metal 3D printing – think researchers and SMEs.

At the other end of the metal 3D printing spectrum, EOS showcased an absolutely massive new industrial system called the M4 ONYX. Featuring a spacious 450 x 450 x 360 mm build area, the machine is designed to pick up where the M400 left off: the high-productivity laser powder bed fusion (LPBF) 3D printing of parts for defense, aerospace, automotive, and more.

Said to deliver 50% higher throughput and a 30% drop in cost-per-part, EOS has gone to great lengths to highlight how users can quickly get a tidy return on their investment.

At their booth, Wayland Additive were keen to highlight the practical applications of its Calibur3 technology. The company has forged close ties with the Royal Air Force – and a 3D printed weapon system-connecting assembly is now flown onboard Typhoon fighter jets. To showcase the possibilities in this area, a 3D printed torque converter and heat exchanger were on display.

As you can see in the image below, there was also an impressive full-volume lattice designed to deliver aerospace-grade strength at a lower weight with reduced material costs.

Game-changing 3D software updates

Artec 3D is known for professional 3D scanning – and it’s still operating in this space. But at Formnext, it launched a product that also unlocks new opportunities: AI-driven photogrammetry. Artec introduced the feature in the last version of its software, Artec Studio 19. However, it’s now marketing photo & video-based modeling as a separate product: Artec Studio Lite.

Open to anyone with a smartphone, the software essentially makes the company’s high-end capture tools more readily available to an entry-level audience. Its team even had a live demo in the shape of an app that allowed visitors to capture objects and process data on the cloud. It was only a demo, but it showed the kind of results you can achieve with the desktop version.

Polygonica also showcased version 3.5 of its software, which brings enhanced quad remeshing and allows for non-planar quad surface generation. These features build on the program’s already strong remeshing capabilities, allowing for more uniform, less noisy results, as well as improving support for traditionally difficult to capture curved, complex geometries.

At the nearby Renishaw booth, the company showcased its latest performance-enhancing software: Libertas. Said to allow for unprecedented laser parameter tuning, the technology helps users reduce their reliance on supporting structures and improve surface finish. This, in turn, minimizes post-processing time in a way that maximizes productivity in industrial settings.

Other points of interest at Formnext ‘25

As always at Formnext, there were plenty of surprises outside of mainstream product news. On the showfloor, there were guided tours for the first time. The sight of tour guides in busy areas made me double take a few times. But it seemed a helpful way to help newcomers navigate. There was also a stand with branded merch, which brought on strong festival vibes.

It was interesting to see a jewelry manufacturer named CooksonGold at the exhibition. More of a 3D technology user than a developer, the company offers jewelry customization services using Artec Micro II 3D scanning. On a more personal note, it was also great to see pro hacker/modder Ken Pillonel. I reported a few years ago that he’d developed a 3D printed mod for iPhones and now he makes them commercially with Formlabs. Kudos to him.

Elsewhere, presentations on the Industry stage provided some fascinating insights. For example, Tobias Hehenwarter, CEO of ID Design, told attendees about how design for AM is reliant on not being so afraid of ‘holes’ in products – and deviating from natural structures. It was a little provocative (given how much AM borrows from the natural world). But it prompted a lively debate about the best way to integrate 3D printing. Exactly what Formnext is all about!

Discover further insights via Formnext’s stage presentations here. Stay tuned for our Awards article (coming soon), or compare our write-up to last year’s at Formnext 2024.