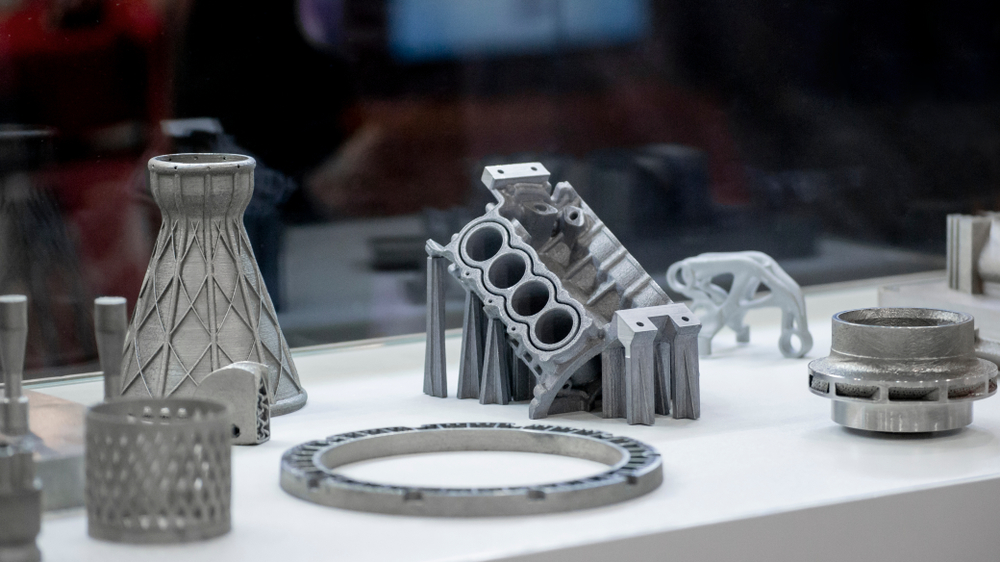

Automotive supplier Brose sets a new industry standard by taking its additive manufacturing to the next level with its new metal 3D printer, currently one of a kind in Germany. Built in collaboration with Farsoon Technologies, this system features an extended build space, multiple lasers, and increased power, enabling bigger components and more efficient series production.

The strategic goal for Brose is to make production significantly more competitive and sustainable. The new printer’s extended build chamber is critical, as it allows for large and complex components to be produced in a single print job, eliminating the need for subsequent joining steps. This step, combined with increased laser power, also means that smaller components can be produced in higher quantities.

The innovation indicates an important transition. “This technology marks a decisive shift toward additive series production in the mobility sector,” Eric Fritzsche, head of Additive Manufacturing, said in a press release. “We are consistently driving forward the additive series production of automotive components. Especially for complex or highly variant parts, 3D printing gives us an economical and flexible alternative to conventional processes.”

A major highlight is the printer’s commitment to the circular economy. The metal powder is its unique distinctive feature – and selling point – as it consists entirely of recycled punching scrap from Brose’s own press shops. The recycled material retains the same chemical composition and mechanical properties as conventional sheet metal components, returning production waste directly back into the manufacturing cycle.

The collaboration with Farsoon was crucial to this industrial leap. “Together with Brose, we have transformed innovation into real production efficiency – an excellent example of what strong partnership and open technology can achieve,” said Oliver Huizhi Li, managing director at Farsoon Europe.

Brose is also using additive processes for new product development, applying original series materials for rapid prototyping. This tool-free process brings maximum flexibility for design changes, showing how economic and flexible the 3D printing future can be from development to mass production.

From November 18 to 21, Brose will reveal a sample print from the new system at Farsoon’s stand (Hall 11, Stand E11) at Formnext.