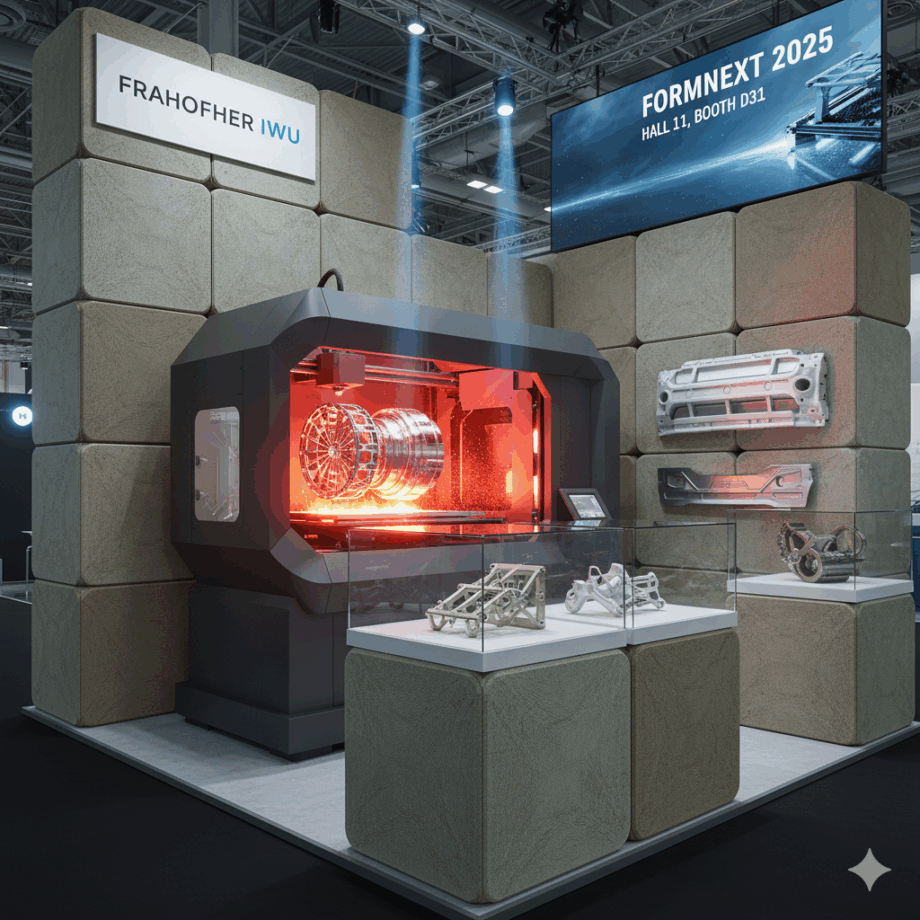

3D printing reaches 1200 °C at Formnext this year with Fraunhofer IWU unveiling high-temperature aerospace materials. The company matches its display with the innovation it presents by 3D printing its booth using sustainable materials. Made from biodegradable plastic and budget-friendly, recyclable polypropylene (PP) granulate, the modular furniture will be reassembled and repurposed after the event. Fraunhofer IWU aims to demonstrate the real-world utility of 3D printing that is both sustainable and large-scale.

At the core of the exhibition are advanced materials and high-performance applications in the aerospace industry. One of the highlights is a new high-temp Laser Powder Bed Fusion system that preheats the powder bed up to an unprecedented 1200 °C. This innovative system streamlines the processing of refractory metals like tungsten and metallic materials such as titanium aluminide. According to Fraunhofer, this brings “new possibilities for higher resolution, especially thin-walled structures, and precise control over the resulting microstructure”. This is especially useful for creating lightweight yet highly wear- and temperature-resistant components, essential for high-performance engine parts and heat exchangers.

There are even more material breakthroughs, such as Aluminum Matrix Composites (AMC), a lightweight solution for the automotive and aerospace sectors. Research team led by Dr. Florian Bittner has integrated silicon carbide (SiC) particles into the aluminum matrix to enhance the tribological properties, resulting in excellent wear resistance. The institute is also working on the process strategies for Constellium Aheadd® HT2, a heat-resistant aluminum alloy for components that must withstand service temperatures up to 300°C.

Beyond materials, Fraunhofer IWU demonstrates practical industrial applications like a 3D-printed rear shelf developed with MOSOLF Special Vehicles GmbH for the Mercedes Vito, which saved 26.5 kg compared to previous solutions. Another showcase is the WEAM process for direct integration of electrical functions into components.

Fraunhofer exhibits at Formnext, Frankfurt am Main, November 18–21, in Hall 11, Booth D31.