Summary

Masked Stereolithography (MSLA) is a resin 3D printing technology that employs an LCD screen to mask and cure entire layers of photopolymer simultaneously, unlike traditional SLA’s point-by-point laser tracing. MSLA enables faster print times and higher throughput, with resolutions defined by LCD pixel size. This approach offers significant advantages in batch production speed, XY print accuracy, and the ability to achieve fine surface detail. [1] [2]

Historical Background

The origins of stereolithography (SLA) date to 1984, when Chuck Hull invented the process—later commercialized by 3D Systems in the United States—enabling the first photopolymer-based rapid prototyping. Advancements in LCD panel technology in the early 21st century made masked approaches feasible, leading to MSLA’s emergence. [1]

The transition toward desktop inverted SLA began with the introduction of the Formlabs Form 1 in 2011, developed in Massachusetts, USA. This affordable, compact device catalyzed a wave of interest in masked variants as hobbyists and professionals experimented with consumer-grade LCD displays as dynamic masks. LCD-masked resin printing, now known as MSLA, emerges directly from this lineage, leveraging advances in display and UV LED illumination to democratize precision resin 3D printing. [1]

Principles of Operation

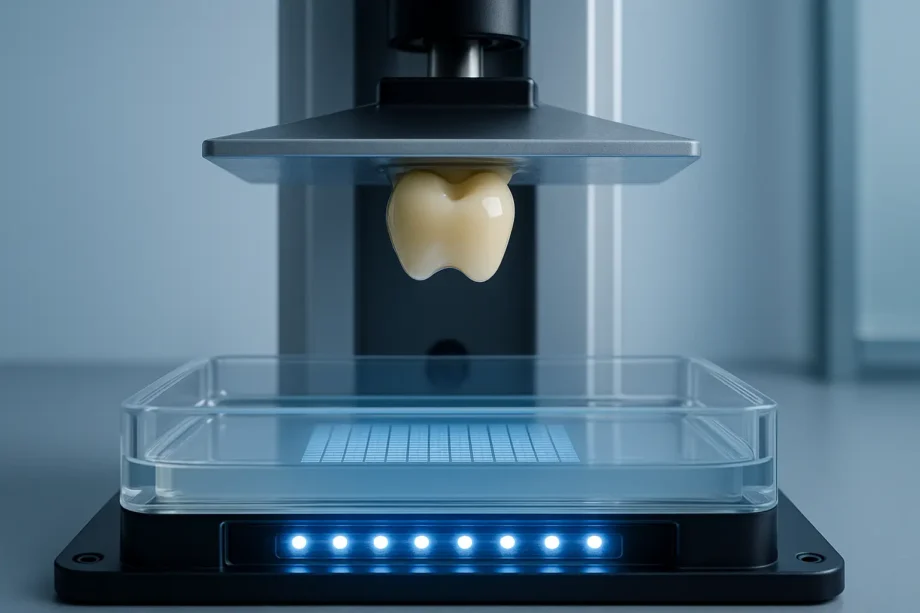

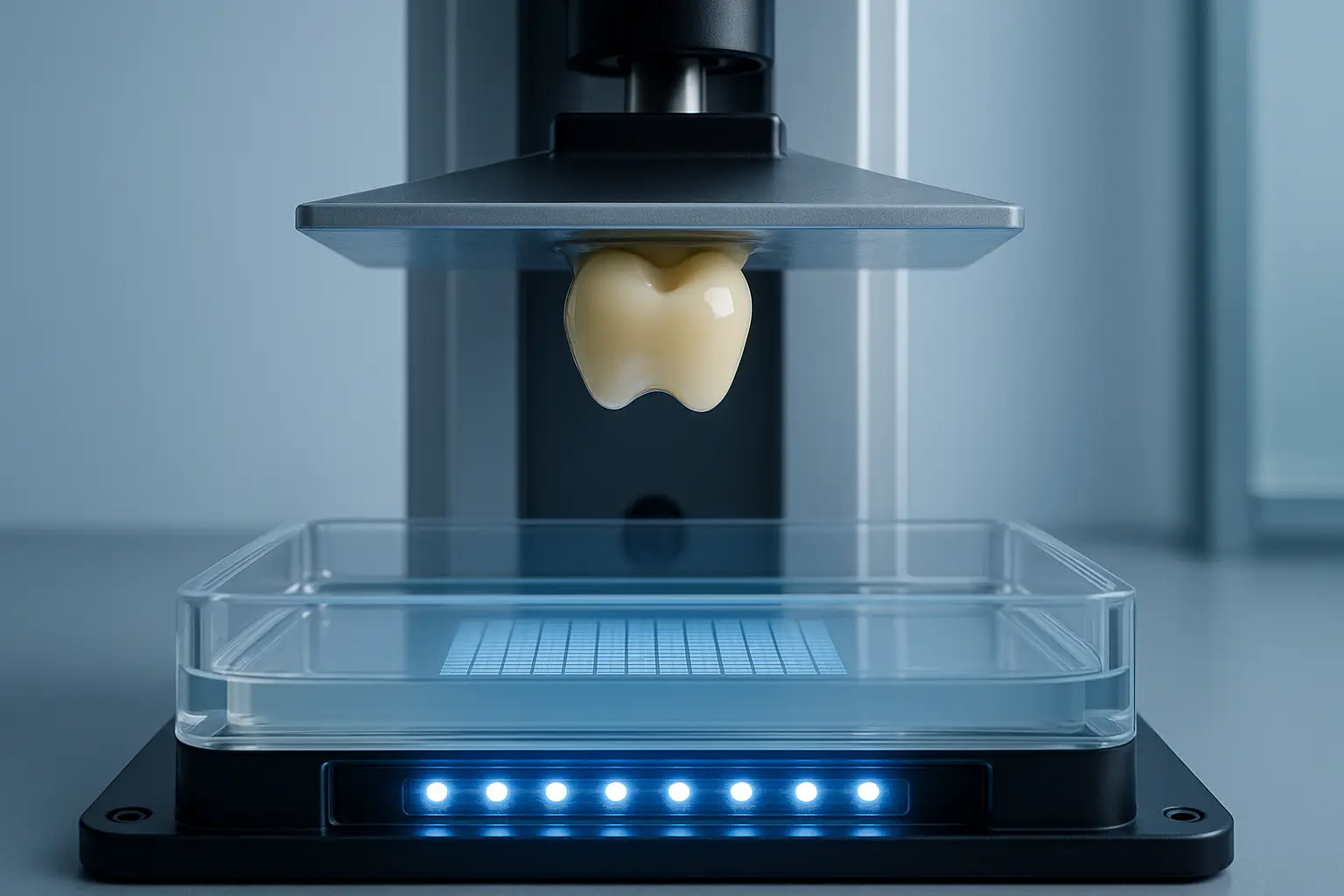

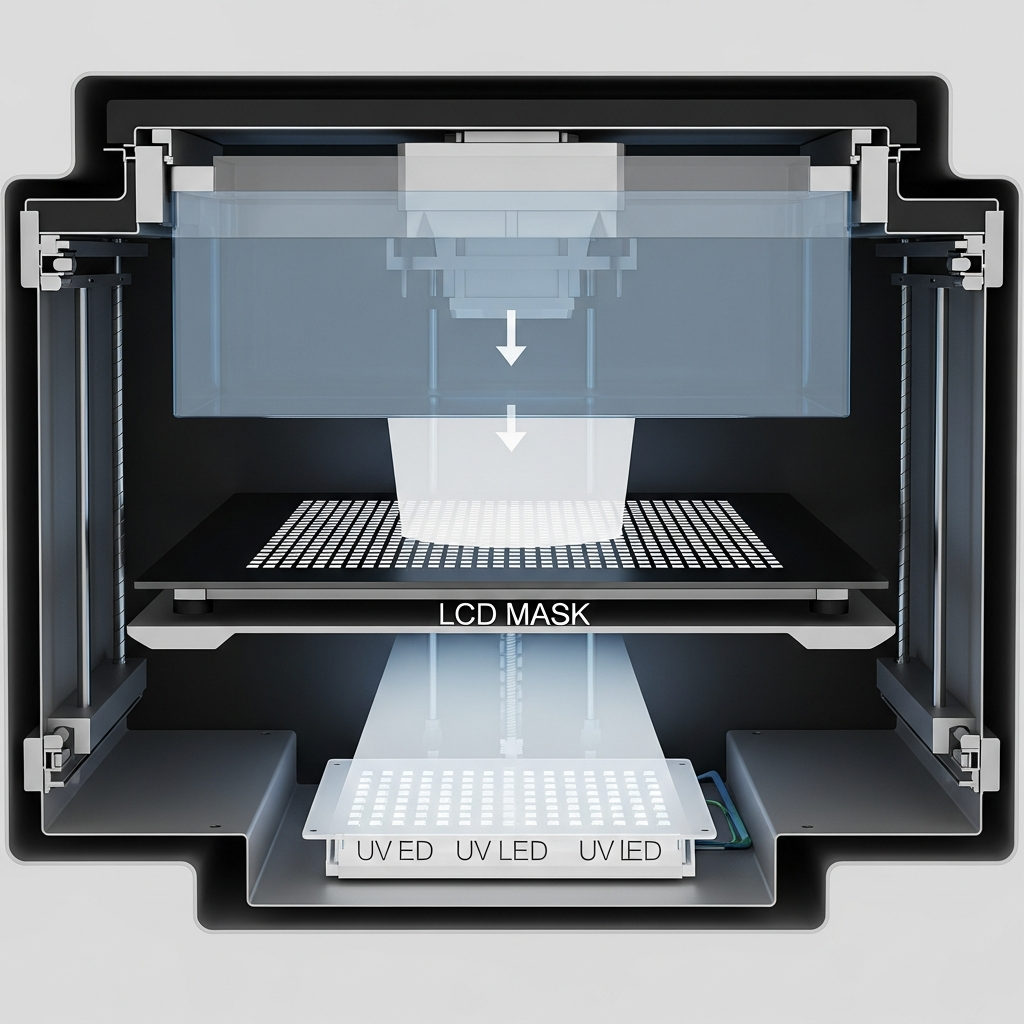

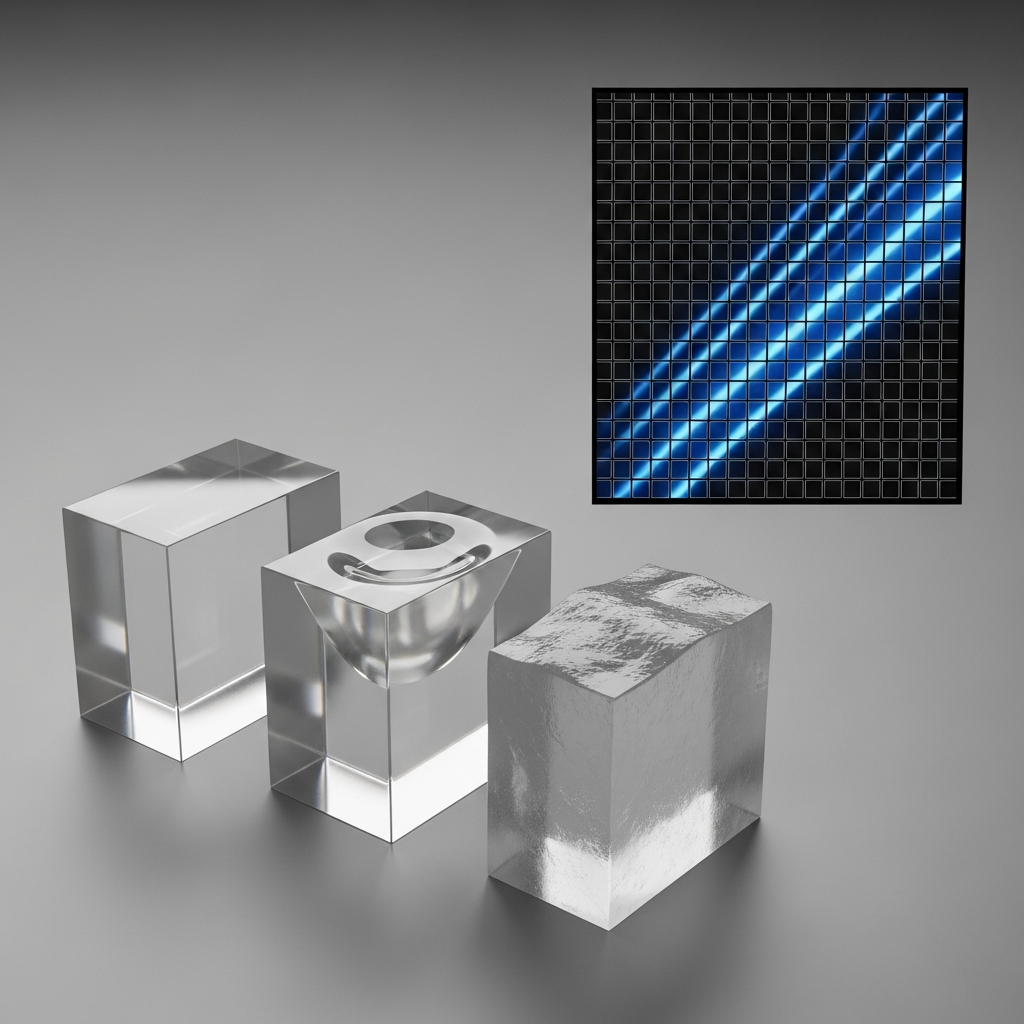

Traditional SLA 3D printers use a focused ultraviolet (UV) laser to trace the cross-section of each layer onto a photopolymer resin surface, with the laser spot size—typically ~85 µm in popular models like the Formlabs Form 3+—limiting XY accuracy. In contrast, MSLA uniformly projects UV light through a liquid crystal display (LCD), which acts as a dynamic mask, curing every exposed pixel (typically from 25–75 µm) in parallel per layer. The result is much faster layer times, around 1–10 seconds, as the entire cross-section is fixed in a single exposure, irrespective of complexity. [2] [3]

Performance

Print speed is a major advantage of MSLA—average rates are around 40 mm/hr, but top-tier systems like the Creality HALOT-MAGE reach up to 170 mm/hr, with the Saturn 4 Ultra specified at a maximum of 150 mm/hr. [4] [5] [6]

MSLA print tolerances are highly competitive. Formlabs benchmark data cites dimensional accuracy of ±0.15 % (minimum ±0.02 mm) for features up to 30 mm, ±0.2 % (±0.06 mm) for 31–80 mm, and ±0.3 % (±0.15 mm) from 81–150 mm. Surface fidelity is equally impressive: 99.7 % of surfaces can be held within 100 µm, 95 % within 50 µm, and about 69 % within 25 µm—figures crucial for fields like restorative dentistry and jewelry. Resin volumetric shrinkage, typically 7.66–11.2 % by formulation, can be reduced to as low as 7.28 % with experimental resins, further enhancing dimensional accuracy. [2]

A representative academic study specifies key MSLA printing parameters: 0.050 mm layer thickness, 8 s exposure time with 1 s off time and a bottom exposure of 60 s, pixel size at 47.25 µm, and a printing speed of 20 mm/hr. These parameters illustrate the foundational trade‑off between resolution and throughput—smaller pixel size and thinner layers yield sharper details but slower builds and increase light scattering artifacts. Notably, MSLA LCD screens degrade with UV exposure; typical replacement intervals fall between 1,000–2,000 hours, and consistent calibration is needed for optimal print quality and light uniformity. [3] (Editor: include a comparison table summarizing MSLA print speed and accuracy characteristics, e.g., Creality HALOT-MAGE, Formlabs Form 3+, and Saturn 4 Ultra).

Applications

MSLA has established itself across varied professional domains: dental laboratories rely on rapid, repeatable production of highly accurate restorative models; jewelry makers employ MSLA for finely detailed casting masters; engineers use it for functional prototypes and batch production of complex geometries; and hobbyists benefit from speed and detail for custom miniatures. The synergy of high surface fidelity and speed makes MSLA a leading technology where both throughput and finish are paramount. [2] [7]

A growing area of research is deploying MSLA for microfluidic device fabrication, enabled by the tight control over layer thickness and expanding resin options—including flexible and biocompatible SLA elastomers—supporting innovation in lab-on-chip platforms. [8]

Research Updates

Ongoing MSLA research focuses on advanced resins with lower shrinkage (down to 7.28 %), thereby reducing volumetric warping post-cure. New light engine innovations like LSPc (Linear Sweeping Photopolymerization) minimize peel forces, safeguarding fine details and enabling faster production. Meanwhile, the industry is rapidly scaling LCD panel technology, with hardware now shipping standard 4K–16K masks, which boost both build volume and XY resolution. These improvements are driving wider adoption in dental, R&D, and manufacturing fields—pushing MSLA further into roles traditionally held by industrial SLA. [2] [9]

FAQ

1. What is Masked SLA and how does it differ from traditional resin SLA?

Masked Stereolithography (MSLA) uses an LCD screen to selectively block or transmit UV light across a resin vat, curing an entire layer’s shape at once. Traditional SLA traces each cross-section point-by-point with a laser. This means MSLA is generally faster for complex layers and batch production. [2]

2. How does LCD resin printing improve print speed compared to SLA?

LCD resin printing (MSLA) exposes an entire layer simultaneously; layer times are typically 1–10 seconds regardless of model complexity, whereas laser-based SLA can be significantly slower for dense or complex geometries. MSLA printers like Creality HALOT-MAGE achieve speeds up to 170 mm/hr. [3] [4]

3. What accuracy and tolerance can I expect from MSLA vs SLA?

MSLA systems such as those from Formlabs exhibit tolerances of ±0.15 % (min ±0.02 mm) on features up to 30 mm, with surface fidelity rates of 99.7 % within 100 µm—comparable to SLA. Actual results depend on printer calibration, resin behavior, and LCD resolution. [2]

4. (Expert-level) How do resin shrinkage values (e.g., 7.28 % vs 11.2 %) affect volumetric accuracy in MSLA prints?

Lower resin shrinkage contributes to improved volumetric accuracy and dimensional integrity in printed parts, minimizing post-cure warping and dimensional deviation—especially critical for precise engineering or dental applications. Selecting engineered resins with shrinkage as low as 7.28 % increases print reliability and repeatability. [2]

5. (Expert-level) How do pixel size and light uniformity factors influence XY resolution in MSLA?

XY resolution in MSLA is inherently limited by the LCD’s pixel size (typical range: 25–75 µm), and uneven UV illumination can produce visible banding or uneven polymerization. High‑resolution LCDs (e.g., 19×24 µm on Saturn 4 Ultra) and proper light diffusers are crucial to maintain fine detail and dimensional fidelity. [3] [6]

6. Is MSLA vs SLA better for batch production or fine-detail single prints?

MSLA excels in batch production where speed is essential, as build time per layer remains constant regardless of object count. For ultra-fine details with complex geometries, SLA’s steerable laser maintains advantages, but modern high-resolution MSLA rivals or surpasses SLA for most fine‑detail applications. [2] [6]

Sources

- 3D Mag: Resin Printing (SLA, UV Resin) Technology Guide

- Liqcreate: The Difference Between MSLA and SLA Resin

- MDPI: Influence of Masked Stereolithography Parameters

- Creality Forum: SLA vs MSLA 3D Printing — What’s the Difference?

- The Sun: Elegoo Saturn 4 Ultra Review

- Formlabs: Form 3+ Specification Sheet

- 3D Printing Industry: Dental 3D Printing Overview

- arXiv: Applications of SLA and MSLA in Microfluidics

- 3D Printing Industry: High-Resolution MSLA Developments