Summary

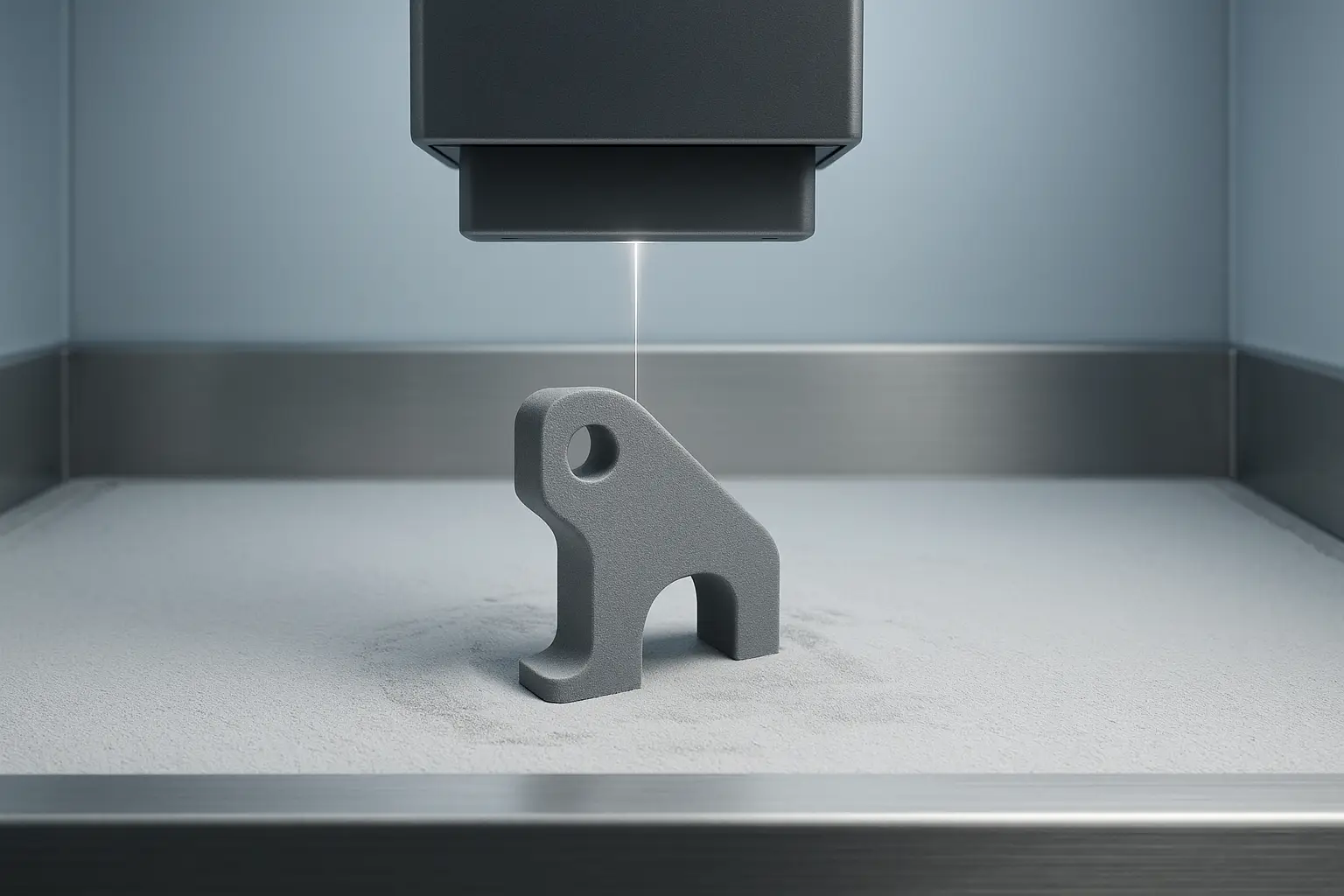

Selective Laser Sintering (SLS) is an additive manufacturing process in which a laser selectively fuses nylon powder to build durable 3D parts layer by layer. SLS was invented in the mid-1980s at the University of Texas at Austin by Dr. Carl Deckard and Dr. Joe Beaman. Typical layer resolutions range from 10 to 200 µm, with powder particles sized 15–100 µm. These performance metrics, along with robust tolerances, have driven SLS’s widespread adoption. [1] [3] [4]

Historical Background

Selective Laser Sintering originated at the University of Texas at Austin in the mid-1980s, developed by Dr. Carl Deckard and Dr. Joe Beaman. Their early experiments culminated in a patent application filed on October 17, 1986; this patent was issued in January 1997 and remained in force until January 28, 2014. These developments laid the foundational intellectual property for SLS, securing its role in the evolution of digital manufacturing. [1] [2]

Commercialization efforts quickly followed. Desk Top Manufacturing (DTM), founded to bring SLS to market, played a pivotal role in scaling the technology for industrial use. In 2001, DTM was acquired by 3D Systems, a move that accelerated SLS innovation and market penetration by joining resources with an established 3D printing pioneer. [8]

Technical Principles

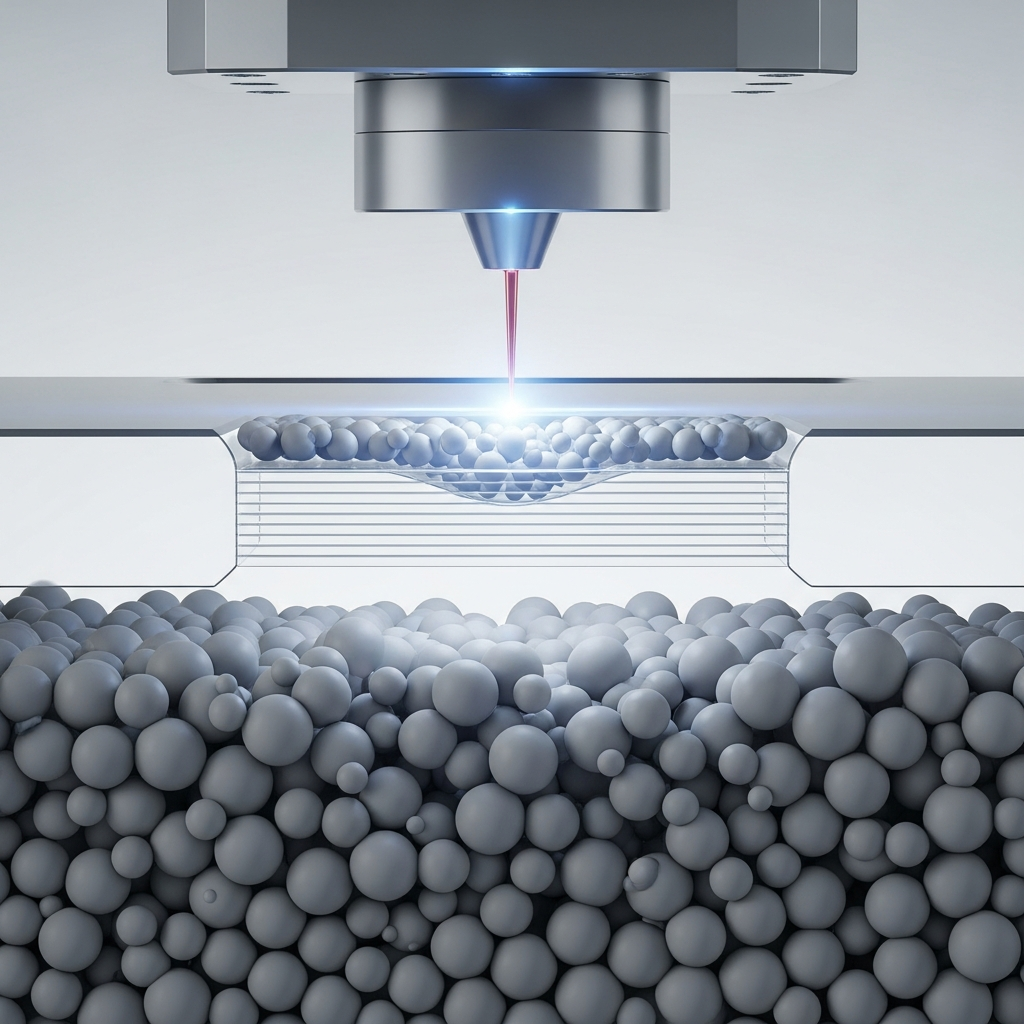

Selective Laser Sintering is a powder bed fusion technology that builds 3D objects by fusing tiny particles of thermoplastic powder—often nylon—using a high-power laser. Unlike melting-based processes, SLS performs sintering, where heat is used to fuse the particles below their melting point. Key technical principles include:

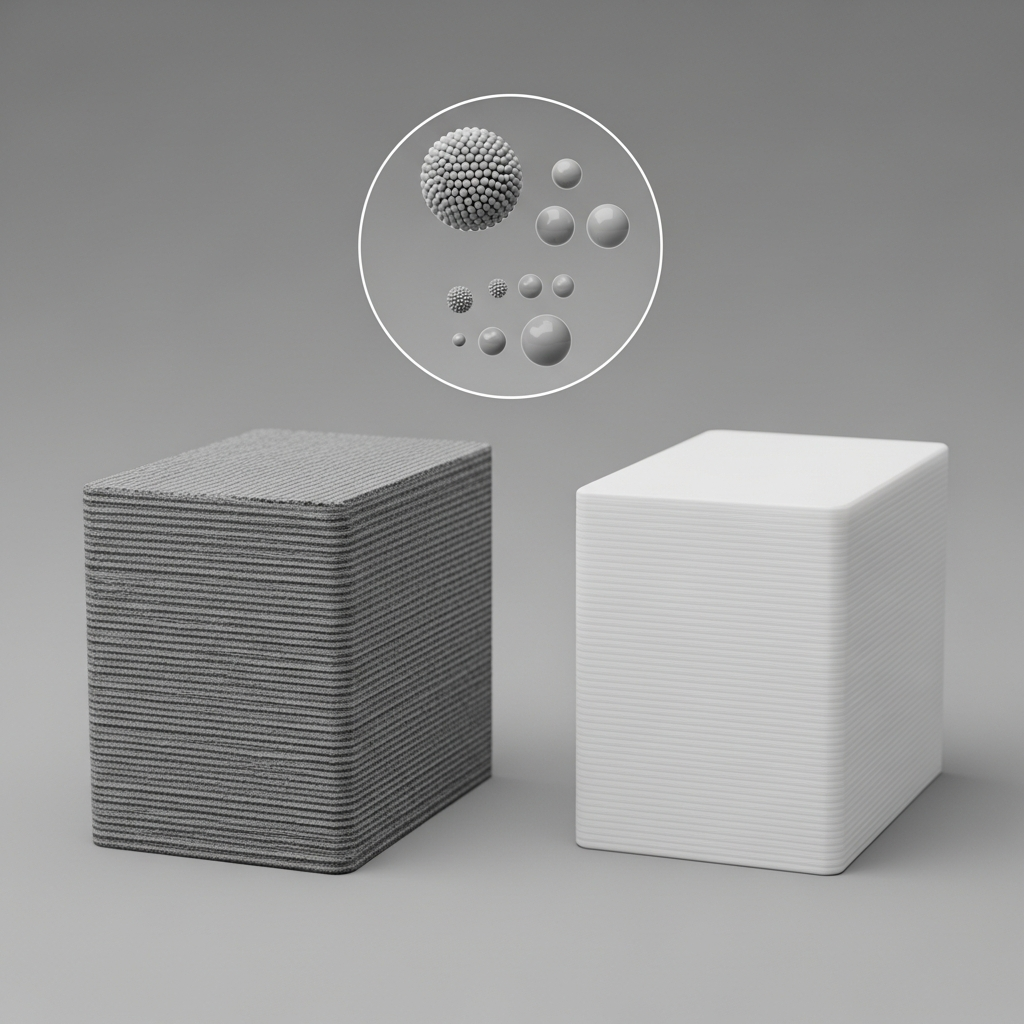

- Use of powder particles typically ranging from 15 to 100 µm.

- Layer thickness control between 10–200 µm, with commercial machines supporting specific increments (e.g., 60, 100, 120 µm).

- The laser selectively fuses material to form each successive cross-section of the part.

- No need for additional support structures: unsintered powder acts as a natural support during printing.

- High energy usage permits dense, mechanically robust components suitable for demanding applications. [3] [4]

Types and Equipment

SLS printing encompasses both general-purpose and advanced industrial machines. Industrial equipment, such as the EOS P396 and P110 Velocis, offers large build volumes (up to 340 × 340 × 600 mm), while the 3D Systems SLS-300 provides a 300 × 300 × 300 mm workspace with 0.1 mm precision and printing speeds of 12 mm/h. These variations enable a spectrum of throughput and accuracy for different manufacturing needs. [5] [7]

Comparison Table: SLS Equipment

| Model | Build Volume (mm) | Layer Resolution (µm) | Precision (mm) | Speed (mm/h) |

|---|---|---|---|---|

| EOS P396/P110 Velocis | 340 × 340 × 600 | 60, 100, 120 | n/a | n/a |

| 3D Systems SLS-300 | 300 × 300 × 300 | 100 | 0.1 | 12 |

Performance Metrics

Resolution in SLS printing depends on layer thickness, which typically ranges from 10 to 200 µm depending on the application. Finer layers (e.g., 60 µm on EOS systems) enhance surface finish and detail, but result in longer build times due to the increased number of layers required. Coarser layers improve throughput at the expense of surface quality and fine detail reproduction. The choice of powder particle size, generally 15–100 µm, also impacts the quality of the finished part. [3] [4]

Dimensional accuracy is a major advantage of SLS, especially for engineering-grade parts. For commonly used nylon PA12, tolerances are ±0.25 %, with a typical lower limit of ±0.25 mm. This tight control minimizes dimensional variation and allows for precise fit and function in assemblies. In comparison, flexible materials such as TPU have specific tolerance ranges based on part size categories, ensuring flexible components remain within required specifications. [6]

In terms of speed, SLS printers like the 3D Systems SLS-300 can process builds at rates up to 12 mm per hour, within a build volume of 300 × 300 × 300 mm. Throughput depends not only on build height, but also layer thickness and part density within the powder bed. Industrial SLS printers are capable of running continuous or high-volume batch operations, making them well suited for both prototyping and production-scale manufacturing. [7]

Applications

SLS printing is widely used across diverse industries due to its design flexibility and robust part properties. Major fields include:

- Aerospace

- Automotive

- Medical devices

- Consumer products [1]

Research Updates

Recent developments in SLS include the introduction of new materials such as composites and polymer blends, extending its range of engineering capabilities. The expiration of core SLS patents in 2014 has spurred market growth, allowing for the emergence of desktop and cost-reduced SLS printers. This democratization of SLS is being further accelerated by open material platforms and ongoing advances in process control, broadening both accessibility and the range of viable applications. [2] [4]

Q&A (FAQ)

What is SLS printing and how does Selective Laser Sintering work?

SLS printing uses a laser to selectively fuse nylon powder into solid objects layer by layer. Developed by Dr. Deckard and Dr. Beaman in the 1980s, SLS employs powder particles typically 15–100 µm in size. The laser sinters — rather than melts — the powder, enabling robust parts with complex shapes and no support structures. [1] [3]

What nylon powder 3D materials are used in SLS?

The most common SLS material is nylon PA12, known for its strength and stability. Other options include nylon PA11 and flexible TPU, each offering different mechanical properties and tolerances for varied industrial uses. [6]

What are typical layer resolutions in SLS printing?

SLS layer thicknesses generally range between 10–200 µm. EOS SLS machines specifically offer settings of 60, 100, and 120 µm, balancing build time with surface finish and detail fidelity. [4]

How accurate and precise are SLS-printed parts?

For nylon PA12, SLS achieves tolerances of ±0.25 % or ±0.25 mm minimum. High-precision machines like the SLS-300 can reach 0.1 mm accuracy, making SLS suitable for both high-tolerance prototyping and end-use production. [6] [7]

How does SLS compare to other powder-bed fusion technologies in terms of materials and resolution?

While SLS typically uses thermoplastics such as nylon, related technologies like Selective Laser Melting (SLM) focus on metals and require full melting. SLS generally offers fine layer resolution and does not need support structures, whereas SLM is used for high-performance metal parts. See comparison table under Types and Equipment.

What is the impact of patent expiration on the adoption of SLS printers?

The expiration of foundational SLS patents in 2014 has led to increased competition and innovation in the SLS market. This has enabled the rise of desktop SLS printers and broadened access to SLS technology for smaller businesses and research labs. [2] [5]

Sources

- Wikipedia: Selective laser sintering

- Wikipedia: Selective laser sintering (History, Patent)

- Wikipedia IT: Selective Laser Sintering (Particle size)

- Wikipedia IT: Selective Laser Sintering (Layer thickness)

- Forge Labs: Selective Laser Sintering Guidelines (Build volume)

- Forge Labs: Selective Laser Sintering Guidelines (Tolerances, Materials)

- 3D Systems: SLS-300 3D Printer Specifications

- Wikipedia: Selective laser sintering (DTM Acquisition)