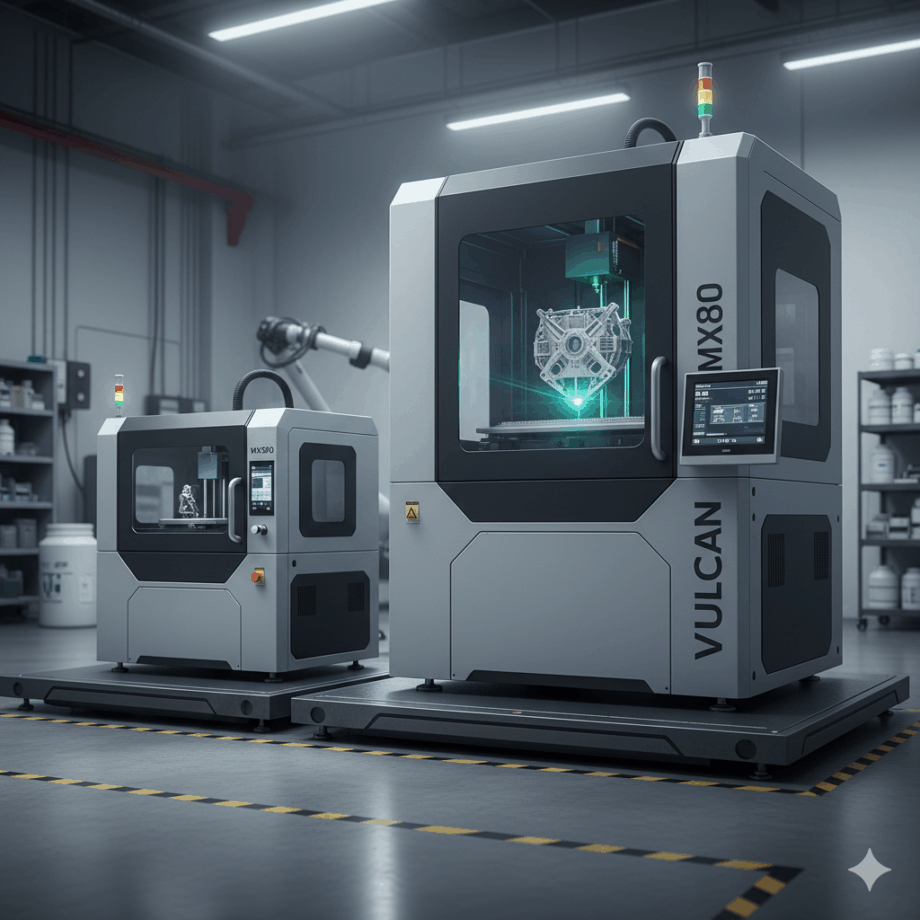

Metal 3D printing has just become much more accessible. Vulcan has launched its new MX Series of laser powder bed fusion (LPBF) metal 3D printers at a price that could democratize the industrial additive manufacturing market – starting at $39,000.

According to a press release, the company wanted to close the gap between cost and capability. “With the MX Series, any business, from a small research lab to a full-scale production facility, can integrate metal additive manufacturing into their workflow,” said the company’s spokesperson.

The MX lineup consists of eight models ranging from the compact MX100, designed for precision components in tight spaces, to the MX800, one of the industry’s largest LPBF systems, featuring an 800 x 600 x 900 mm build volume. Each printer fuses fine metal powders layer by layer with high-power lasers, resulting in surface finishes so smooth that many parts need little to no post-processing.

Layer thicknesses vary from 20 microns for fine detail to 120 microns for faster builds, providing users with a balance of precision and speed. The MX Series supports a diverse palette of materials, from titanium and cobalt-chromium alloys to copper and aerospace-grade aluminum. With such capabilities the series can serve a wide range of applications in aerospace, medical, automotive, and energy production.

Vulcan’s engineering focuses on both efficiency and safety. With their multi-laser systems, closed-loop powder handling, and automated calibration, the machines are faster, cleaner, and easier to operate. According to the company, they don’t see additive manufacturing as experimental. Instead, they consider it an essential tool, helping manufacturers to make production smarter, lighter, and faster.