Summary

A raft in 3D printing is a flat, multi-layered substrate printed beneath the main part to maximize bed adhesion and minimize warping—especially useful for materials like ABS or on uneven build plates. Rafts ensure prints remain fixed throughout the process but use about 30 % more filament compared to skirts or brims. While rafts provide the best adhesion, they can degrade the bottom surface finish and extend print times. In contrast, skirts use the least material and time but offer no bed adhesion benefit. Brims strike a balance, slightly increasing adhesion and material use. [1][2][3]

Historical Background

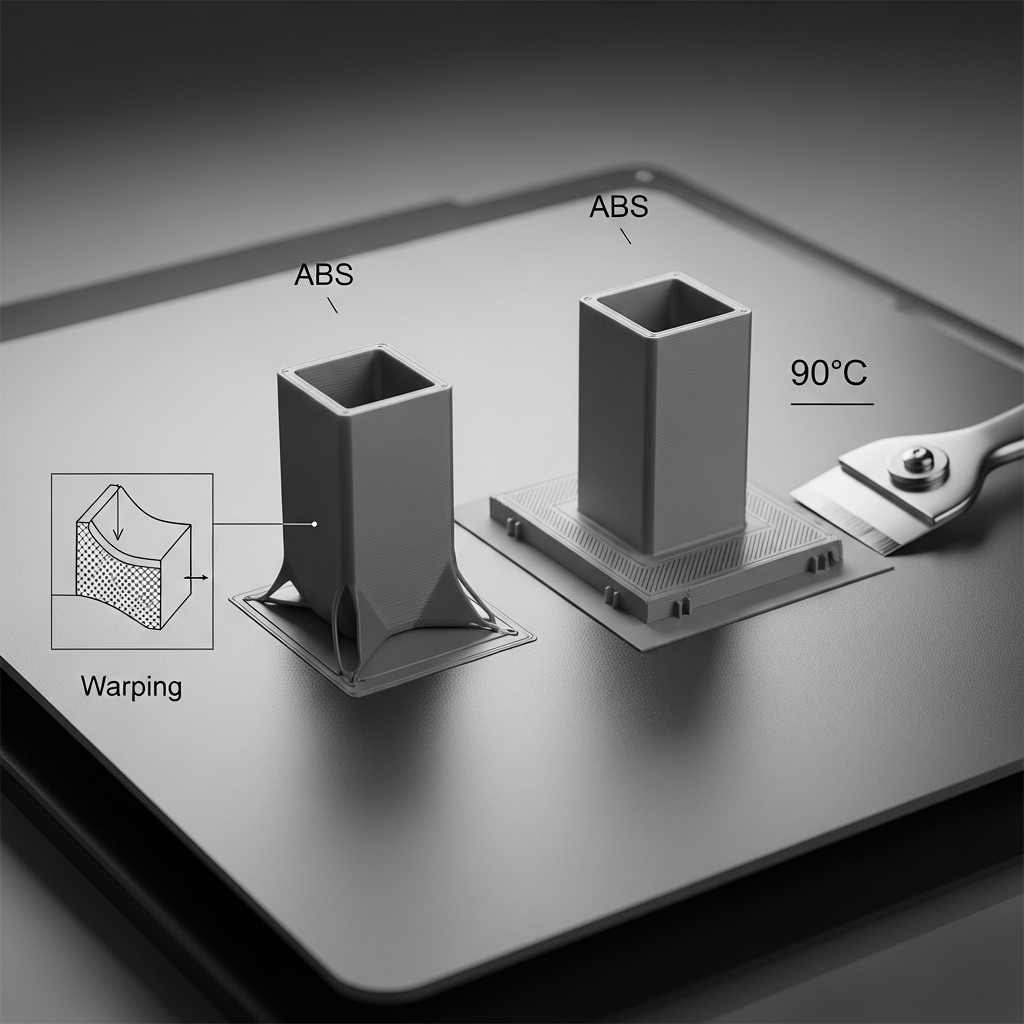

The raft technique emerged with early extrusion-based 3D printing (fused deposition modeling) to help print ABS with high warping. No reliable figure is found for year or inventor, but rafts remain foundational in adhesion strategy despite advances in surfaces. [7]

Technical Principles

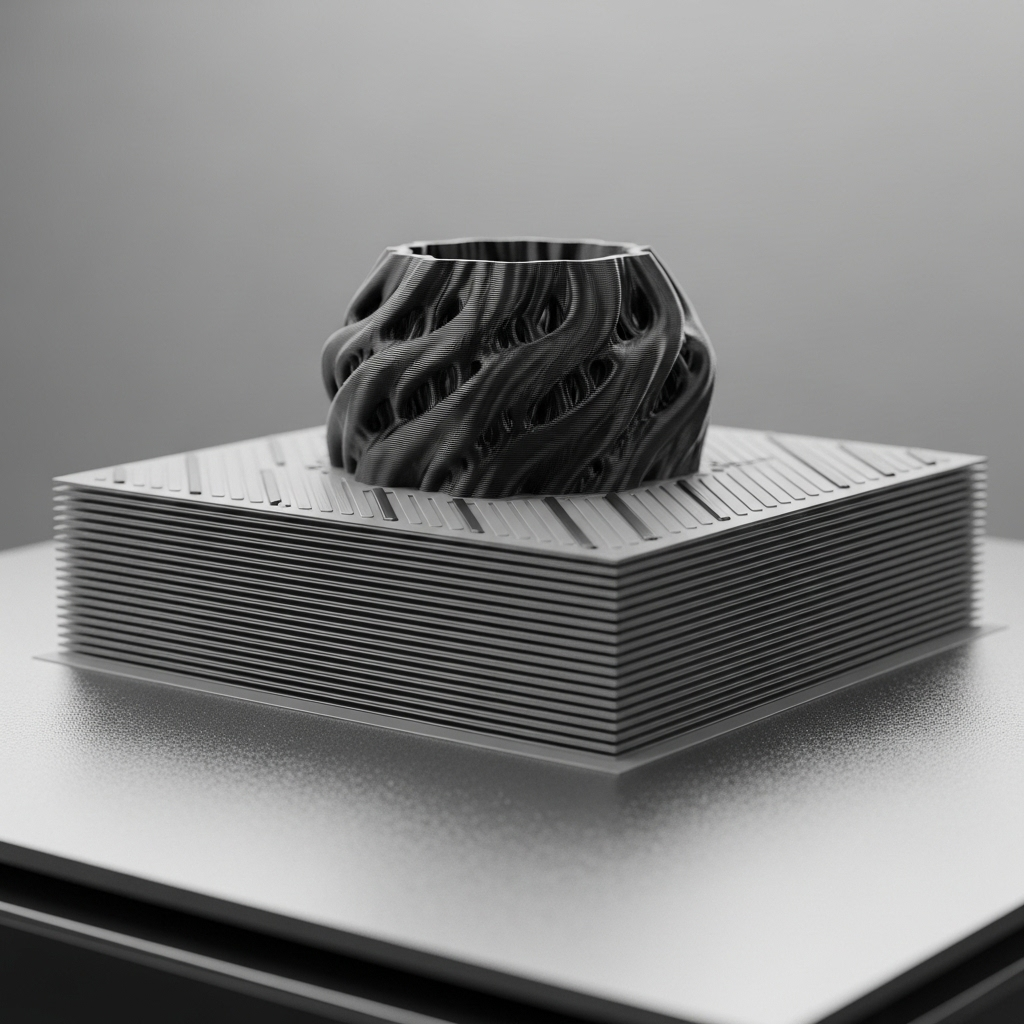

A raft consists of 3–6 printed layers that form a platform under the actual part, intended to provide reliable bed adhesion, compensate for build plate irregularities, and facilitate print removal. Rafts separate from the part with a defined “air gap”—typically 0.3 mm—to simplify cleanup. Rafts also extend beyond part boundaries, with an extra margin of 10–20 mm for stability. Unlike a brim, which expands only the initial solid layer outward, or a skirt, which prints lines around the part for priming, the raft fully isolates the print from the build plate and maximizes contact. [3][8]

Types and Comparison

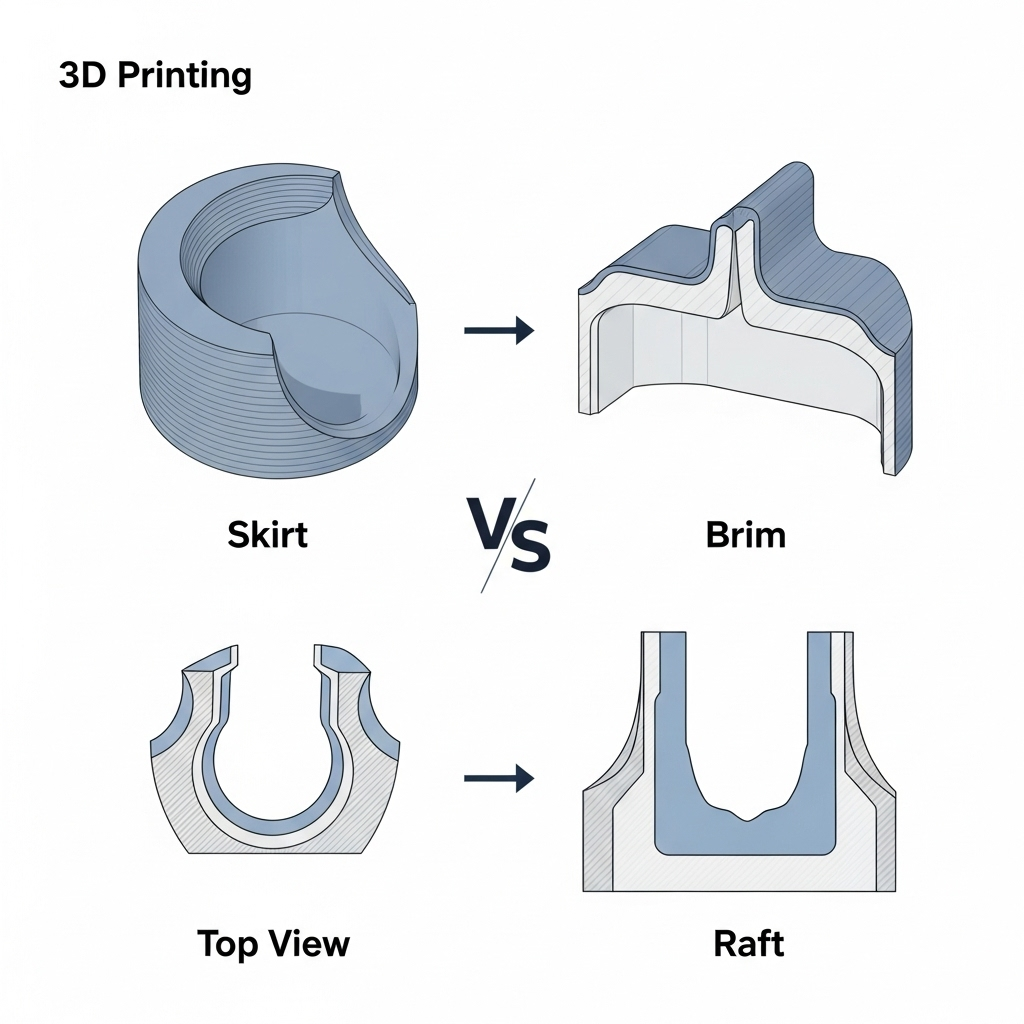

A skirt is a perimeter line drawn around a part to prime the nozzle and check bed level, not to improve adhesion. A brim extends outward from the first layer of the part by 3–8 mm, increasing bed contact and aiding adhesion. A raft creates an entirely separate base platform beneath the part for maximum adhesion and a flat foundation. [2][4]

The three build plate adhesion methods involve clear trade-offs. Skirts use the least filament and are fastest but do not address adhesion problems. Brims moderately boost adhesion and use more material, while rafts—although resource-intensive—offer robust adhesion on challenging surfaces or with materials prone to warping.

Pros and Cons:

- Skirt:

- Pros: Fastest, minimal filament, easy setup

- Cons: No adhesion benefit

- Brim:

- Pros: Enhanced adhesion (3–8 mm extra), helps nozzle priming

- Cons: Slightly more material, more cleanup

- Raft:

- Pros: Maximum adhesion, best for problematic beds/materials

- Cons: +30 % material, longer print time, tougher removal, rougher base finish

| Method | Material Use | Adhesion Strength | Removal Difficulty | Print Time |

|---|---|---|---|---|

| Skirt | Minimal | None | Easy | Shortest |

| Brim | Moderate (3–8 mm) | Moderate | Easy–Medium | Moderate |

| Raft | ~30% more | Maximum | Difficult | Longest |

| [1][2][3][5][6] |

Applications

Rafts are most beneficial when printing ABS, dealing with a warped or unlevel build plate, or producing small-footprint objects that risk detachment. The raft minimizes warping and guarantees secure adhesion where the default print bed surface contact would be unreliable. They are widely recommended for beginners tackling adhesion with difficult materials or for critical prints where failure is costly. Brims are typically preferred for PLA or when a small boost in adhesion suffices, whereas skirts suit parts with strong built-in adhesion or when only nozzle priming is desired. [5][7]

Slicer Settings

Key slicer parameters for rafts and brims include raft layer count (3–6), air gap (~0.3 mm), raft margin (10–20 mm), and brim width (3–8 mm). These values strike a balance between easy removal, enhanced adhesion, and minimal filament waste. [3][6][8]

Research Updates

No reliable quantitative scientific studies are available comparing the exact adhesion improvement between rafts, brims, and skirts. Most advice is based on technical guidelines and user reports; the industry acknowledges a lack of published laboratory data. [2]

Q&A (FAQ)

-

What is a raft in 3D printing?

A raft is a multi-layered platform printed beneath the main model for maximum bed adhesion, especially helpful for warping materials or uneven surfaces. [3] -

When should I use a raft vs skirt or brim?

Use a raft when printing ABS, with small contact areas, or on warped beds; use skirts for nozzle priming and brims for minor adhesion help with minimal cleanup. [5][7] -

How much more filament does a raft use than a skirt or brim?

A raft consumes around 30 % more filament compared to skirts or brims, making it the most material-intensive build plate adhesion method. [1] -

What slicer settings (air gap, margin) optimize raft removal?

Use an air gap of about 0.3 mm and set a raft margin of 10–20 mm. These parameters help separate the print from the raft without compromising adhesion. [8] -

Will using a raft improve adhesion on warped beds or ABS prints?

Yes. Rafts provide the strongest bed adhesion, which is extremely valuable with ABS filament or on prints where the build plate is warped or damaged. [7] -

Does a raft negatively affect the bottom surface finish or dimensional accuracy?

Rafts can make the part’s bottom rougher and impact dimensional accuracy due to the extra interface between raft and part, especially if settings are not optimized. [5]

Sources

- 3D Mag — Brim vs Raft 3D Printing Adhesion Methods

- 3D Realize — Differences Between Skirt, Brim, and Raft

- fypower — Raft vs Brim vs Skirt

- Xometry — Skirt vs Brim vs Raft

- 3DSourced — Raft, Brim, or Skirt? Pros and Cons

- printingatoms — Brim vs Skirt vs Raft

- 3D Insider — Raft in 3D Printing

- 3D Mag — Brim vs Raft vs Skirt: Comparison