Summary

A brim in 3D printing is a single-layer, outward extension of the first layer that increases bed contact to improve adhesion and prevent warping, without forming a platform beneath the entire model as a raft does. Brims are most useful for moderately challenging prints and consume less filament than rafts, making them a practical choice when strong bed adhesion is needed but minimal material usage is desired. [1][2]

Historical Background

The concept of a brim emerged with the rise of fused deposition modeling (FDM) and fused filament fabrication (FFF) 3D printing, addressing persistent challenges with bed adhesion and first-layer warping. Its specific origin remains unverified, but brims quickly became standard in slicing software as a response to user demand for adhesion aids. [1]

Principles

Brims prevent warping and lifting during 3D printing by extending the contact area between the model and the print bed. This increased adhesion helps to secure the outer edges, counteracting forces that would otherwise cause the part to curl or detach. [1]

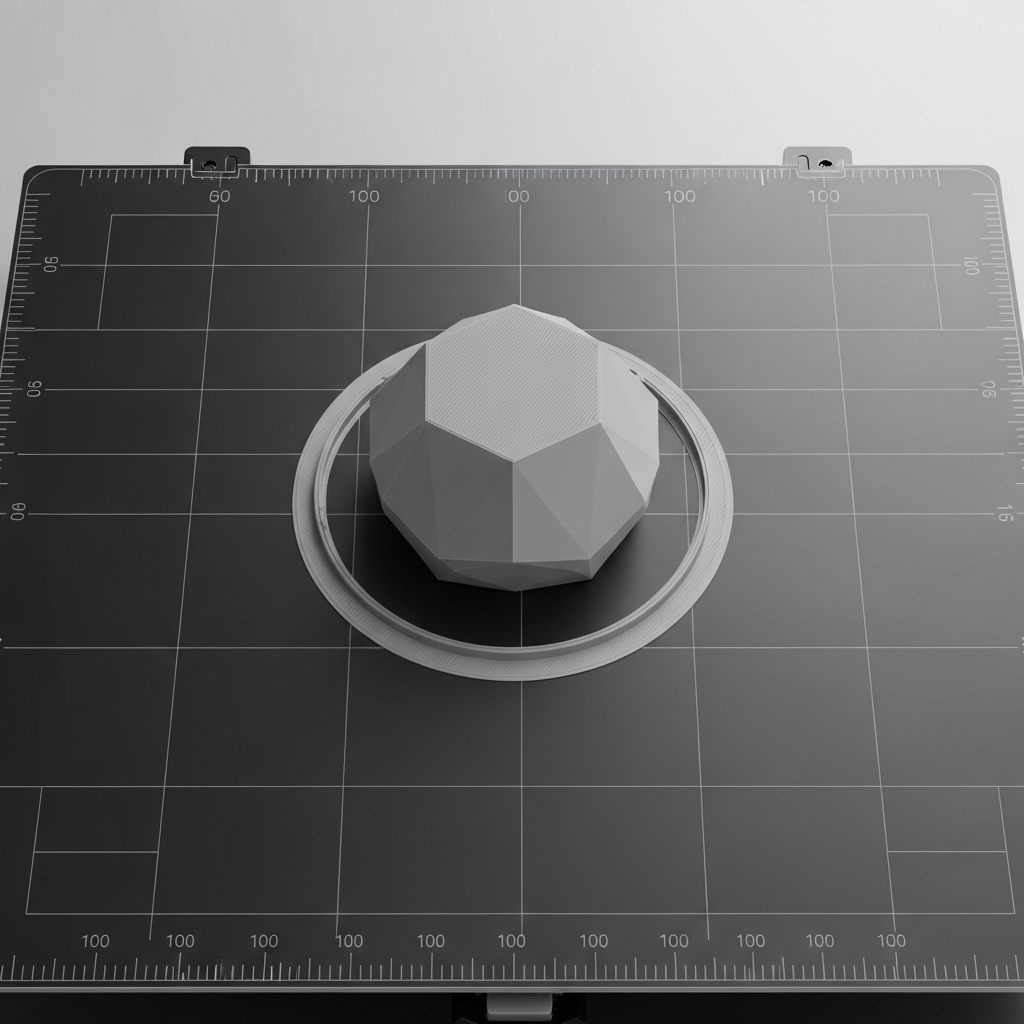

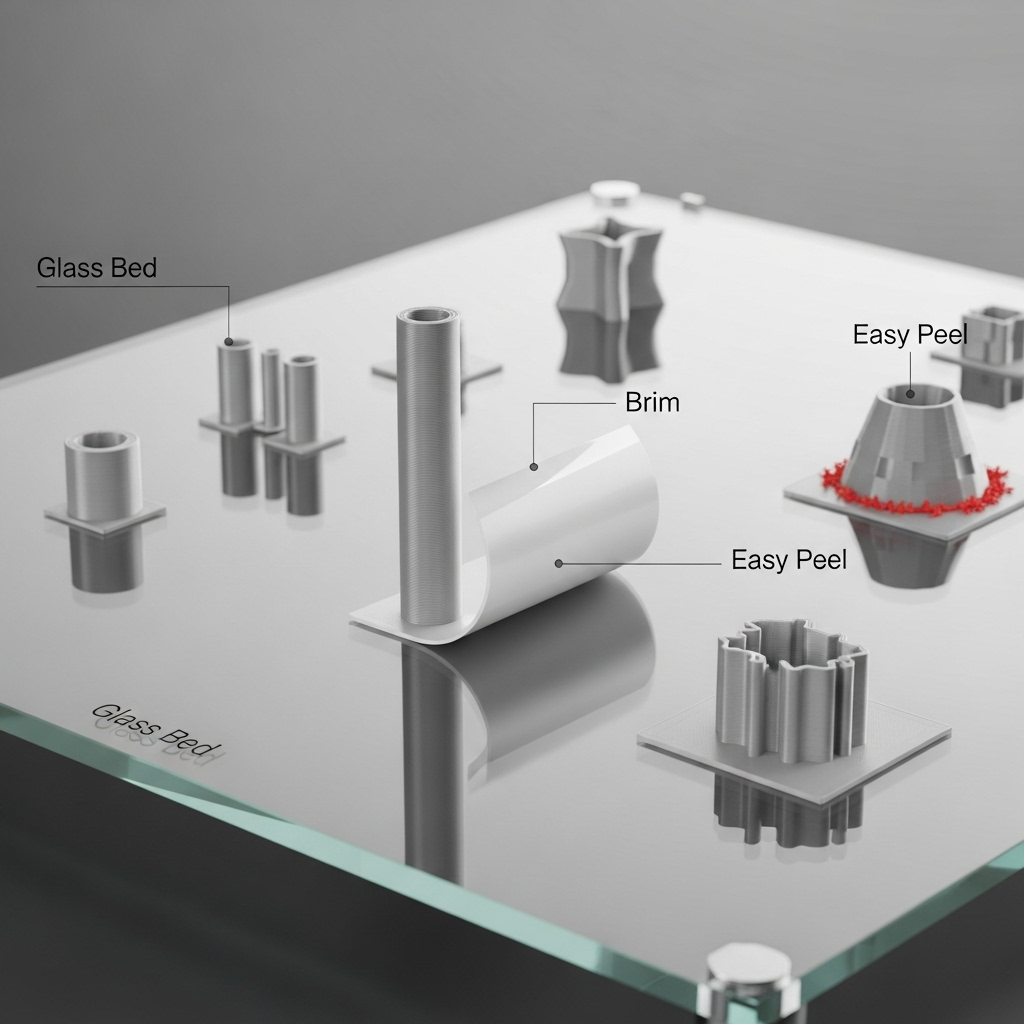

A brim is created as a single-layer perimeter that extends outward from the base of a print, typically by 3–8 mm beyond the model’s footprint. This temporary extension works by increasing the model’s surface area on the heated bed, which keeps the edges anchored as the print cools. It also helps “prime” the extrusion, ensuring consistent filament flow and reducing the risk of under-extrusion or first-layer gaps. Once the print is complete, the brim is removed by peeling or cutting away the added material, as it does not fuse to the model’s vertical walls. [4][7]

Types and Comparison

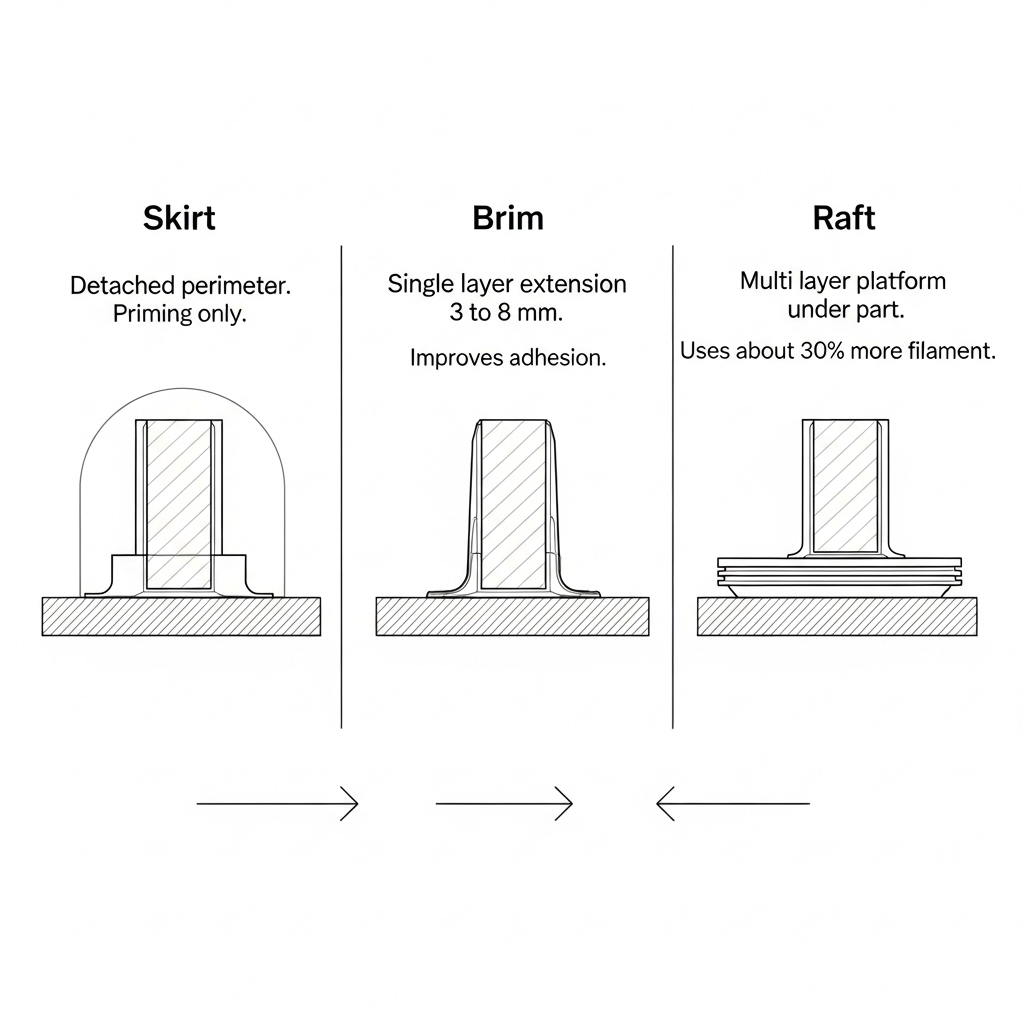

There are three main adhesion aids for the first layer: skirt, brim, and raft.

- Skirt: Outlines only the perimeter, detached from the part, used for priming but does not aid adhesion.

- Brim: Extends outward from the model’s base as a single layer, improves adhesion and combats warping.

- Raft: Forms a thick multi-layer platform under the print, offering maximum adhesion but at the cost of higher filament use and potential impact on bottom surface finish. [4][6]

Summary Table: Skirt vs Brim vs Raft

| Feature | Skirt | Brim | Raft |

|---|---|---|---|

| Material Usage | Minimal | Low | ~30% more than skirt/brim [3] |

| Adhesion Improvement | None | Good | Ultimate/very strong [6] |

| Removal Difficulty | None | Easy to moderate | Moderate to hard |

| Bottom Surface Finish | Not affected | Not affected | Can degrade surface quality |

| Dimensional Accuracy | No effect | May slightly reduce [5] | Can strongly reduce |

Pros and Cons:

- Brims: Pros—improves adhesion, uses little filament, easy to remove. Cons—may affect dimensional accuracy at base, requires cleanup.

- Rafts: Pros—“ultimate” adhesion, ideal for warped-prone or small-part prints. Cons—more filament used, lower surface finish quality, removal can be difficult.

- Skirts: Pros—fast, does not use extra material; cons—does not aid adhesion. [2][3][4][5][6]

Technical Performance

Brims use less filament than rafts and are generally faster to print, while a raft requires approximately 30 % more material than either a brim or a skirt. However, both brims and rafts can negatively affect the dimensional accuracy of the print’s base, with rafts having greater impact. [2][3][5]

Applications

Brims are recommended for prints with narrow bases, tall structures, or models prone to edge lifting, such as vertical cylinders or objects printed on glass for a smooth finish. Their material efficiency and ease of removal make them well-suited for scenarios where moderate adhesion is needed without the hassle or rough surface of a raft. Brims are also commonly used for materials with mild warping issues, such as PLA or PETG, and help initiate extrusion by stabilizing the first layer. [1][2]

In contrast, rafts are preferred for objects with small footprints, models made from highly warp-prone materials like ABS, or in cases where bed adhesion is particularly unreliable. The raft’s multi-layer structure provides the strongest foundation, at the expense of extra material, additional print time, and a sometimes rough bottom surface finish. [6]

Research Updates

No scientific studies documenting precise, numeric adhesion improvements from brims have been published to date. While technical guides and manufacturer documentation consistently report improved adhesion, no reliable figure has been found quantifying the exact performance benefit of adding a brim versus other adhesion aids.

Q&A (FAQ)

1. What is the difference between brim vs raft?

A brim is a single-layer extension from the print’s base that increases bed contact, using less filament and providing good adhesion. A raft forms a multi-layer platform below the print, offering the strongest adhesion but at higher material and time cost, and can diminish finish quality. [1][6]

2. How does a brim improve bed adhesion?

By increasing the contact area of the first layer, the brim holds down edges and prevents warping, making it less likely for prints to detach as they cool. [4]

3. When should you choose a 3D printing brim over a raft?

Choose a brim when your print needs moderate extra adhesion—such as tall, thin, or edge-prone models—without significantly increasing print time or material. Rafts are only necessary for the most challenging adhesion problems. [2]

4. Does printing a brim affect the accuracy of the print?

Yes, a brim can slightly impact the dimensional accuracy of the first layer since extra material may require careful removal and can occasionally disturb base dimensions if not cut cleanly. [5]

5. How much additional filament does a raft use compared to a brim?

A raft typically uses about 30 % more filament than either a brim or a skirt, due to its multiple layers below the print. [3]

6. Are there standard brim settings like width or line count?

The typical brim width is between 3–8 mm, though some slicers allow you to set the number of perimeter lines instead. Optimal settings depend on your model and printer. [7]

Sources {#sources}

- 3D Insider — Brim vs Raft in 3D Printing

- 3D Insider — Rafts, Skirts, and Brims Explained

- FYPoWER: Raft vs Brim vs Skirt Comparison Guide

- 3D Realize — Skirt, Brim, and Raft Differences

- FacFox — Raft vs Brim vs Skirt: The Differences

- 3D Insider — Rafts, Skirts, and Brims Comparison

- FYPoWER — Brim Tips and Width Advice