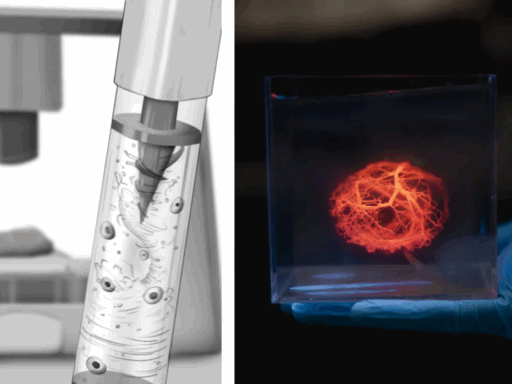

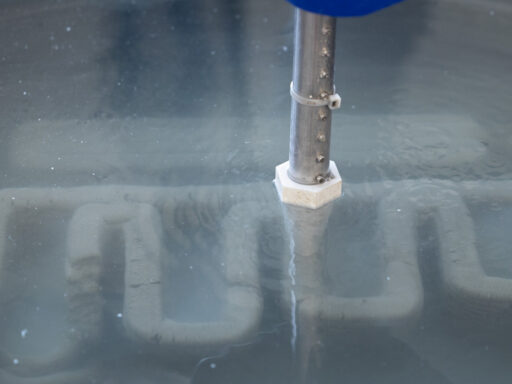

In a new collaboration, Bambu Lab and Presq, a Los Angeles-based design-tech studio, are reshaping the limits of possibilities in 3D printing. The partnership resulted in Fig.(0), an open-source, entirely 3D-printable shoe design that gives makers full creative control over their customized footwear.

Most leading brands like Nike, Adidas, and ASICS have experimented with 3D-printed shoes before, but their designs remain accessible only within proprietary systems. The Bambu Lab-Presq project breaks all expectations by making every design file openly available for download (check out Fig.(0) on MakerWorld), remixing, and personal experimentation.

“By pairing Bambu’s performance with our design system and creative direction, we’re giving creators a practical path from imagination to a real product people can wear,” said Adam Saleh, Presq’s Founder & CEO. “And we’re doing it in a way that keeps cultural value closer to the communities that create it.”

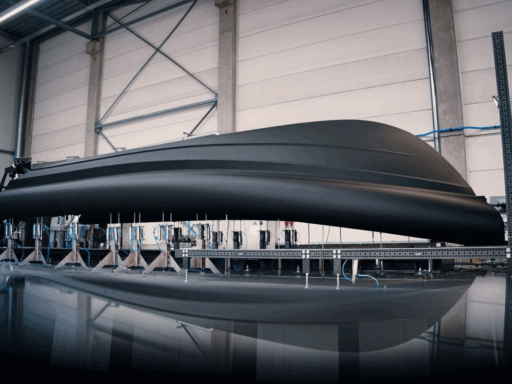

The Fig.(0) release features a U.S. men’s size 10 base model, accompanied by a scaling table for other sizes, a pre-sliced .3mf file, already optimized for Bambu H2D printers, and the full CAD source for creative modification. The design utilizes matte TPE 85A as the primary material, complemented by PLA, which makes it durable and allows for an easy tidy-up, resulting in a sleek, wearable finish.

Presq describes the project as a bridge between “prompt-to-product” workflows and culturally resonant design. It’s an experimental approach, democratizing not just the tools of production, but also the everyday aesthetics.

This collaboration marks a step toward real, practical, and functional fashion. Presq plans to release new open-source styles every month, inspiring makers across the globe to walk in their own creations.