Summary

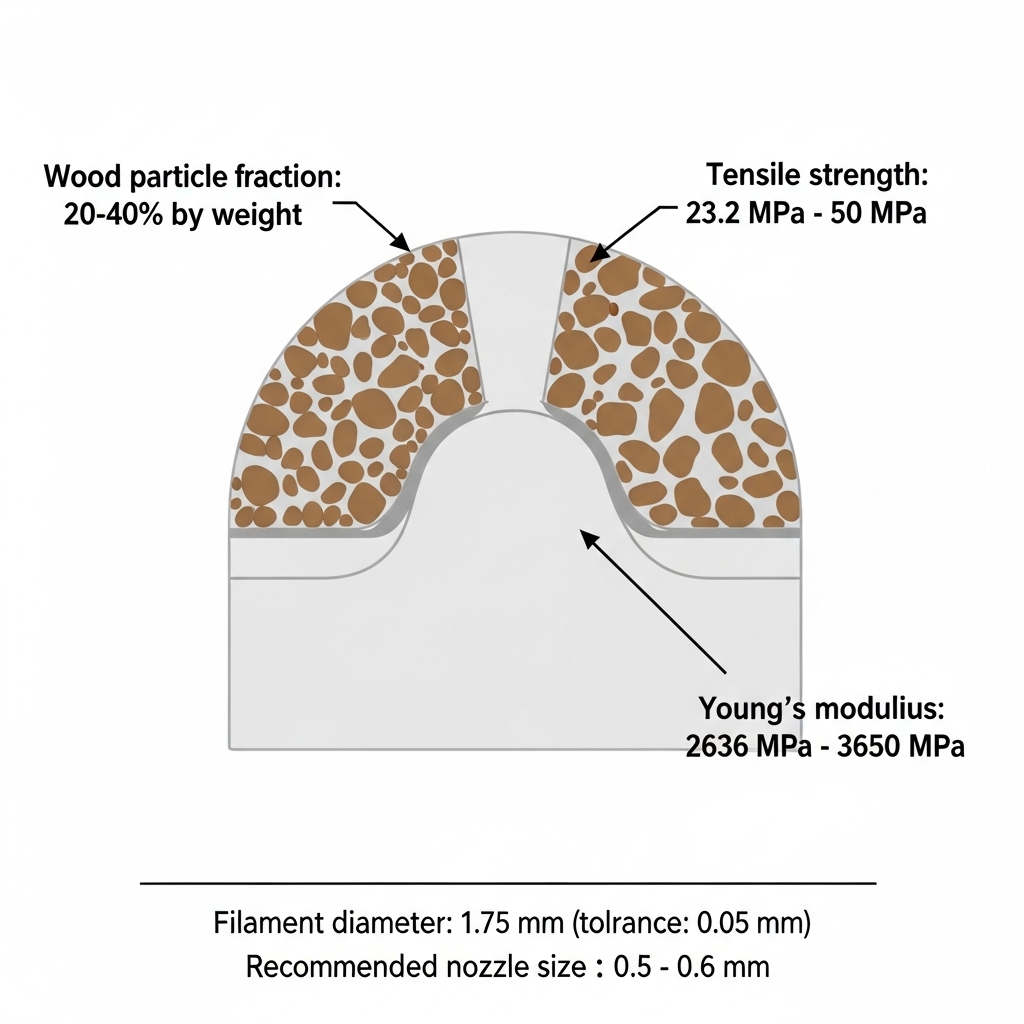

Wood filament, also known as wood PLA or wood-infused PLA, is a composite 3D printing material that typically combines 20–40 % wood particles by weight with polylactic acid (PLA) polymer. This blend imparts a natural look and wood-like texture to 3D prints while retaining the processability of standard PLA. Wood filaments are especially valued for their aesthetic qualities and tactile finish but generally have lower mechanical strength compared to conventional PLA. Published tensile strengths range from about 23.2 MPa to 50 MPa, with stiffness roughly 2,636–3,650 MPa, and print diameter tolerances as tight as ± 0.05 mm. [1] [2] [3] [4] [5] [6] [7] [8]

Historical Background

The first commercially available wood filament for 3D printing, known as Laywood‑D3, was introduced by Kai Parthy in 2012 through the Thingiverse maker community in Germany. Its principal aim was to provide desktop 3D printing with a visually authentic, wood-like finish for aesthetic modeling projects. [2]

Technical Principles

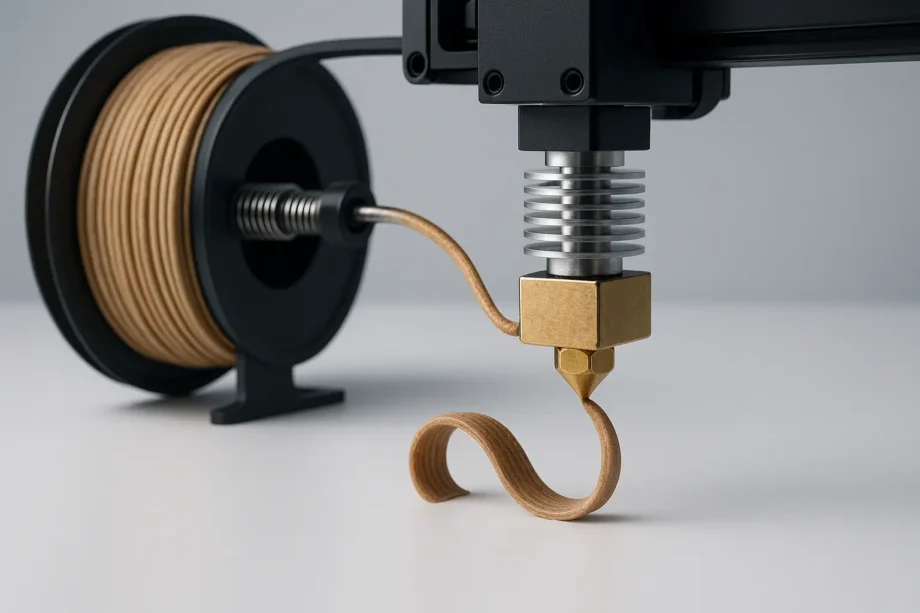

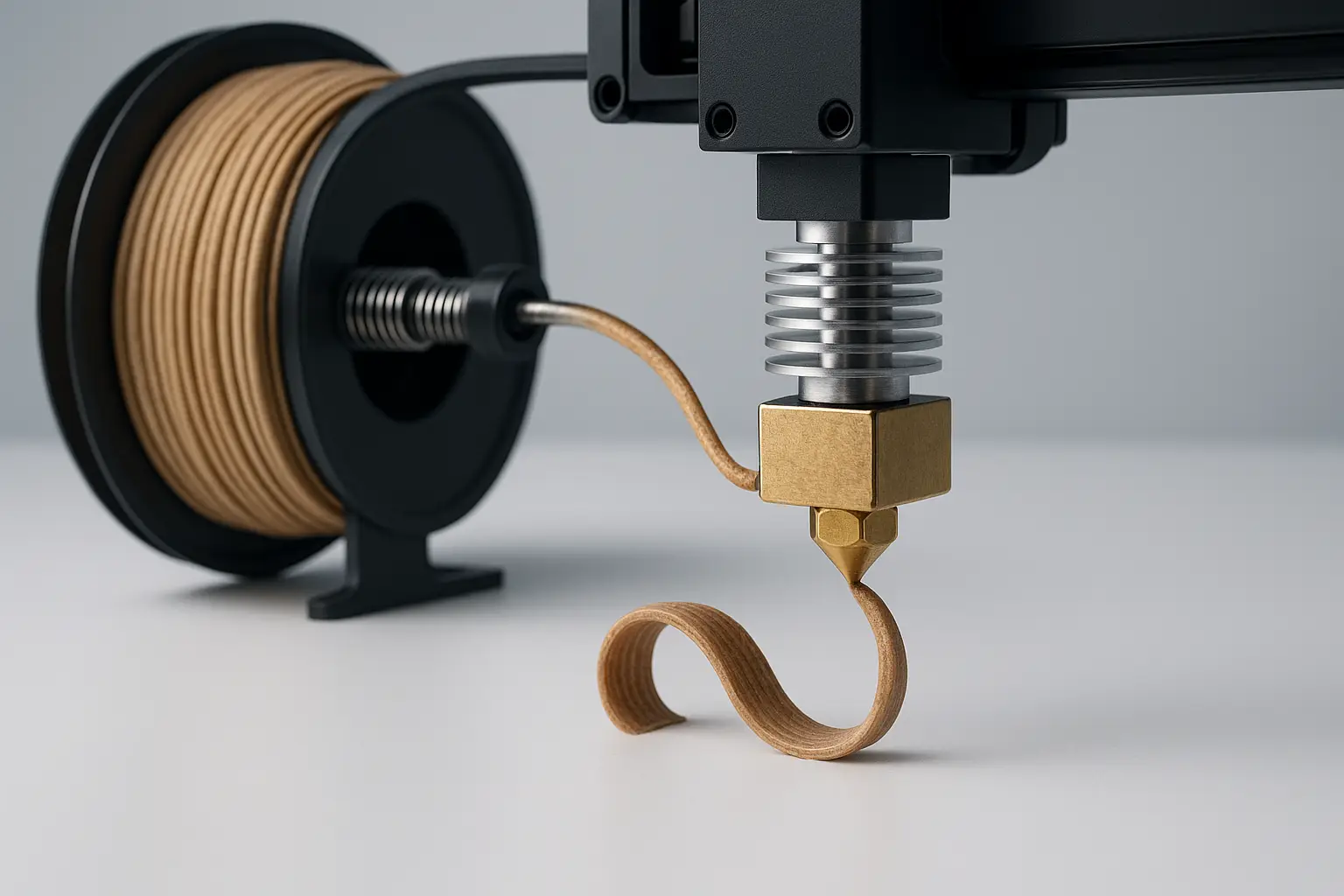

Wood filament is a composite that consists of PLA blended with natural wood fibers or particulates in the range of 20–40 % by weight. This material composition directly influences both tactile and visual characteristics, resulting in prints that mimic real wood in color and grain. Prints may even emit a woody scent during fabrication, but can also be more brittle than standard PLA. [1] [5]

Key composite and printing effects of wood PLA include:

- Enhanced surface texture and unique grain patterns

- Aroma reminiscent of natural wood during and after printing

- Reduced flexibility, increased brittleness compared to pure PLA

- Increased risk of nozzle clogging with smaller diameters [1]

For successful 3D printing of wood filament, specific adjustments are required. A nozzle diameter of at least 0.5 mm — preferably 0.6 mm for wood-rich blends — is essential to prevent clogging from wood particles. Wood PLA generally enables minimal warping or shrinkage relative to ABS, but its organic fillers can accelerate nozzle abrasion and require careful print parameter tuning. [5] [7] [2]

A typical list of printing considerations:

- Minimum recommended nozzle: 0.5–0.6 mm

- Print temperature: ~205 °C (range: 190–220 °C)

- Heated bed not essential (recommended ≤ 60 °C)

- Moderate printing speed (100–200 mm/s commonly used) [5] [7]

Performance

Mechanical Properties

Mechanical behavior differs between commercial sources. For example, Snapmaker Wood PLA displays a Young’s modulus of 2,636 ± 330 MPa, tensile strength of 23.2 ± 0.4 MPa, and impact strength of 2.7 ± 0.2 kJ/m². In contrast, Xometry tests report a tensile modulus of 3,650 MPa and yield strength around 50 MPa — indicating significant variability based on formulation and testing methodology. Both sources agree: wood filament is less ductile than standard PLA, with a reduced elongation at break (around 3.8 %). [6] [8]

Comparison Table: Snapmaker vs. Xometry Wood Filament Properties

| Property | Snapmaker Wood PLA | Xometry Wood-Filled PLA |

|---|---|---|

| Young’s Modulus (MPa) | 2,636 ± 330 | 3,650 |

| Tensile Strength (MPa) | 23.2 ± 0.4 | ~50 (yield) |

| Flexural Strength (MPa) | 52.9 ± 0.3 | ~14.47 |

| Impact Strength (kJ/m²) | 2.7 ± 0.2 | ~5.1 |

| Elongation at Break (%) | Not stated | ~3.8 |

| Glass Transition (°C) | 62 | ~45 |

| Melting Temp (°C) | 151 | 130–210 |

| [6] [8] |

Dimensional & Flow Precision

Most wood-infused PLAs are manufactured to a filament diameter of 1.75 mm with a tight tolerance, such as ± 0.03 mm for 3DTrček’s WOOD PLA. Snapmaker states an achievable dimensional accuracy of ± 0.05 mm on finished prints. Wood PLA can be printed at speeds between 60 and 300 mm/s, with a typical range of 100–200 mm/s, and a volumetric flow between 12–25 mm³/s. [3] [4] [6]

Thermal and Print Conditions

The recommended printing temperature falls around 205 ± 15 °C, with nozzle sizes of at least 0.5–0.6 mm and maximum bed temperatures of 60 °C. Reported glass transition temperatures range from ~45 °C to 62 °C, and melting points are between 130 and 210 °C, depending on the specific formulation and source. [5] [6] [8]

Applications

Wood PLA is primarily used for producing objects that emphasize aesthetic and decorative appeal. This includes architectural models, figurines, decorative panels, interior accents, and props. Parts made from wood filament can be sanded, stained, or finished using conventional wood-working techniques for enhanced realism and texture. Wood PLA’s ability to replicate the grain and texture of real wood broadens its appeal for creative and display-centric projects. [1] [8]

Main use cases for wood PLA:

- Concept models and architectural prototypes

- Art pieces, props, and collectible figures

- Decorative home and office objects

However, wood-infused PLA is not suited for load-bearing or structural applications. Limitations include increased brittleness, susceptibility to moisture absorption (leading to swelling or print defects), and accelerated nozzle wear from both wood particles and required nozzle size. It is less durable than pure PLA and should not be used where high strength, high heat resistance, or weather tolerance are required. [1] [2] [4] [8]

Key limitations of wood PLA:

- Brittle and prone to cracking

- Absorbs atmospheric moisture, risking print errors

- Accelerated nozzle abrasion, especially with high wood content

- Not suitable for outdoor or mechanical parts

Research Updates

Recent research has seen the introduction of experimental PLA blends using agricultural byproducts. Notably, peanut hull–PLA composites are being studied for antimicrobial properties. These blends reportedly preserve elastic modulus but generate additional microvoids, which can impact final part density and strength. This trend points to further development of functional, eco-friendly natural look filaments that may offer more than just aesthetic benefits. [9]

Q&A (FAQ)

1. What is wood PLA, and how does it differ from standard PLA?

Wood PLA is a 3D printing filament composed of standard PLA blended with natural wood fibers (20–40 %), which imparts a wood-like texture, appearance, and aroma, but makes the filament more brittle than conventional PLA. [1]

2. What percentage of wood content is typical in wood-infused PLA filaments?

Most commercial wood PLA filaments are made with 20–40 % wood particles by weight, depending on the manufacturer and product line. [1] [7]

3. Why are larger nozzles (≥ 0.5 mm or 0.6 mm) recommended for wood filament printing?

A nozzle diameter of at least 0.5 mm — often 0.6 mm for high wood-loaded filaments — is needed to avoid clogs caused by wood particles suspended in the PLA base. [5] [7]

4. What are the mechanical limitations of wood filament compared to pure PLA?

Wood filament is generally weaker and more brittle, with lower tensile strength and impact resistance due to organic filler content and resulting microvoids, making it unsuitable for structural loads. [6] [8]

5. How do wood filament thermal properties like glass transition and melting temperature affect print behavior?

Typical glass transition temperatures (45–62 °C) and melting points (130–210 °C) mean that wood PLA prints have moderate heat resistance, similar to pure PLA, but remain vulnerable to warping or softening at relatively low temperatures. [5] [6] [8]

6. Are there innovations combining wood filament properties with antimicrobial function?

Yes. Novel PLA blends with peanut hulls confer antimicrobial properties, maintaining elastic modulus but at the cost of increased microvoids in finished parts. [9]

Sources

- Hi3DP: 3D Printing Filament — Wood Filament

- Wired: 3D Printer Wood Filament

- 3DTrček: WOOD PLA Technical Data

- 3DTrček: WOOD PLA Data Sheet

- Filamentive: Wood PLA Product Data

- Snapmaker: Wood PLA Filament Specs

- Smartmaterials3D: Smartfil Wood Data Sheet

- Xometry: All About Wood 3D Printing Filament

- arXiv: Peanut Hull–PLA Composite Filaments with Antimicrobial Effects