Summary

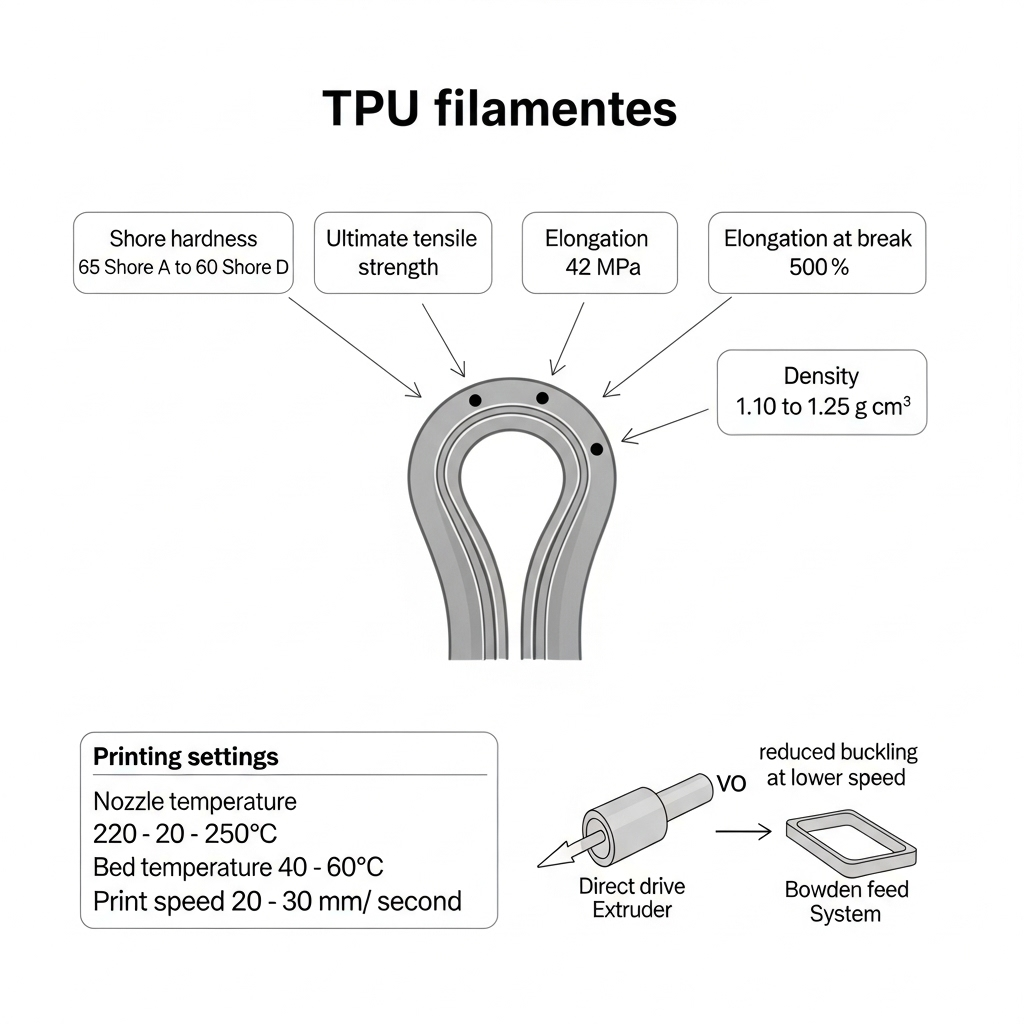

Thermoplastic polyurethane (TPU) is a flexible filament widely popular in 3D printing for its unique blend of elasticity, toughness, and durability. Exhibiting a Shore hardness range from 65 Shore A to 60 Shore D, TPU provides considerable flexibility while maintaining robust mechanical performance — with some variants achieving an ultimate tensile strength of 42 MPa and an elongation at break of 500 % (tacticalcnc.com). TPU’s versatility, however, comes with printing challenges such as a need for slow print speeds (20–30 mm/s) and careful temperature management (220–250 °C at the nozzle, 40–60 °C on the bed) (the3dprinterbee.com). These features make TPU an adaptable and practical choice for producing functional, flexible components.

Historical Background

TPU was first invented by Charles S. Schollenberger at B.F. Goodrich, who patented the material in 1952 and later introduced the Estane brand in 1958 (en.wikipedia.org). The material was officially recognized as invented in 1959 by Lubrizol/B.F. Goodrich, designed to combine the flexibility of rubber with the resilience of metal (plasticstoday.com).

Technical Principles

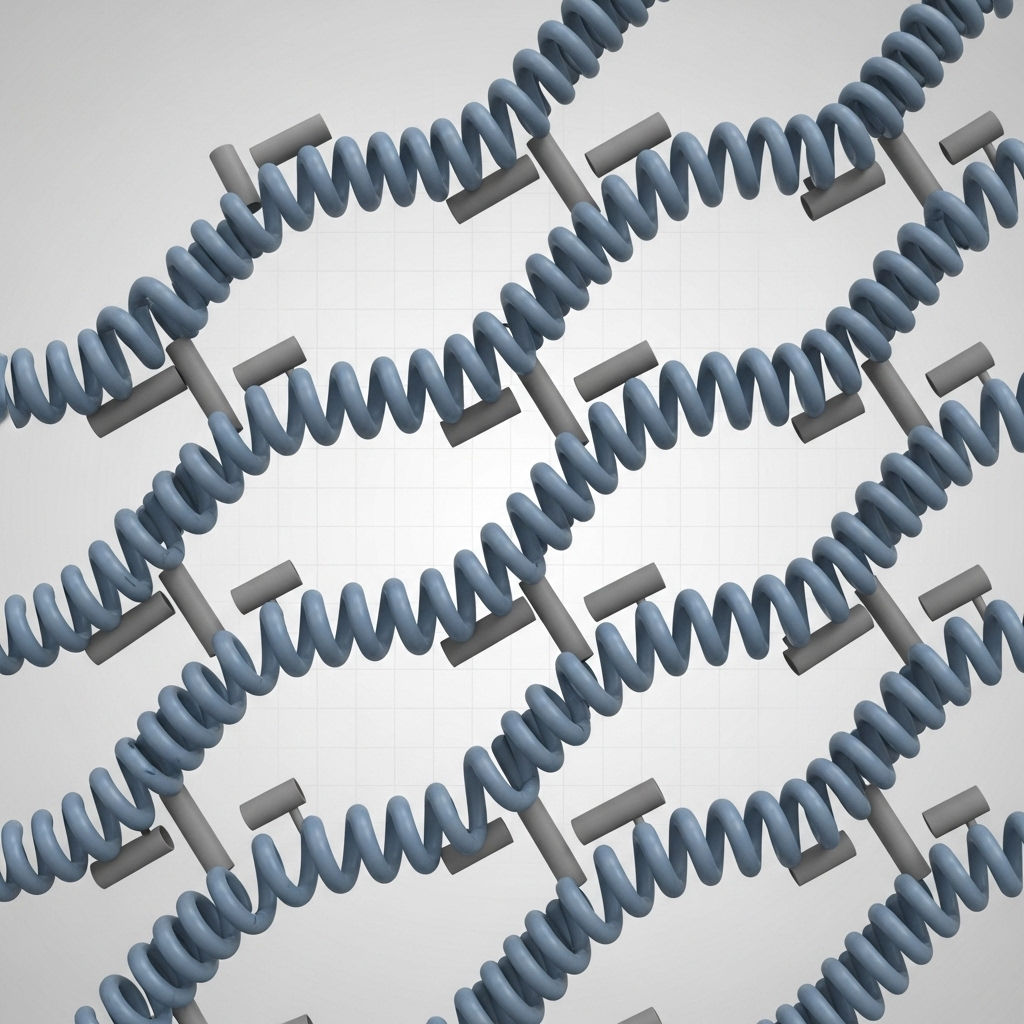

TPU is a member of the thermoplastic elastomer (TPE) family, distinguished by its block-copolymer molecular structure comprising alternating soft and hard segments. The soft phase imparts elasticity, while the hard phase gives the polymer mechanical strength and temperature stability. This dual-segment design allows TPU to behave like vulcanized rubber at room temperature, while still enabling it to be formed and reshaped repeatedly upon heating. The unique block-copolymer nature underpins TPU’s balance of flexibility and strength, favoring its use for applications demanding both properties (en.wikipedia.org).

A central advantage of TPU is its thermoplasticity — it can be reprocessed and recycled by melting and reforming, unlike traditional thermoset rubbers, thus offering both cost benefits and sustainability (en.wikipedia.org).

Performance

TPU’s mechanical and physical properties are pivotal to its widespread adoption in 3D printing. Key performance metrics include:

- Shore hardness: 65 Shore A to 60 Shore D, covering soft flexible to semi-rigid grades (tacticalcnc.com)

- Ultimate tensile strength: 42 MPa for certain formulations, indicating strong resistance to pulling forces (tacticalcnc.com)

- Elongation at break: 500 %, signifying remarkable stretchability before rupture (tacticalcnc.com)

- Density: 1.10 to 1.25 g/cm³, which affects part mass and buoyancy (the3dprinterbee.com), (3dprint.infomir.eu)

- Dimensional tolerances: ± 0.6 mm (X/Y) for parts under 80 mm, ± 1.8 mm (Z) (3dprint.infomir.eu)

This performance spectrum enables TPU to function in dynamic, load-bearing roles where conventional rigid plastics would crack or fail.

Research into TPU blends has revealed that when mixed with polylactic acid (PLA), the resulting composite experiences a notable reduction in strength (by 64 %) but a significant increase in ductility — up to 900 % depending on blend ratio. Such results highlight the critical influence of print parameters, including layer thickness and speed, with statistical analysis (ANOVA) confirming their notable effect on mechanical outputs (sciencedirect.com).

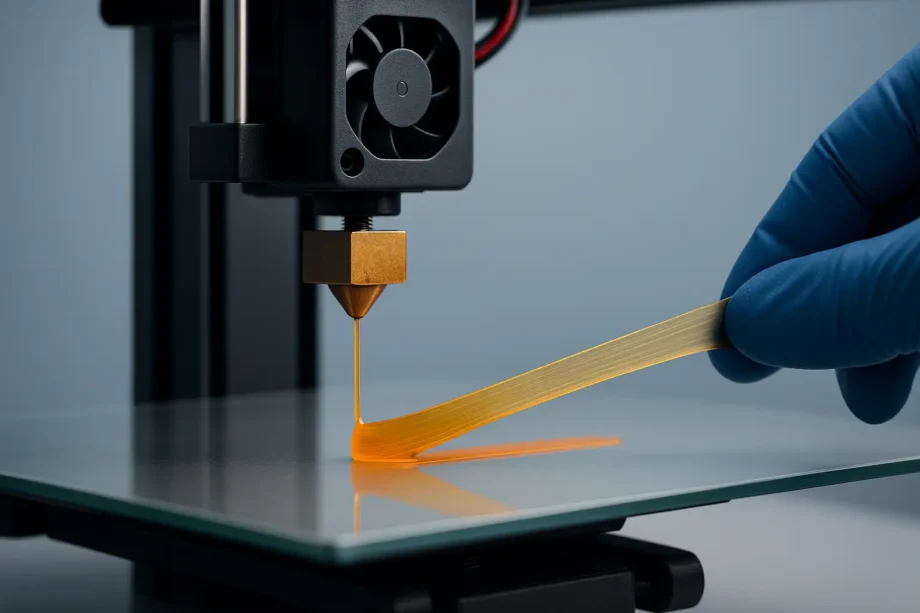

Printing Settings and Challenges

To achieve consistent prints with TPU, meticulous control of printer settings is paramount. Key recommendations include a nozzle temperature between 220 and 250 °C, a heated print bed set from 40 to 60 °C, and a reduced print speed of 20 to 30 mm/s to avoid filament buckling and ensure accuracy. Common challenges associated with TPU are stringing, inconsistent extrusion, and difficulties in feeding due to filament flexibility. Using a direct-drive extruder can help mitigate many of these issues (the3dprinterbee.com).

Recommended common settings:

- Nozzle temperature: 220–250 °C

- Bed temperature: 40–60 °C

- Print speed: 20–30 mm/s

Users often encounter pitfalls such as underextrusion or tangling when moving too quickly or using unsuitable Bowden-style extruders.

Applications

TPU is utilized in a variety of industries for objects requiring flexibility, robustness, and chemical resistance (en.wikipedia.org):

- Flexible smartphone cases

- Shoe soles

- Seals and gaskets

- Medical devices

Research Updates

Recent research efforts focus on advanced TPU composites. Photothermal titanium nitride (TiN)-TPU formulations can raise temperature approximately 2.5 times higher under infrared irradiation compared to standard TPU, promising for heat management (arxiv.org). Graphene-doped TPU (G-TPU) exhibits a remarkable in-plane (IP) thermal conductivity of 4.54 W/(m·K), an anisotropic thermal conductivity ratio of 8, puncture energy of 12.86 J, and a low friction coefficient (0.1). These enhancements position G-TPU as a candidate for flexible electronics and energy devices, further broadening the scope of TPU 3D printing applications (arxiv.org).

Q&A (FAQ)

-

What makes TPU suitable as a flexible filament for 3D printing?

TPU combines a broad Shore hardness range (65 Shore A to 60 Shore D), high ultimate tensile strength of 42 MPa, and exceptional elongation at break of 500 %, with its thermoplastic properties for easy processing (tacticalcnc.com). -

What print settings are recommended for TPU 3D printing?

Recommended parameters are a nozzle temperature of 220–250 °C, heated bed at 40–60 °C, and print speed of 20–30 mm/s (the3dprinterbee.com). -

How precise are TPU 3D printed parts?

Standard tolerances are ± 0.6 mm (X/Y) for parts under 80 mm and ± 1.8 mm (Z), reflecting material flexibility and printer calibration limitations (3dprint.infomir.eu). -

How does blending TPU with PLA affect mechanical properties?

Incorporating PLA reduces mechanical strength by 64 % but improves ductility up to 900 %, offering a trade-off between toughness and flexibility (sciencedirect.com). -

Expert-level: What photothermal benefits do TiN-TPU composites provide?

TiN-TPU’s photothermal conversion allows for a temperature rise of about 2.5 times compared to standard TPU when exposed to infrared, supporting applications in smart thermal management (arxiv.org). -

Expert-level: How does graphene enhance thermal and mechanical performance of TPU?

Graphene increases in-plane thermal conductivity to 4.54 W/(m·K), yields an anisotropic conductivity ratio of 8, raises puncture energy to 12.86 J, and drops friction coefficient to 0.1 (arxiv.org).