Summary

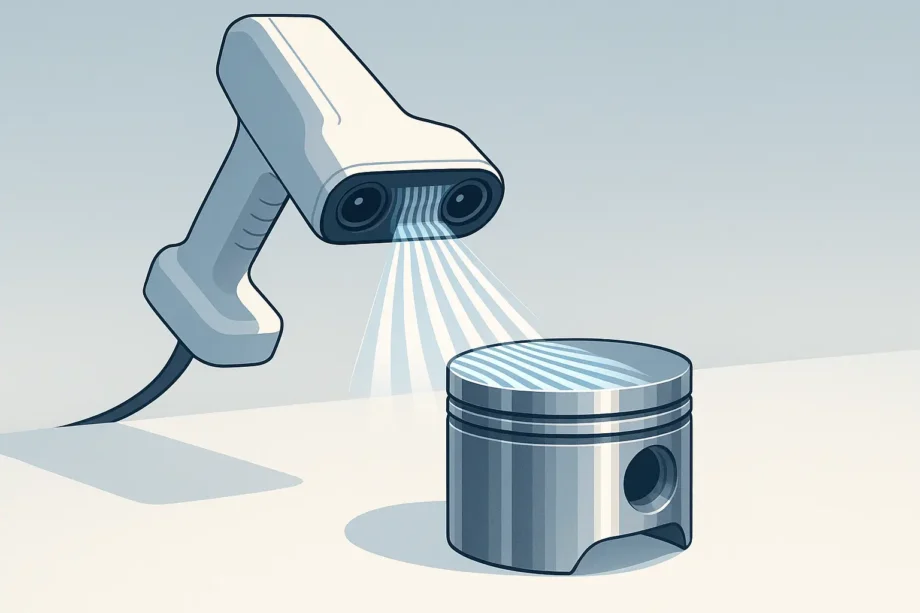

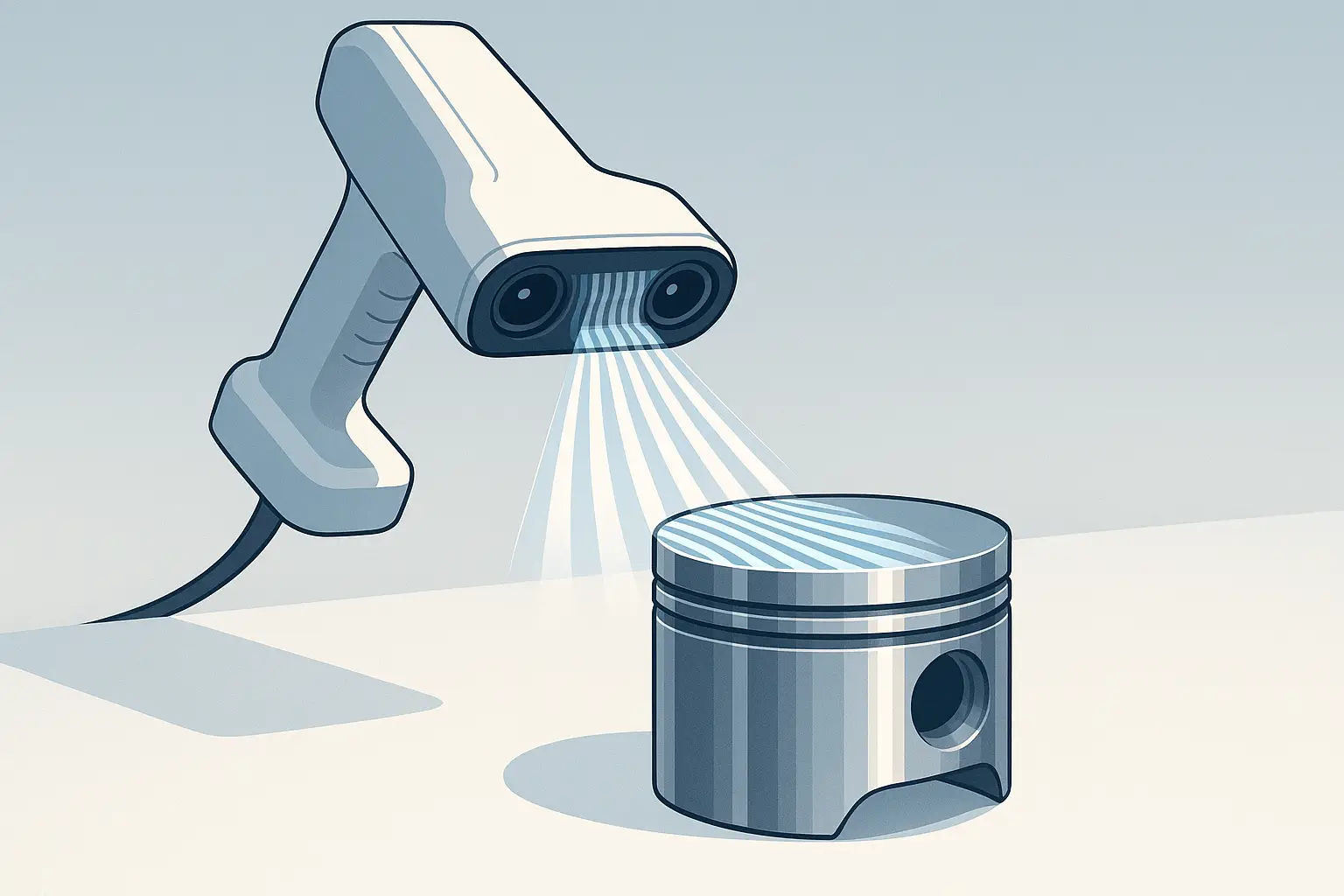

A structured‑light scanner is a fast 3D scan device that projects a known pattern — often stripes or grids — onto a surface and captures the deformation with cameras to reconstruct 3D geometry. Sometimes called a white light scanner or fringe projection scanner, this technology enables both rapid acquisition and high accuracy, with typical professional systems achieving 0.05–0.1 mm accuracy and research-grade setups reaching sub‑micrometre detail. Notable advantages of structured light 3D include its high precision, robust speed, and versatility for a wide range of objects and surfaces. [1] [2]

Historical Background

Structured light scanning originated in academic research during the mid‑1980s and 1990s, beginning with coded-light triangulation and evolving to use Gray‑code and phase‑shifting approaches to boost speed and precision. [1]

Technical Principles

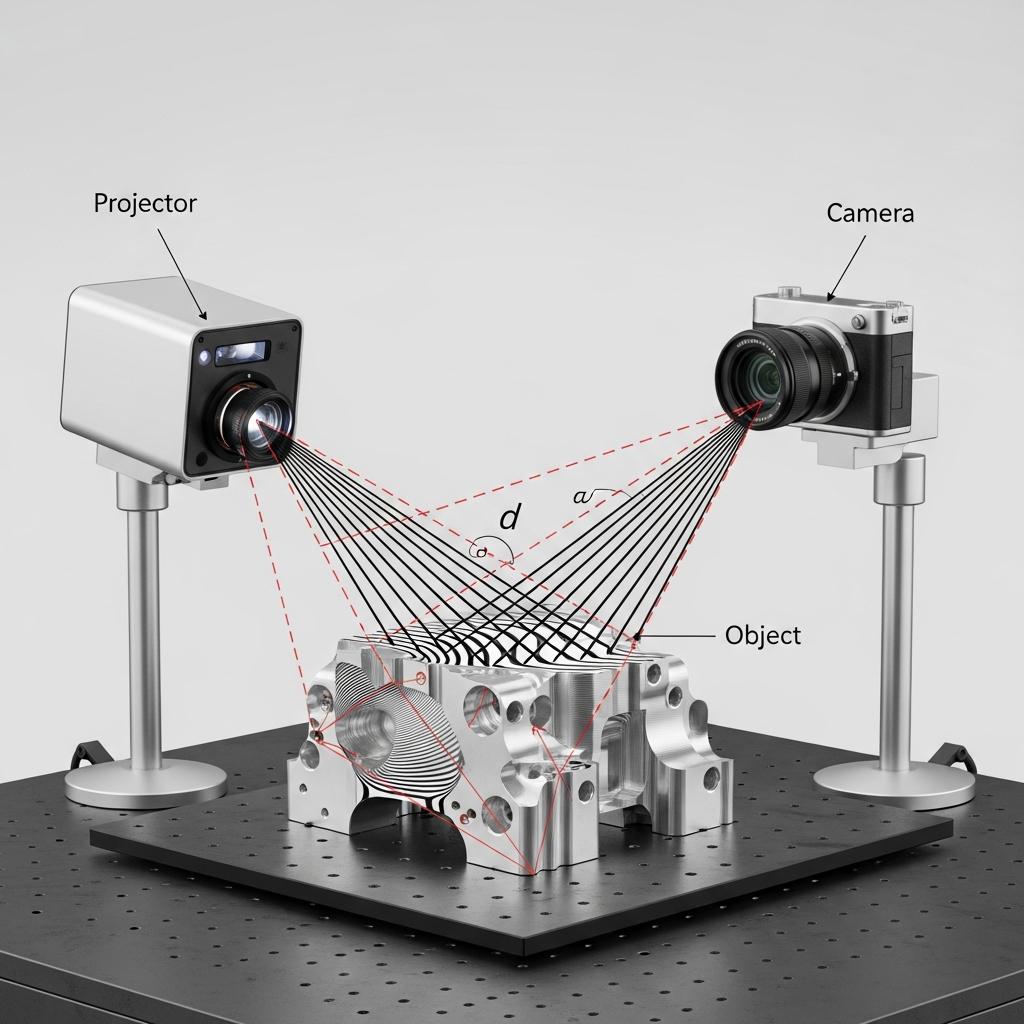

Structured‑light 3D scanners work by projecting specific light patterns — such as binary codes, Gray codes, or fringe patterns — onto an object’s surface. Cameras record the pattern’s distortion, allowing software to compute the surface’s 3D shape using triangulation techniques. [1]

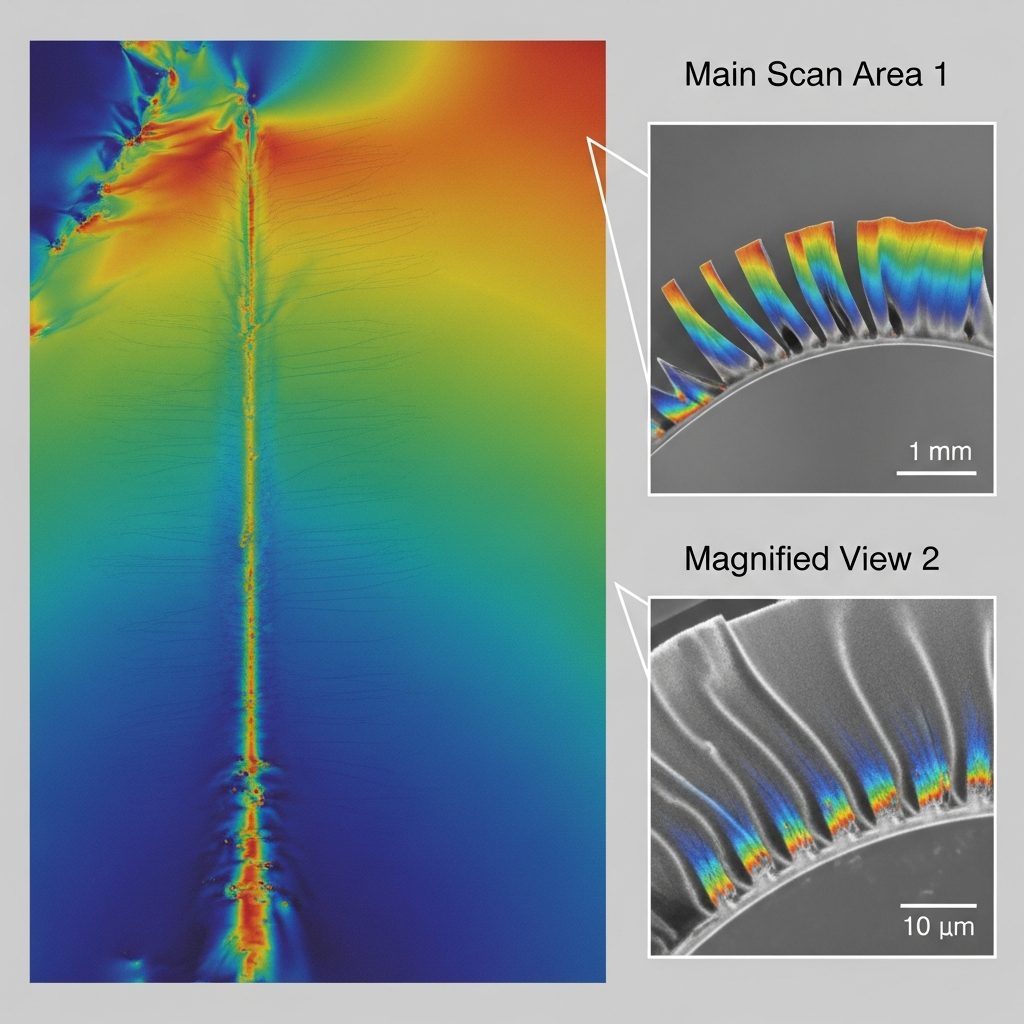

Precise calibration of projector and camera positions is essential, as are metrics like spatial resolution and measurement precision. State‑of‑the‑art systems can capture a two‑foot‑wide surface to 10 μm planarity, measure complex surfaces such as engine combustion chambers to 2 μm in elevation, or resolve blade edge radii with sub‑micrometre precision. Using phase‑shifting structured light, vertical resolution can reach 1/50 of a pixel, and lateral detail can approach less than 1 μm — roughly one‑tenth the width of a projected stripe. [1]

Types of Structured‑Light Scanners

Structured‑light scanners range from high‑end industrial rigs to accessible consumer handhelds. Popular professional models leverage white light scanning for portable, rapid capture while balancing accuracy and resolution. Notable examples include:

- Creaform Go!SCAN SPARK: accuracy up to 0.050 mm; volumetric accuracy = 0.050 mm + 0.100 mm/m; measurement resolution = 0.100 mm; scan rate = 1,500,000 measurements/s.

- Artec Eva Lite: accuracy up to 0.1 mm; resolution up to 0.2 mm; data acquisition speed up to 18 million points/s.

In-depth model comparisons with tabulated accuracy, resolution, and scan rate metrics are recommended for any full technical overview. [3] [4]

Performance

Typical professional structured‑light 3D systems deliver accuracy in the range of 0.05–0.1 mm, making them suitable for demanding metrology and quality assurance use. In highly specialized setups, such as blade edge metrology or combustion chamber analysis, accuracy below one micrometre has been demonstrated. Such capabilities far surpass those of most consumer-grade devices and many competing 3D scanning technologies. [2] [5]

Volumetric accuracy — a key measure of performance indicating how error accumulates over larger measured volumes — is well documented in commercial models. Go!SCAN SPARK, for instance, achieves a volumetric accuracy of 0.050 mm plus 0.100 mm per meter, allowing precise scans of large-scale objects. Meanwhile, scan resolution and rate vary: Go!SCAN SPARK has a 0.100 mm measurement resolution at up to 1.5 million measurements per second, while Artec Eva Lite provides 0.2 mm resolution and up to 18 million points per second. Performance is affected by object size, ambient lighting, and surface reflectivity or texture, which can influence data quality and completeness. Comparison tables listing major commercial models’ specifications for accuracy, volumetric precision, scan resolution, and point acquisition rate can be highly informative for shoppers and researchers alike. [3] [4] [1]

Applications

Structured‑light scanning finds applications across numerous sectors, including:

- Industrial inspection of parts and assemblies

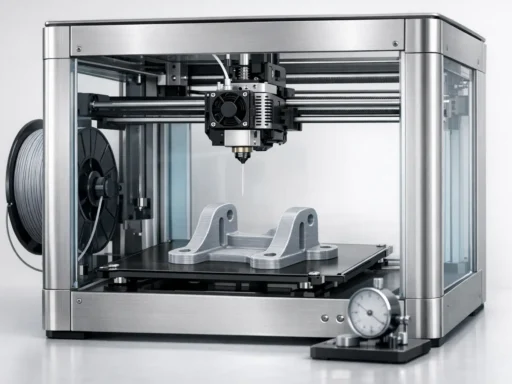

- Additive manufacturing quality assurance

- Documentation and preservation of cultural heritage artifacts

- Medical imaging, dental and orthopedics

- Augmented reality and digital modeling

- Automotive engineering, e.g., precise combustion chamber measurement

Such versatility is enabled by the technology’s non-contact nature, fast data capture, and high-precision results, making it a mainstay for rapid, accurate 3D measurement. [1]

Research Updates

Recent advances include deep learning–based refinements, such as LineMatchGAN, which reduce optical flow error from 0.05 to 0.01 pixels, and new fringe-based 3D reconstruction algorithms surveyed in MDPI’s 2025 review. These developments are accelerating accuracy, automation, and ease of use in structured-light 3D technology. [6] [7]

Q&A

1. What is the typical accuracy of a structured light 3D scanner?

Modern structured-light 3D devices offer typical accuracy between 0.05 and 0.1 mm, while advanced setups can achieve sub‑micrometre results for small-object metrology or specialized tasks. [2] [5]

2. How does a white light scanner differ from laser scanning?

White light, or structured-light, scanners project a broad pattern (often visible or LED light), rapidly capturing large areas with high density and low heat risk. Laser scanners use a focused laser line or dot; they can excel on reflective or dark materials, but may be slower or require more passes for full coverage. [5]

3. How fast can a fast 3D scan by structured-light run in points per second?

Cutting‑edge structured‑light 3D scanners acquire data at rates up to 18 million points per second (Artec Eva Lite), with several professional models reliably capturing over 1.5 million measurements per second. [3] [4]

4. What are the advantages of phase‑shifting structured light over Gray‑code?

Phase‑shifting structured light offers higher spatial resolution and finer surface detail; its vertical resolution can approach 1/50 pixel accuracy, and its lateral detail can go below 1 μm, far exceeding Gray‑code methods for sub‑micrometre and metrological tasks. [1]

5. How do model specifications—such as Go!SCAN SPARK or Artec Eva Lite—impact metrology workflows?

Higher volumetric accuracy, finer resolution, and faster scan rates directly enhance metrology throughput and part confidence. For example, Go!SCAN SPARK’s 0.050 mm volumetric accuracy and 1.5 M measurements/s enable large component analysis with minimal cumulative error, while Eva Lite’s throughput supports rapid object digitization. [3] [4]

Sources

- Wikipedia — Structured‑light 3D scanner

- Wikipedia — Structured light

- Creaform Go!SCAN SPARK specifications

- Artec Eva Lite scanner specifications

- Structured light vs laser scanning — comparison article

- LineMatchGAN: Deep learning for structured-light optical flow (ISPRS)

- MDPI Sensors — 2025 Review: Fringe-based structured-light developments