Summary

Stereolithography (SLA) printing is a type of resin 3D printing that uses a process called vat photopolymerization, where liquid photopolymer resin is selectively cured layer by layer using UV light. Developed in the 1980s, SLA is recognized for its high dimensional accuracy, fine layer resolution, and superior surface quality, making it a leading additive manufacturing technology for prototypes, dental models, and intricate components. [1][2]

Historical Background

Hideo Kodama of Japan outlined the first concept for laser-based resin 3D printing in 1981, but it was Chuck Hull who coined “stereolithography,” filed its patent in 1984, and co-founded 3D Systems to commercialize the technique. [1][2][3]

French inventors independently developed similar approaches in the early 1980s, but it was 3D Systems that released the first commercial SLA printer — the SLA-1 — in 1987, setting the stage for modern resin-based 3D printing. Early adoption focused on rapid prototyping, allowing engineers to quickly fabricate concept models and check fit, form, and function before mass production. As the technology matured, refinements in optics, resin chemistry, and automation allowed SLA to expand into dental, medical, and industrial applications, furthering its reputation for precision and detail. [4]

Technical Principles

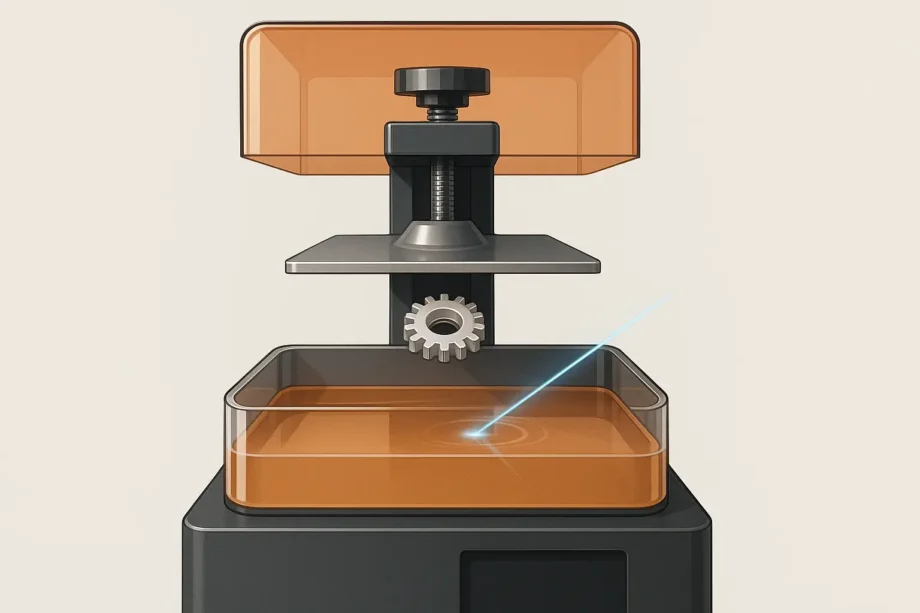

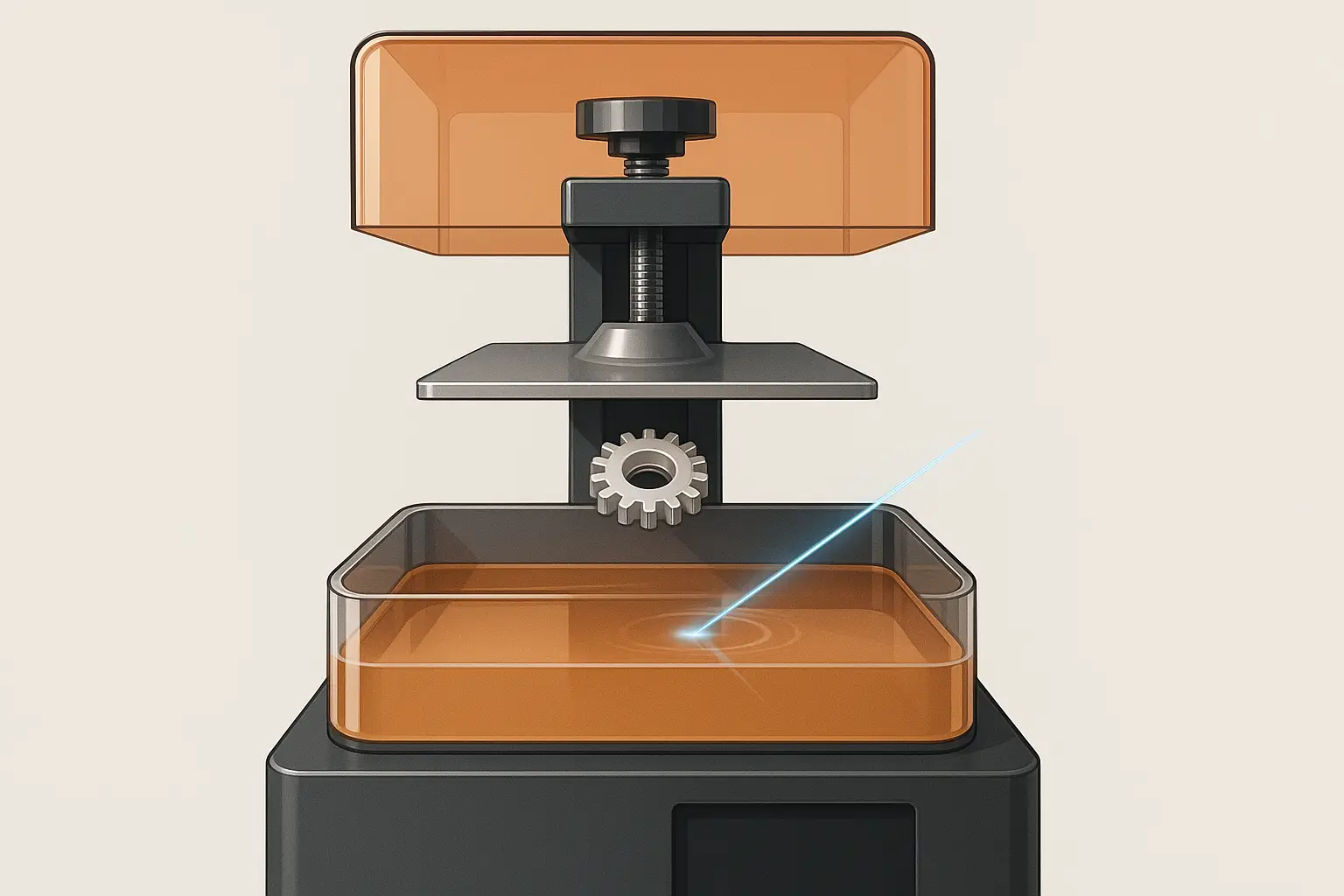

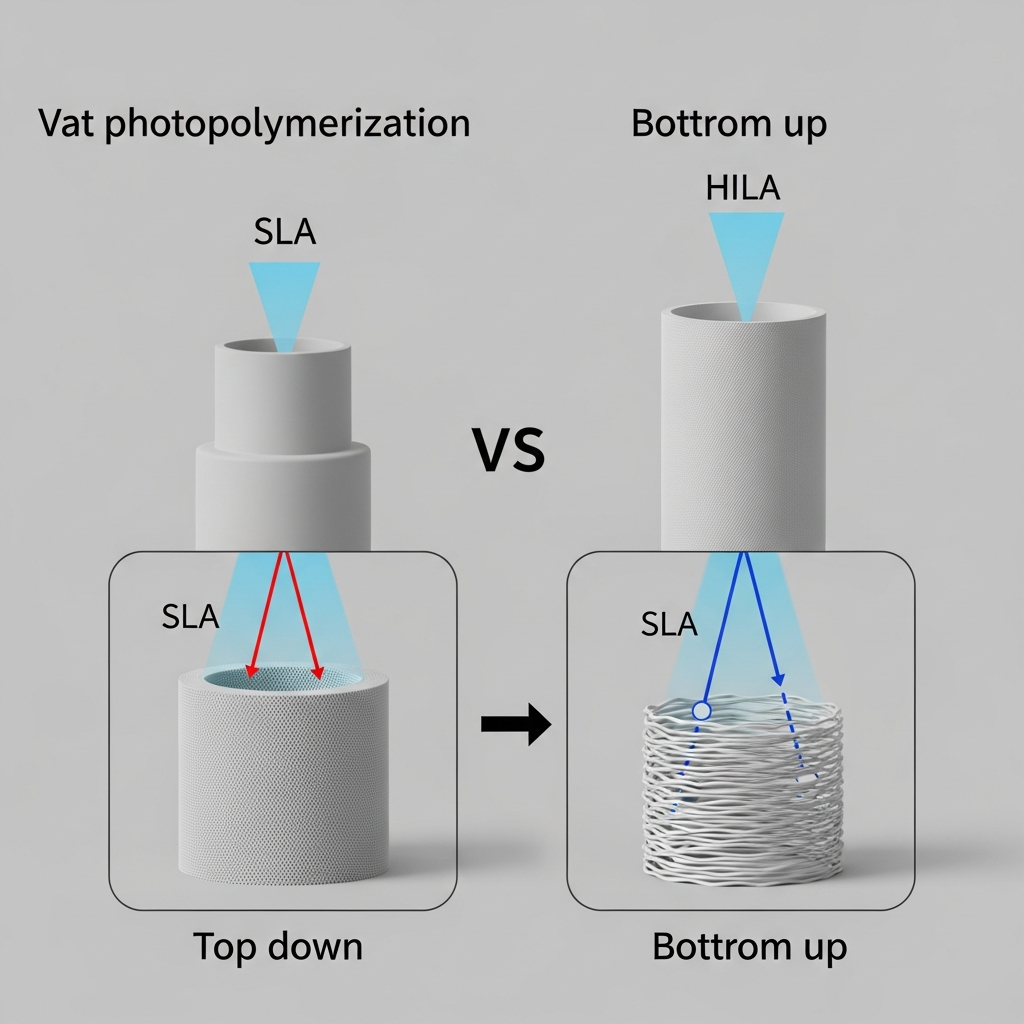

SLA printing utilizes vat photopolymerization, where a build platform is incrementally submerged in a tank of liquid photopolymer resin and a UV laser or projector selectively cures each cross-sectional layer of a 3D model. Traditional “top-down” setups lower the platform into the resin, while “bottom-up” architectures lift the object out as layers solidify on a transparent base. Multiple categories of resins offer options in color, mechanical properties, and biocompatibility. Innovations like Continuous Liquid Interface Production (CLIP) and High-Area Rapid Printing (HARP) provide further enhancements, allowing continuous rather than stepwise curing for vastly increased speeds and larger part sizes. [12]

Performance

Industrial SLA printers regularly achieve minimum feature sizes down to 10 µm and typical layer thicknesses as fine as 25 µm, ensuring excellent detail and surface smoothness. Standard layer resolutions for commercial SLA systems are commonly around 25 µm, with design guidelines stating “normal” at 0.1016 mm, “high” at 0.0508 mm, and “micro” at 0.0254 mm. In terms of dimensional accuracy, industrial SLA reaches ±0.2% or as tight as ±0.13 mm; leading desktop units offer ±0.5% to ±0.10 mm. For example, official Formlabs specifications list tolerances of ±0.15% for parts 1–30 mm (minimum ±0.02 mm), ±0.2% for 31–80 mm (minimum ±0.06 mm), and ±0.3% for 81–150 mm (minimum ±0.15 mm). In dental model benchmarking, 99.7% of surfaces were within 100 µm, 95% within 50 µm, and 69% within just 25 µm of nominal. These figures confirm that SLA printing provides exceptional geometric fidelity and surface finish compared to other 3D printing methods. [5][6][7]

Print speed for standard Masked SLA (MSLA) averages approximately 40 mm/h; however, CLIP and HARP continuous processes can reach printing speeds up to 100 times faster, with up to ~4 000 mm/h reported in laboratory settings. [8]

Build Size and Design Considerations

SLA printers are categorized by build volume and resolution: “normal” SLA enables working envelopes up to 736 mm × 635 mm × 533 mm, “high-resolution” models typically offer up to a 254 mm cube, and “micro” systems provide ultra-fine detail for volumes like 127 mm × 127 mm × 63.5 mm. Trade-offs exist between print speed and feature fidelity: higher resolution means thinner layers and longer print times. Design must consider assembly tolerances, support structure removal, and significant post-processing for best results. Layer thickness varies by resolution—from 0.1016 mm (normal) down to 0.0254 mm (micro). [9][10]

Design considerations:

- Resolution vs speed requirements

- Tolerance/accuracy for assembled parts

- Support structure complexity and removal

- Post-processing steps (curing, cleaning, finishing)

Comparisons

Compared to Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS), SLA offers superior resolution and smoothness. SLA accuracy is typically ±0.05–0.1 mm, outperforming FDM (±0.1–0.3 mm) and SLS (±0.1–0.2 mm), with surface finishes as fine as Ra 1–5 µm, much smoother than FDM (20–100 µm) or SLS (10–20 µm). Build speed for SLA is 20–50 mm/h on average, which is slower than SLS and comparable to or somewhat slower than high-end FDM for large volumes, but vastly outpaced by new continuous resin techniques. [11]

| Technology | Accuracy | Surface finish (Ra) | Typical build speed (mm/h) |

|---|---|---|---|

| SLA | ±0.05–0.1 mm | 1–5 µm | 20–50 |

| FDM | ±0.1–0.3 mm | 20–100 µm | 50–150 |

| SLS | ±0.1–0.2 mm | 10–20 µm | 20–60 |

Research Updates

High-Area Rapid Printing (HARP), introduced in 2019, is a breakthrough continuous SLA process. It achieves rapid, large-scale resin printing by maintaining a nonstick interface, enabling higher throughputs and part sizes previously unattainable in classic stepwise SLA. [12]

Q&A (FAQ)

1. What is SLA printing and how does resin 3D printing work?

SLA printing, or stereolithography, is a resin 3D printing technology that uses vat photopolymerization — a UV light source selectively cures layers of liquid resin to create detailed 3D objects. [1]

2. What factors influence SLA printing tolerances and accuracy?

SLA tolerances depend on printer class, resin formulation, and calibration. Typical values range from ±0.05–0.15 mm; industrial printers achieve up to ±0.13 mm, and 99.7% of surfaces may fall within 100 µm in independent dental model studies. [6][7]

3. How fast is resin curing speed in SLA compared to other 3D methods?

Standard MSLA achieves curing speeds of about 40 mm/h, while advanced continuous techniques like CLIP or HARP reach up to ~4 000 mm/h, much faster than traditional systems. [8][12]

4. What are the advantages of SLA printing over FDM and SLS?

SLA excels in fine detail, superior surface finish (Ra 1–5 µm), and high accuracy (±0.05–0.1 mm), whereas FDM and SLS are less precise and rougher on the surface. [11]

5. What build sizes are typical for SLA printers?

Build size categories: normal (up to 736 mm × 635 mm × 533 mm), high-resolution (254 mm cube), and micro (127 mm × 127 mm × 63.5 mm), enabling both large and high-detail parts. [9]

6. What recent breakthroughs have improved SLA and resin 3D printing performance?

The introduction of High-Area Rapid Printing (HARP) in 2019 allowed for continuous, large-format printing at much higher speeds, advancing SLA’s industrial potential. [12]

Sources

- Stereolithography – Wikipedia

- What is Stereolithography? Who invented it and when? – LaserProto

- Stereolithography – Wikipedia IT

- 3D Printing Resin (SLA, UV, etc.): Technology Guide – 3DMag

- What is SLA 3D Printing? – Hubs

- Formlabs 3D Printing Tolerance and Accuracy – 3DMag

- 3D Printing Resin Accuracy Benchmark, Dental Model Study – 3DMag

- Formlabs Print Speed and CLIP/HARP – 3DMag

- 3D Printing Design Guidelines – MFG Machined

- Stereolithography Revolution: The Future of SLA – Mold7

- SLA vs FDM vs SLS Comparison – Mold7

- High-area rapid printing – Wikipedia