Summary

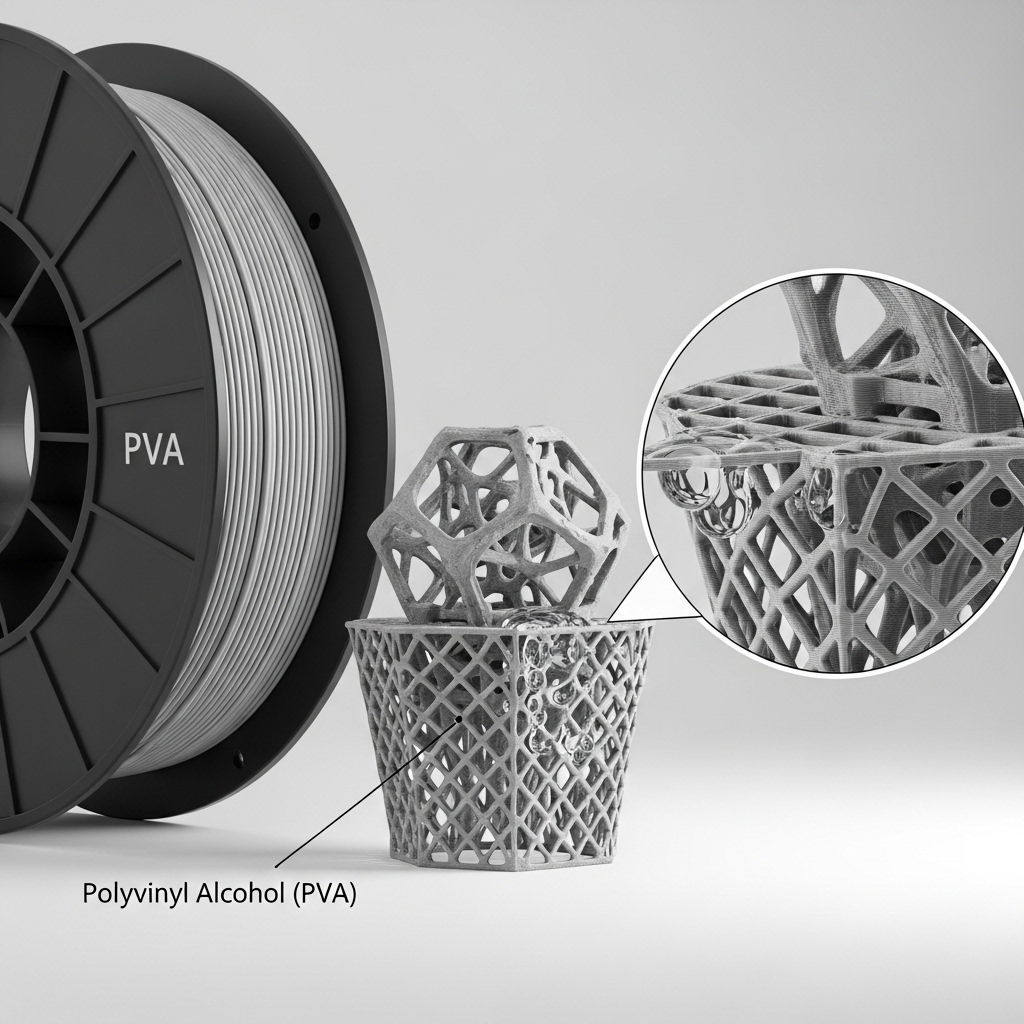

Polyvinyl alcohol (PVA) is a biodegradable, water-soluble thermoplastic polymer commonly employed as a support material in multi-extrusion fused filament fabrication (FFF) 3D printing. Characterized by a melting point of 175.4 °C, water solubility, and greater than 90 % biodegradation within 56 days, PVA supports enable detailed, complex prints with easier removal compared to traditional breakaway supports. [3][11][12]

Historical Background

PVA was first synthesized in 1924 by German chemists Hermann and Haehnel through the hydrolysis of polyvinyl acetate (PVAc). It quickly gained industrial prominence due to its unique solubility and film-forming properties, spawning uses in textiles and coatings. [12]

The adoption of PVA in 3D printing began with specialty filament producers such as Formfutura and Sigma-Aldrich, who developed water-soluble filaments tailored for desktop FFF printers, introducing reliable and precise support strategies for dual-extrusion systems. [1]

Technical Principles

PVA’s utilization in FFF 3D printing rests on its distinct chemical and thermal profile. The glass transition temperature (Tg) varies depending on formulation—UltiMaker datasheets cite 58.4 °C, while iwe3d notes an onset at 85 °C. Melting temperature similarly varies, noted as 175.4 °C (UltiMaker) and 190 °C (iwe3d). Melt flow rate (MFR) typically falls within 14–21 g/10 min. This variability reflects underlying differences in molecular weight and processing methods between manufacturers. Users are encouraged to reference the following comparative table for common datasheet values:

Table: Comparison of PVA Support Material Properties

| Property | UltiMaker | iwe3d | Formfutura |

|---|---|---|---|

| Glass Transition (°C) | 58.4 | 85 | — |

| Melting Temp (°C) | 175.4 | 190 | — |

| MFR (g/10 min) | 17–21 | — | 14–20 |

Datasheet values from manufacturers such as UltiMaker tend to be more reliable for printer-specific calibration, though users should verify with their chosen brand. [3][4][9]

PVA’s mechanical and physical properties further influence its support function. The density of generic PVA used in filaments is 1.19 g/cm³, which aligns with broader polyvinyl alcohol values of 1.19–1.31 g/cm³. The Young’s modulus registers at 2.0 GPa, indicating moderate stiffness, while the ultimate tensile strength reaches 55 MPa, providing sufficient structural integrity for supporting complex overhangs while remaining amenable to water-based removal. [6][7][8][12]

Summary list of thermal vs mechanical properties:

- Thermal: Glass transition (58.4–85 °C), melting temperature (175.4–190 °C), MFR (14–21 g/10 min)

- Mechanical: Density (~1.19 g/cm³), Young’s modulus (2.0 GPa), tensile strength (55 MPa)

Performance

Extrusion Behavior

PVA support materials are engineered for predictable extrusion during 3D printing. Typical filament diameter is 2.85 ± 0.10 mm, suited for desktop systems. Manufacturers list melt flow rates from 14 to 21 g/10 min, with recommended hotend temperatures ranging from 180 °C to 220 °C, ensuring compatibility with standard FFF dual-extruder printers. Consistent diameter and flow help minimize print interruptions and ensure smooth, continuous supports for demanding geometries. The density of 1.19 g/cm³ mirrors established thermoplastic baselines, aiding reliable layer adhesion when paired with common build materials such as PLA or PETG. [1][2][3][6]

Solubility and Biodegradation

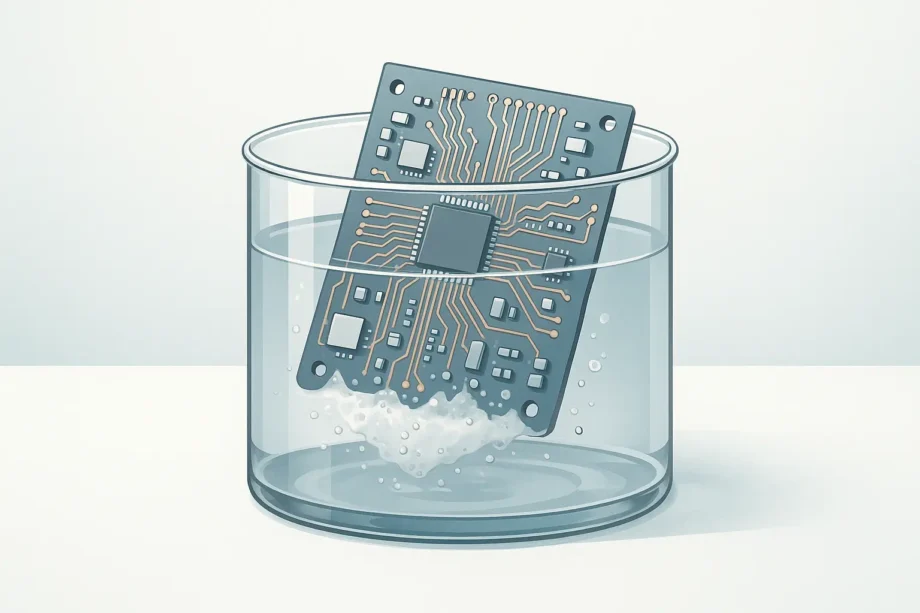

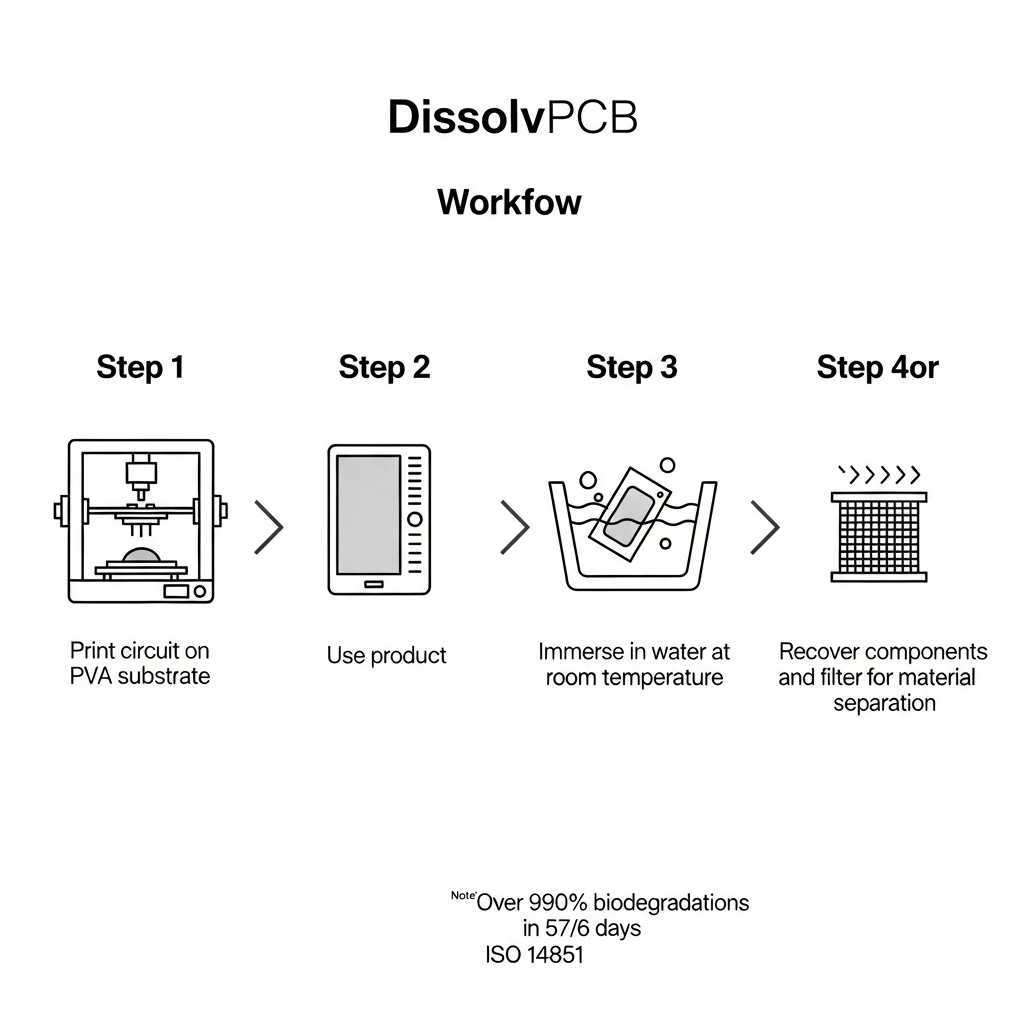

The defining feature of PVA is its rapid solubility in water at room temperature, which allows for non-destructive removal of even internal, intricate supports. Kuraray MOWIFLEX™ PVA variants demonstrate over 90 % biodegradation within 56 days (ISO 14851), surpassing most synthetic thermoplastics in environmental performance. Beyond disposal advantages, PVA’s solubility underpins advanced recycling solutions: for example, in the DissolvPCB initiative, entire electronic assemblies printed on PVA substrates can be dissolved post-use, enabling full material recovery and waste minimization—a process increasingly relevant for sustainable electronics. [11][13]

Applications

Standard uses of PVA support material are concentrated in the domain of complex 3D prints with severe overhangs, internal cavities, or unsupported bridges. As a sacrificial support, PVA pairs particularly well with PLA, PETG, and nylon in dual-extruder setups—enabling clean, undamaged objects, including moving assemblies and detailed architectural models. [5]

Advanced applications span several high-precision or sustainability-focused fields. In bioprinting, PVA constructs sacrificial vascular channels that dissolve after tissue maturation. Pharmaceutical device manufacturing leverages PVA’s safety and solubility for drug delivery research. The DissolvPCB project demonstrates the polymer’s utility in recyclable electronics: complex printed circuits are temporarily supported on PVA, then easily recovered by immersion and filtration, supporting a circular manufacturing model. [13]

Summary list: Standard vs advanced applications

- Standard: Support for overhangs, bridges, internal cavities (PLA, PETG)

- Advanced: Bioprinting (sacrificial channels), pharmaceutical devices, recyclable 3D-printed electronics

Research Updates

Recent developments center on leveraging PVA’s water-solubility and biodegradability for greener electronics manufacturing. In 2025, DissolvPCB researchers demonstrated a method for fabricating 3D-printed circuit boards fully supported by PVA substrates. These substrates enable efficient component separation and total dissolution post-lifecycle, allowing for complete recycling of valuable metals and polymers. This advancement highlights PVA’s emerging importance in “dissolvable device” architectures, offering a scalable pathway to reduce e-waste and close material loops in future electronics production. [13]

Frequently Asked Questions (FAQ)

1. What is PVA support material used for in 3D printing?

PVA is primarily used as a water-soluble support material in multi-extrusion 3D printing, enabling the fabrication of complex geometries with overhangs and internal structures that would be impossible to produce with breakaway supports alone. [5]

2. How does PVA filament dissolve after printing?

Once printed, PVA supports are removed simply by immersing the object in water, where the polymer dissolves—allowing non-destructive separation even of enclosed or inaccessible features. [11]

3. What are the thermal parameters (glass transition and melting) of PVA support materials?

Manufacturers report a glass transition temperature between 58.4 °C and 85 °C, and a melting temperature from 175.4 °C (UltiMaker) to 190 °C (iwe3d), depending on formulation and source. [4][9][10]

4. How stiff and strong is PVA support material (expert-level)?

PVA filament exhibits a Young’s modulus of 2.0 GPa and a tensile strength of 55 MPa, which delivers stability for supporting features during the print process, yet easy dissolution afterward. [7][8]

5. What are the environmental benefits of using PVA supports?

PVA is biodegradable, with over 90 % decomposition in 56 days under laboratory conditions. Its solubility offers benign waste removal and supports recyclable design principles in advanced manufacturing. [11]

6. How is PVA used in advanced applications like recyclable electronics (expert)?

Recent research, such as the DissolvPCB project, employs PVA as a dissolvable substrate for 3D-printed electronics, enabling the entire assembly—including embedded components—to be recycled after immersion in water. [13]

Sources

- Sigma-Aldrich PVA Filament (Formfutura AquaSolve) Specifications

- Sigma-Aldrich (Formfutura) Material Data

- UltiMaker PVA Technical Data Sheet

- UltiMaker PVA Thermal Properties

- UltiMaker PVA Applications Overview

- iwe3d PVA Filament Data Sheet

- iwe3d PVA Filament: Mechanical Properties

- Divbyz: PVA Filament Technical Guide

- iwe3d PVA Glass Transition and Melting Point

- iwe3d PVA Melting Onset

- Kuraray: MOWIFLEX™ Biodegradation Data

- Wikipedia: Polyvinyl Alcohol

- arXiv: DissolvPCB—Water-Soluble PVA Substrates for Recyclable 3D-Printed Electronics (2025)